Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

N/M

-

Place of Origin:

-

Shandong, China

-

Thickness:

-

76-92um

-

Particle Size Analysis:

-

38um

-

Pencil Hardness:

-

H-2H

-

Adhesion:

-

Qualified 100/100

-

Spedific Gravity:

-

1.2-1.7g/cm3

-

Curing:

-

180-200degree 10-15mins

-

Shelf Life:

-

12months

Quick Details

-

CAS No.:

-

N/M

-

Other Names:

-

eletrostatic thermosetting powder

-

MF:

-

-[-ch2ch2o-]n-

-

EINECS No.:

-

N/M

-

Place of Origin:

-

Shandong, China

-

Thickness:

-

76-92um

-

Particle Size Analysis:

-

38um

-

Pencil Hardness:

-

H-2H

-

Adhesion:

-

Qualified 100/100

-

Spedific Gravity:

-

1.2-1.7g/cm3

-

Curing:

-

180-200degree 10-15mins

-

Shelf Life:

-

12months

Carbon steel pipe floor powder epoxy powder coating to malaysia

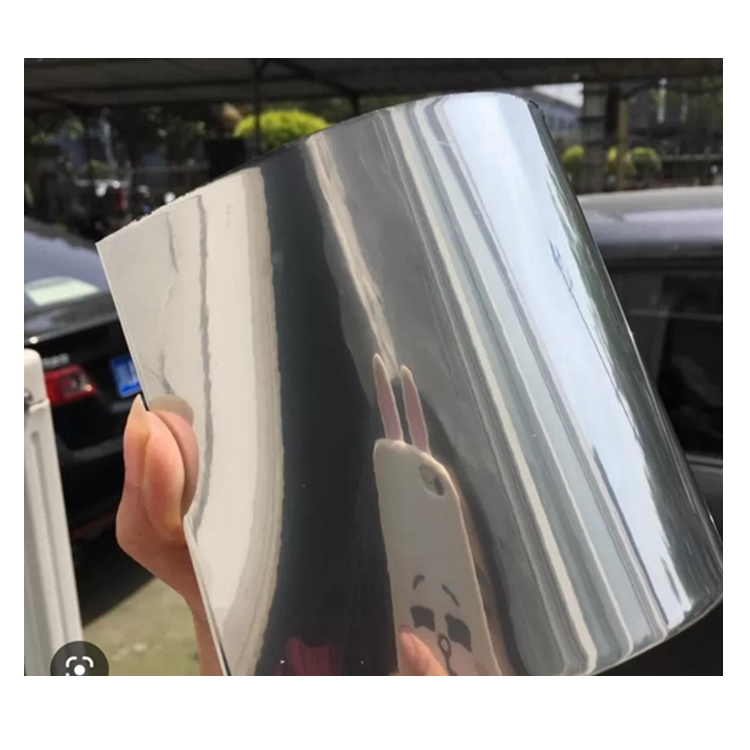

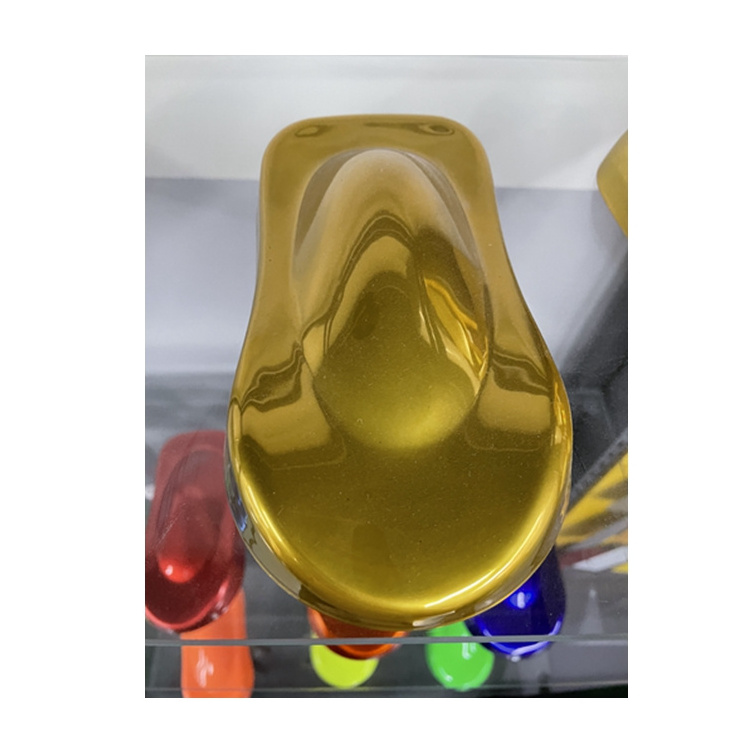

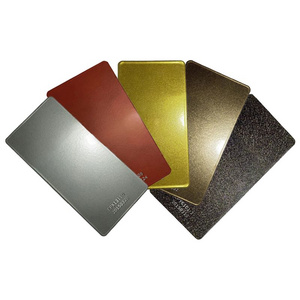

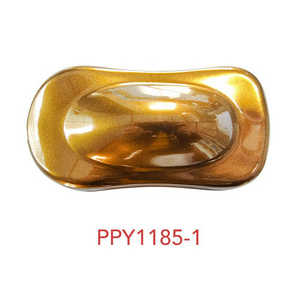

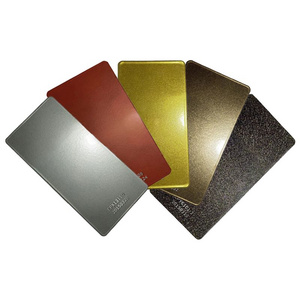

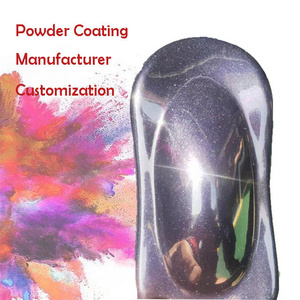

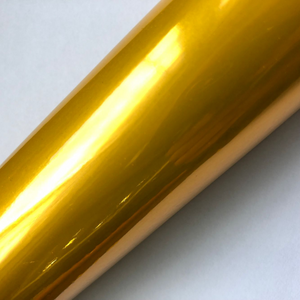

Silver and Gold Color Metal Color Chrome Powder Coating with CE

1. Our Powder Coating Advantage:

(1) Spray ratio is 90%;

(2) 1KG of powder coating can spray 8-10 square meter;

(3) Powder Coating adhesive force is stronger 8-10 years;

(4) Powder Coating is not easy to fade in 5-8 years;

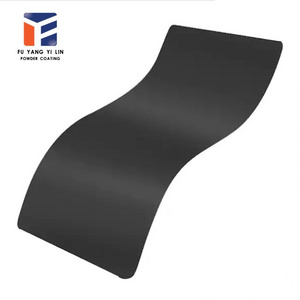

2. Charactcristic: Powder

|

Available Powder Types |

Available Colors |

|

1. Epoxy powder coating |

1. RAL Colors |

|

2. Polyester Powder Coating |

2.Pantone Colors |

|

3.Epoxy-Polyester Powder Coating( Hybrid) |

3.Customer color matching |

|

4.Polyurethane Powder Coating |

Available finish |

|

5.Heat transfer printing powder coating |

1. Smooth |

|

Available gloss level |

2. Rough( Sand texture ) |

|

1. High gloss( Above 80%) |

3.Wrinkle( fine texture ) |

|

2. Flat gloss (50%-80%) |

4.Antique( hammer tone) |

|

3. Semi gloss(5%-50%) |

5.Metallic |

|

4. Matt ( below 5%) |

6.Other special effect ( artistic) |

3. How to use it?

|

Bad symtoms |

Possible Cause |

Solution |

|

1.With low power, powder coating is not easy to coated;

|

1. High voltage power supply shortage; |

1. Check the circuit |

|

2. Grouding is bad; |

2. Remove clutter grouding line |

|

|

3. Compressed air volume is too big, the powder to blow fell &blows away; |

3. Spray appropriate isolation, reduct air convection; |

|

|

4. Powder particle size is too thin; |

4. Add new powder coating, reduce the recovery powder consumption. |

|

|

5. The air temperature is too high; |

5. Powder particles with air water branch of low power, control temperature of spray area; |

|

|

2. Charge repulsion powder repboud from the working surface; |

1. The voltage is too high; |

1. Lower voltage and air volume; |

|

2. Spray gun from the work location is too close; |

2. Extend the spray gun and artifacts; |

|

|

3. Grouding is bad; |

3. Remove clutter grouding line; |

|

|

4. Powder particle size is too thin, not esay to attach to the workpiece surface; |

4. Add new powder coating, reduce the recovery powder consumption; |

|

|

3. Corner not easy spraying penetration is bad; |

1. The powder amount is too small; |

1. Lower voltage and air volume, increasing the amount of powder; |

|

2. Grouding is bad; |

2. Adjust the spray gun position; |

|

|

3. The voltage is too high; |

3. Choose small backboard, proper nozzle; |

|

|

4. Spray gun position is not good; |

4. If the corner is more and deeper, then consider friction gun equipment; |

|

|

5. Powder spraying range is too wide; |

||

|

4.Powder spraying uneven |

1. Air pressure is insufficient; |

1. Cleaning pipeline, spray gun and flowmeter; |

|

2. Line fault block; |

2. Check the air supply, Exclude water vapor in powder agglomeration; |

|

|

3. Block in the spray gun; |

3. If powder agglomeration, to screen or change new powder coating; |

4. Effect of Sample

Our Powder Coating Advantage:

1.1KG of powder coating can spray 8-10 square meter;

2.Spray ratio is 95 %;

3.Powder coating adhesive force is stronger 8-10 years;

4.Powder coating is not easy to fade in 5-8 years;

|

Card Types |

Color Category |

|

1. RAL Cards |

213 kinds of colors |

|

2. PANTONE Cards |

1690 kinds of colors |

|

3. FRD Cards |

360 kinds of colors |

5. How to choose the product you like?

Our service

1. We offer professional products and fast delivery.

2. We will help you solve problems when you use our products.

3. Any question can turn to the technology department of our company.

6. Powder Coating Application:

Our Product specially designed for surface decoration product such as home furniture,

electrostatic appliance, industrial equipment, sports equipment, harware, shop tool

rack, lamps and lanterns, computer chassics, DVD sheel, etc.

|

Application Area |

|

|

1. Household Applications |

7. Used for Security Door; |

|

2. Car Coating |

8. Radiator & Heat Sink; |

|

3. Used for Valve |

9. Corrosion Prevention of Pipes; |

|

4. Track Traffic |

10. Communications Equipments; |

|

5. Aerospare field |

11. Hardware & Brightwork; |

|

6. Fitness Equipment |

|

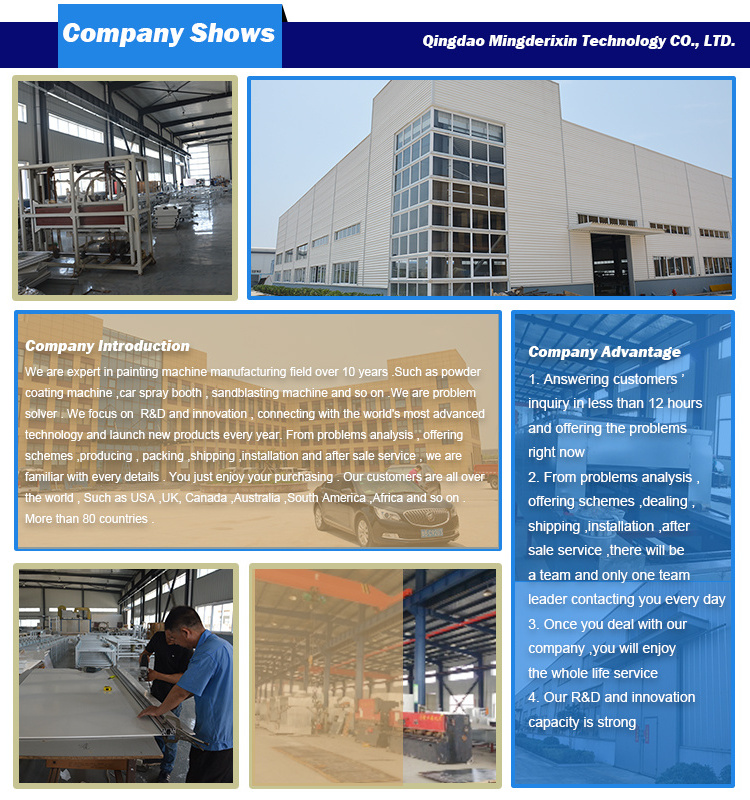

Factory