- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

Type

-

Size:

-

Type

-

Power:

-

Type

-

Product name:

-

Automatic PAM PAC Polymer Powder Dosing System

-

Capacity:

-

250L~10000L/H

-

Usage:

-

Purifying

-

Application:

-

Waste Water Treatment

-

Certification:

-

ISO9001

-

Function:

-

Auto Polymer Preparation

-

Type:

-

Assembled

-

MOQ:

-

1 Set

-

Keywords:

-

Powder Dosing system

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Ainfo

-

Material:

-

Metal/Plastic, Stainless Steel

-

Weight:

-

Type

-

Size:

-

Type

-

Power:

-

Type

-

Product name:

-

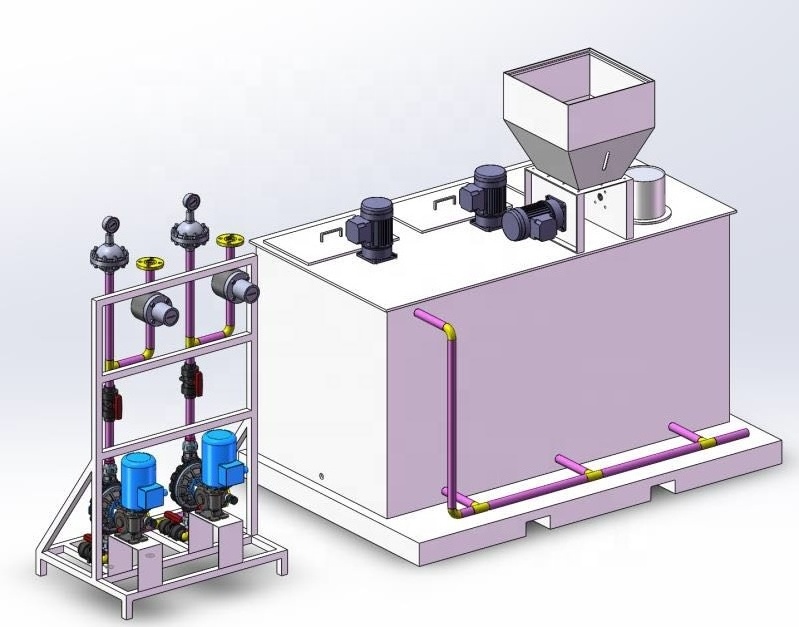

Automatic PAM PAC Polymer Powder Dosing System

-

Capacity:

-

250L~10000L/H

-

Usage:

-

Purifying

-

Application:

-

Waste Water Treatment

-

Certification:

-

ISO9001

-

Function:

-

Auto Polymer Preparation

-

Type:

-

Assembled

-

MOQ:

-

1 Set

-

Keywords:

-

Powder Dosing system

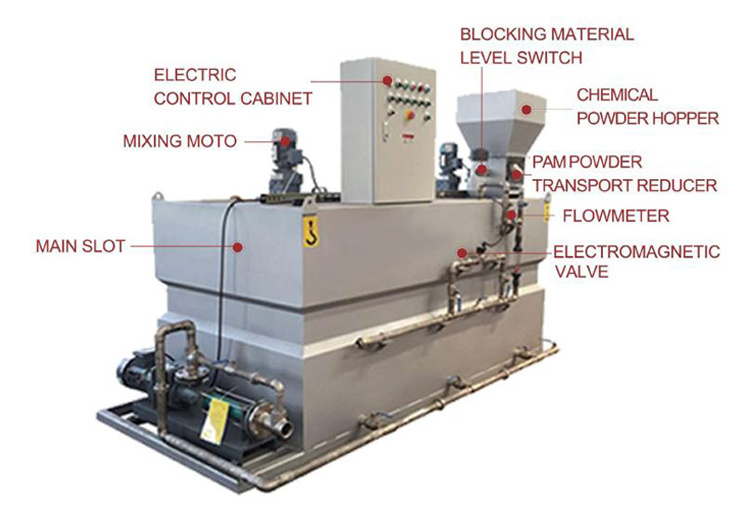

Introduction:

·

Automatically Operate

·

The amount of the powder feeding is exactitude

·

SUS304/PP crust, all imported parts

·

Easyto maintain

· All message is output by touch

With the dosing units you can easily and reliably condition the water to serve the intended use and to meet the technical requirements. The field of applications includes the dosing of:

* Acids for alkalinity reduction and scale prevention

* Polyelctrolytes for coagulation of suspended solids and an improved subsequent filtration

* Scale inhibitors to avoid scale deposits on reverse osmosis membranes

* Disinfectants for shock treatment in order to avoid bacterial growth

* Chlorine to avoid biological growth in pipes and storage tanks

* Hydrated lime or caustic soda for pH adjustment to neutralize dissolved free carbon dioxide.

Application:

Aid condensation of city sewage

Aid condensation of industry sewage

Disposal and deposit of sludge

Calcareousness feeding

Features:

* high dosing accuracy.

* local control for adjustment of dosing rate.

* integral dosing head deaeration.

* for degasing of chemicals.

* easy installation and maintance.

* high operational reliability.

* high quality materials.

* accessories in great variety.

(

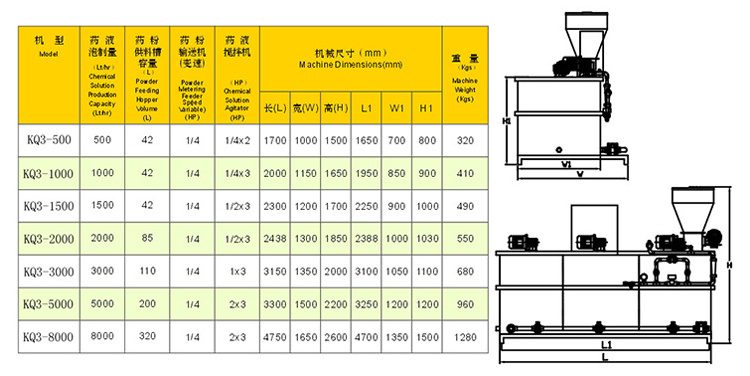

All customized models are available by online inquiry

).

The ordering process:

1. inform us of the need for the added chemicals, water treatment capacity on site, detailed drawings issued by the installation site requirements we give

2. quotation

3. your company confirm our quotation reasonable

4. negotiation details

5. orders and pay

6. drawing the picture and production

|

|

|

|

|

|