- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1130*1480*2450mm

-

Model Number:

-

J23

-

Weight (T):

-

3.1

-

Warranty of core components:

-

24 months

-

Product name:

-

Mechanical inclinable press machine

-

inclinable punching press machine:

-

J23

-

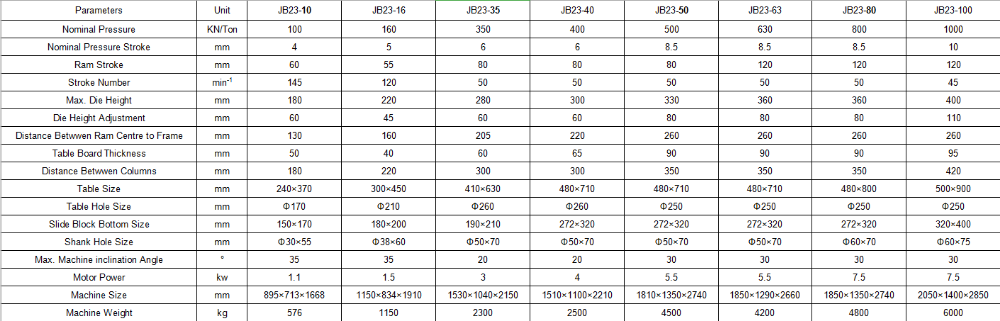

Stroke of sliding block(mm):

-

100

-

Number of strokes(times/min):

-

50

-

Maximum Closed height(mm):

-

350

-

Closed height adjustment:

-

80

-

Die hole(diaxdep):

-

50*70mm

-

Application:

-

Metal Sheet Stamping

-

Weight:

-

3.1ton

-

Power:

-

5.5 KW

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

rbqlty

-

Voltage:

-

220V/380V/415V/440V/400V

-

Dimension(L*W*H):

-

1130*1480*2450mm

-

Model Number:

-

J23

-

Weight (T):

-

3.1

-

Warranty of core components:

-

24 months

-

Product name:

-

Mechanical inclinable press machine

-

inclinable punching press machine:

-

J23

-

Stroke of sliding block(mm):

-

100

-

Number of strokes(times/min):

-

50

-

Maximum Closed height(mm):

-

350

-

Closed height adjustment:

-

80

-

Die hole(diaxdep):

-

50*70mm

-

Application:

-

Metal Sheet Stamping

-

Weight:

-

3.1ton

-

Power:

-

5.5 KW

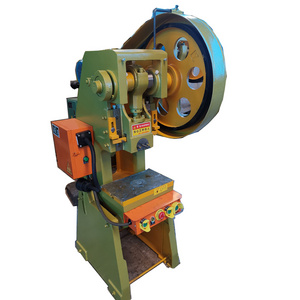

J23 Series open back inclinable mechanical press machine.

1. J23 series Open Eccentric Presses is a general-purpose presses, suitable for forming, blanking, punching, bending and other cold stamping process.

2. C-frame Casting fuselage,maximum rigidity and minimum deflection for accurate parts and long tool life. body can be tilted, , high rigidity and less deformation Compact. Thick plates and large columns provide you with the stable platform you need for your demanding application.

3. The Machine use Rigid rotated bond clutch rigid and well supported. The clutch gives continuous strokes for mass production.

4. Crank shaft is made of special alloy steel machined to close accuracy and fitted in bronze bushes for smooth working, longer life & accuracy.

5. Properly sized flywheel, is made of high grade cast iron, for storing and releasing adequate energy for the pressing operations, and properly balanced for smooth running.

6. Gear are of steel cast or fabricated. Gear teeth are generated by precision hobbing machine.

7. Machine is with both hands button and foot switch control: anti-tie down, non-repeat controls with ring guards; conforms to OSHA.

8. Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,easy to operate.

Inclinable mechanical press machine

Machines in stock

Machines frames are ready in stock

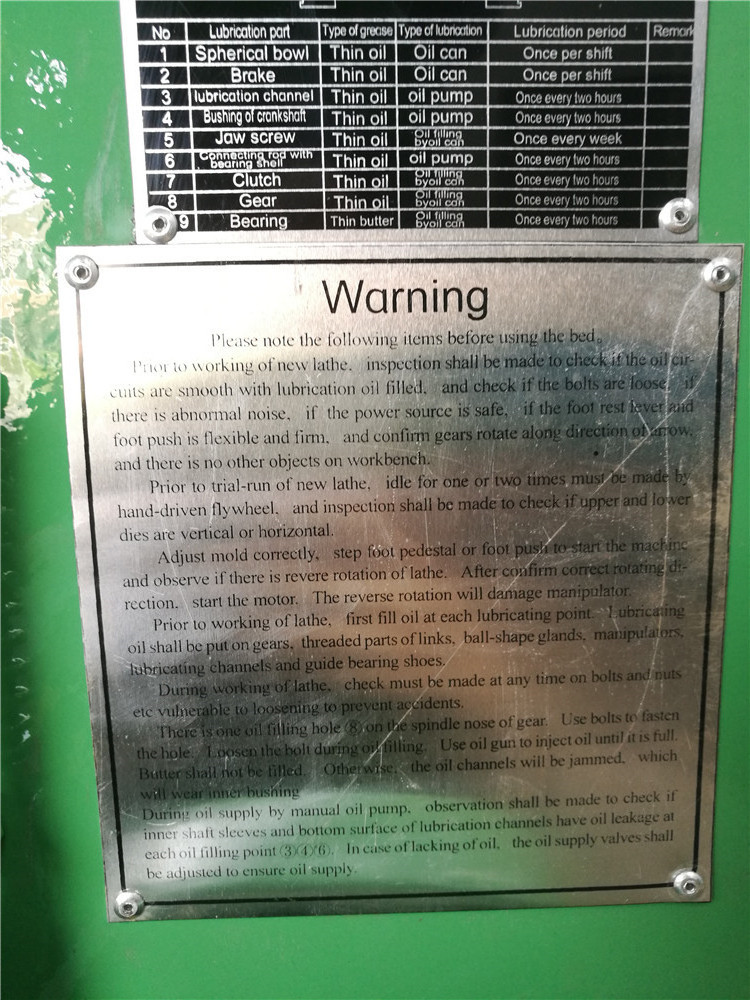

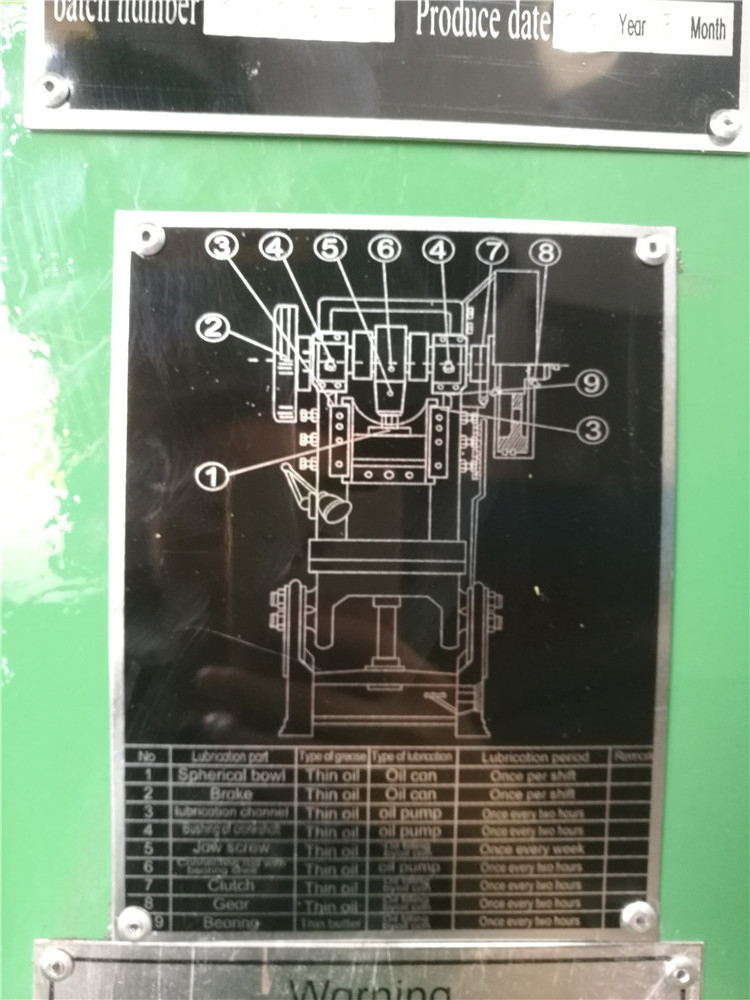

Warning sign

The machine net weight

accurate and precise

Motor type

Adjustable screw

Control the machine inclined angle

Belt pulley

Lubrication device

precise transmision and sychronization

Lead time

4 to 8 mm plate shear 15 days

10 to 50 mm plate shear 20 to 40 days

Payment Method

30% T/T in advance, the balance paid before shipping

irrevocable L/C at sight

|

Packaging

|

|

|

|

Size

|

length 1.6 to 8 meter

width 0.8 to 2.5 meter

height 1.8 to 4 meter

|

|

|

Weight

|

From 3 ton to 20 ton

or above according to model

|

|

|

Packaging Details

|

Plastic film packge

plywood box package

|

|

|

Delivery Details

|

FCA to your consignee

FOB PORT to Shanghai

CIF PORT in your country

|

|

Anhui Runbang Heavy Industry Machinery Co., Ltd.

MTCNC concentrates on the research, development, manufacture, sale and service in metal fabrication equipment.

MTCNC not only supplies metal sheet shearing, bending, punching, rolling machine tool. but also provides you complete metal fabrication solution.

Material Stock Part

Warehouse Part

Abundant Stock

How is the lead time?

2 .For standard machine model, we can send machines out within 7 working days;

3. Customized type usually takes around 1 month to do.

How about your after-sale service?

2.Online video: show you machine working video in factory . ( update every month)

3.Installation service: this is available with all of our machines, We dispatch technician to customer's factory for installation machines. (Customers only need to pay for the airfare and hotel expense.)

4.Training service: Our technician will teach you how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

5.Quality guarantee: 1 year warranty, we provide lifetime service. We arrange final test before shipment, After making sure machine is the best performance, then make shipments.

6. 100% response rate: we will reply your questions within 12 hours.