Th

e machine frame is annealed and milled by a large gantry to accurately drill all installation basic holes at once.

Higher tensile strength and dimensional stability. Effectively improve the accuracy of the bed, reduce the processing error of the wo

rkpiece. Increase the resistance and stability of the guide rail. It reduces the loss of the equipment when it is u

sed. It keeps the precision of the cheap laser cutter for a long time and does not deform for 20 years. The affordable laser cutter has good stability and reduces the processing errors caused by the vibration of the bed.

- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

0-40mm

-

Control Software:

-

Cypcut control

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

igoldecnc

-

Weight (KG):

-

2300 KG

-

Key words:

-

cnc fiber laser cutting machine

-

Power supply:

-

380V/50Hz

-

Laser wavelength:

-

1080NM

-

Laser power:

-

500W / 750W / 1000W/1500W

-

Temperature:

-

0℃-40℃

-

Beam quality:

-

<0.373mrad

-

X Y drive way:

-

Imported Japan

-

Transmission:

-

Imported TBI ball screw

-

Repeat positioning accuracy::

-

±0.02mm

-

Function:

-

Cutting Metal Materials

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

0-40000mm/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

0-40mm

-

Control Software:

-

Cypcut control

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

igoldecnc

-

Weight (KG):

-

2300 KG

-

Key words:

-

cnc fiber laser cutting machine

-

Power supply:

-

380V/50Hz

-

Laser wavelength:

-

1080NM

-

Laser power:

-

500W / 750W / 1000W/1500W

-

Temperature:

-

0℃-40℃

-

Beam quality:

-

<0.373mrad

-

X Y drive way:

-

Imported Japan

-

Transmission:

-

Imported TBI ball screw

-

Repeat positioning accuracy::

-

±0.02mm

-

Function:

-

Cutting Metal Materials

Recommend Products

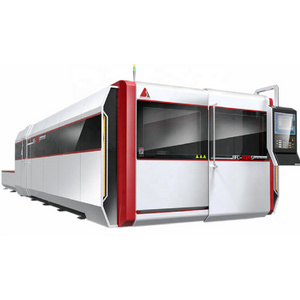

◆

S

afe, high efficiency, energy saving, entry-level metal sheet laser cutting equipment.

◆ H eavy-duty welding frame, aviation aluminum beam and high-efficiency transmission system.

◆ Advanced Cypcut CNC control system, fast cutting speed and high precision.

◆ Good dynamic performance, fast servo response, small thermal effect, especially suitable for sheet metal processing.

◆ H eavy-duty welding frame, aviation aluminum beam and high-efficiency transmission system.

◆ Advanced Cypcut CNC control system, fast cutting speed and high precision.

◆ Good dynamic performance, fast servo response, small thermal effect, especially suitable for sheet metal processing.

Product Description

The design, raw materials and final products of iGOLDENCNC are certified and tested by the widest range of international standards. All core components such as laser source, laser head, rack, guide rail, motors, reducer are selected from hundreds of tests and comparisons to ensure high quality, stability and practicality. The equipment we have provided has been successfully operated in many different working conditions and environments, and it will bring you the most reliable and perfect function to fully satisfy your needs.

Technical Parameters

|

Model

|

IGR-F

|

|

Working area (L*W)

|

3000*1500mm / 4000*2000mm/6000*1500mm (customizable)

|

|

Laser power

|

1000W / 1500W / 2000W / 3000W

|

|

Laser source

|

JPT MAX IPG Raycus

|

|

X axis stroke

|

1530mm

|

|

Y axis stroke

|

3050mm

|

|

Z axis stroke

|

80-120mm

|

|

positioning accuracy

|

±0.03mm

|

|

repositioning accuracy

|

±0.02mm

|

|

Cutting speed

|

0-140m/min

|

|

Max. accelerated speed

|

1.5G

|

|

Power supply

|

380V 50Hz/60Hz

|

|

Cooling method

|

Cooling method

|

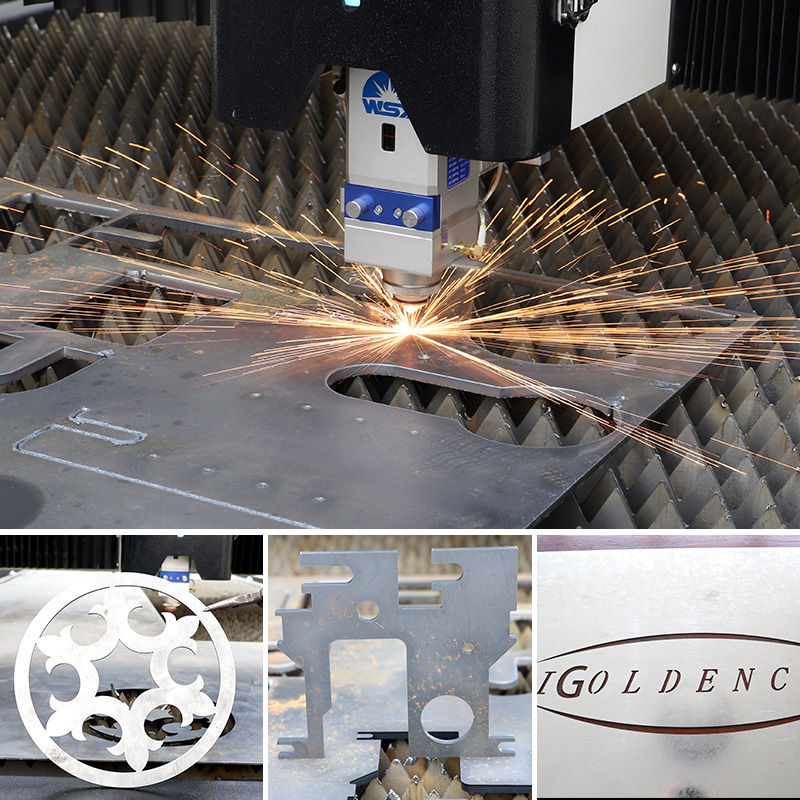

Sample

Cutting materials:

Stainless steel sheet, carbon steel sheet, alloy steel sheet, iron sheet, galvanized iron sheet, galvanized sheet, aluminum sheet, copper sheet, brass sheet, bronze sheet, gold sheet, silver sheet, titanium sheet and other metal sheets.

Application industry:

In recent years, fiber laser cutting machines have been widely used in various manufacturing and processing industries such as aviation, aerospace, automobiles, precision parts, metallurgical processing, and kitchenware processing. Compared with traditional cutting methods, the machine has the advantages of high precision, fast speed and high efficiency.

In recent years, fiber laser cutting machines have been widely used in various manufacturing and processing industries such as aviation, aerospace, automobiles, precision parts, metallurgical processing, and kitchenware processing. Compared with traditional cutting methods, the machine has the advantages of high precision, fast speed and high efficiency.

Details Images

Heavy duty steel welded machine frame

High quality aviation aluminum beam

●

High precision. After manual aging, solution treatment and finishing, the beam has good integrity, rigidity, toughness and ductility.

●

Fast speed. Aluminum alloy has the features of light weight and strong rigidity, which is conducive to high-speed movement during processing, and high flexibility is conducive to high-speed cutting of various graphics on the basis of high precision.

●

High efficiency. The lighter weight beam can ensure the rapid operation of the flatbed laser cutting machine, improve the processing efficiency, and at the same time ensure the processing quality.

Auto focus laser cutting head

The laser head has a built-in motor drive unit, and the focusing lens is driven by a linear mechanism to automatically change the position within 20mm. The user can set continuous focus through the program to complete the rapid perforation of thick plates and automatic cutting of plates of different thicknesses and materials.

Automatic edge seeking function

Auto-induct materials cutting edge and adjust cutting range according to their inclination angle automatically in case any incorrect position.

Flying cutting function

To reduce the change of cutting path, and improve the cutting efficiency, saving working time.

Customer feedback

Why Choose Us

FAQ

Q1: How to choose the right power?

A1:

The power of the machine is determined by materials processed.

You can tell us materials and thickness you want to cut, our professional technicians will recommend the most suitable power for you.

Q2: If we have special needs and want to customize the machine, is this possible?

A2: Yes, please send us your requirements and our engineers will provide you with the suitable solution.

Q2: If we have special needs and want to customize the machine, is this possible?

A2: Yes, please send us your requirements and our engineers will provide you with the suitable solution.

Q3: How do you guarantee quality?

A3: Our products have obtained CE certification. And we have a complete quality inspection process. A machine is only allowed to be packaged if it passes the inspection and there is no problem with the trial operation. And the machine has a two-year warranty.

Q4: Can you arrange the shipment for me?

A4: Yes, of course we can. Our products have been shipped to dozens of countries and regions in the world, and we are very experienced. You can tell us the nearest port to you and the dedicated manager will check the freight for you and help you handle subsequent transportation.

Q4: Can you arrange the shipment for me?

A4: Yes, of course we can. Our products have been shipped to dozens of countries and regions in the world, and we are very experienced. You can tell us the nearest port to you and the dedicated manager will check the freight for you and help you handle subsequent transportation.

Hot Searches