- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

120±10bag/min

-

Weight (KG):

-

4250

-

Voltage:

-

3 phases 380V / 3 phases 220V, 3 phases 380V / 3 phases 220V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

NF(NAN FENG)

-

Dimension(L*W*H):

-

3500mm*1500mm*2400mm(standard)

-

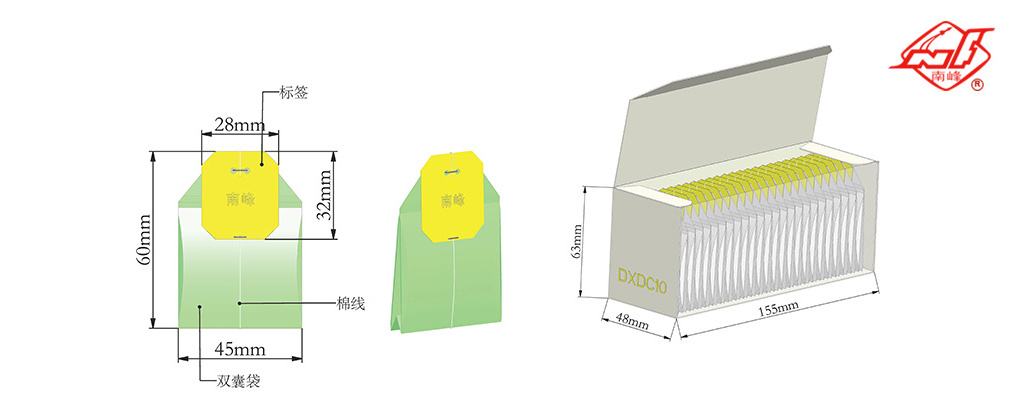

Size of tea bag:

-

45mm*60mm or 40mm*60mm

-

Size of tag:

-

28mm*32mm (Heat sealable tag) / 28mm*24mm (Glue tag)

-

Thread length:

-

148±5mm

-

Size of staple:

-

13mm (5mm after folding)

-

Air pressure:

-

0.6MPa

-

Air consumption:

-

300L/min

-

Optional Devices:

-

Pneumatic vacuum feeder/Date printing device/Complete safety guard etc

-

Carton dimension:

-

2900mm*1950mm*2000mm

Quick Details

-

Function:

-

FILLING, Wrapping, Labeling, Sealing, BOXING

-

Packaging Type:

-

Cartons, Bags

-

Packaging Material:

-

Plastic, Paper, Metal, P.E

-

Production Capacity:

-

120±10bag/min

-

Weight (KG):

-

4250

-

Voltage:

-

3 phases 380V / 3 phases 220V, 3 phases 380V / 3 phases 220V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

NF(NAN FENG)

-

Dimension(L*W*H):

-

3500mm*1500mm*2400mm(standard)

-

Size of tea bag:

-

45mm*60mm or 40mm*60mm

-

Size of tag:

-

28mm*32mm (Heat sealable tag) / 28mm*24mm (Glue tag)

-

Thread length:

-

148±5mm

-

Size of staple:

-

13mm (5mm after folding)

-

Air pressure:

-

0.6MPa

-

Air consumption:

-

300L/min

-

Optional Devices:

-

Pneumatic vacuum feeder/Date printing device/Complete safety guard etc

-

Carton dimension:

-

2900mm*1950mm*2000mm

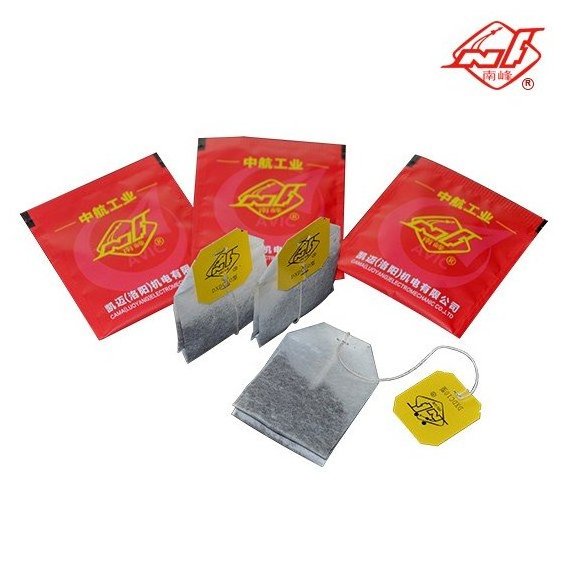

Products Overview

DXDC10 double chamber

tea bag packing machine

The machine DXDC10 is a kind of automatic tea bag machine for th packing of tea and similar Chinese herbs / Flower tea.It makes double chamber tea bags which are cold-sealed.The machine links up hard label and thread with staple,and the tea bags are pushed out and packed into box manually after counting.The packing materials are non-heat-sealed filter paper,label,thread and staple.

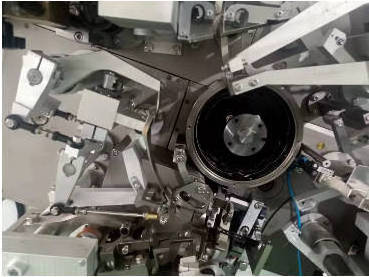

Characteristics

♦

Multi-axis and multi-motor drive are realized by using multiple servo motors, which simplifies the mechanical transmission chain, greatly reduces the mechanical transmission noise, and makes the transmission control more flexible and convenient, and has accurate positioning, stable and reliable operation.

♦

The new measuring structure can adapt to various materials, and the packaging dosage is continuously adjustable and conveniently set. The measurement accuracy reaches ±5%.

♦

Double-chamber cold sealing molding meets the demands of the high-end bag packaging market.

♦

Using hard labels makes the machine more aesthetically pleasing, and the cotton thread is securely connected to the labels and inner bags using patented technology, ensuring stable and reliable operation as well as neat and tidy packaging.

♦

The outer bag forming process has been optimized to achieve a flatter and more attractive appearance. The supply of inner bag rolls, outer bag rolls, and label paper rolls is coordinated through a damping and tension system for improved stability and reliability.

♦

Aluminum nail forming technology ensures a secure connection between the inner bags, labels, and cotton thread.

♦ G

rouped counting output for the inner bags, allowing for manual box packing functionality.

♦

A centralized lubrication system has been implemented to ensure timely and adequate lubrication of all critical points in the system, guaranteeing reliable operation of the entire machine.

Technical data

|

No.

|

Product model

|

DXDC10

|

|

1

|

Capacity

|

120±10bags/min

|

|

2

|

Max.Dosage

|

10cm³

|

|

3

|

Size of tea bag(L×W)

|

45mm×60mm or 40mm×60mm

|

|

6

|

Tag dimensions(LxW)

|

28mmx32mm(heat-sealed)

|

|

7

|

Thread length

|

148±5mm

|

|

9

|

Air pressure

|

0.6MPa

|

|

10

|

Air consumption

|

300L/min (with pneumatic vacuum feeder)

100L/min (without pneumatic vacuum feeder)

|

|

11

|

Voltage

|

3 phases 380V / 3 phases 220V

|

|

12

|

Total power

|

10 KW

|

|

13

|

Overall dimension(LxWxH)

|

3500mm×1500mm×2400mm(standard)

|

|

14

|

Case dimension(LxWxH)

|

2900mm×1950mm×2000mm

|

|

15

|

Net weight

|

4000kg

|

|

16

|

Gross weight

|

4250kg

|

|

17

|

Option

|

Envelope packing machine

|

Product configuration

Filter paper fixing

Tea bag forming

Envelope bagging

Hot Searches