- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

7.5 kW

-

Model:

-

TY-201DD

-

Capacity:

-

2 pallets/minute

-

Working mode:

-

Manual feeding/Auto Nailing/Auto stacking

-

Operating mode:

-

Industrial LCD computer

-

Operational mode:

-

Intelligent control system

-

Max power:

-

7.5 kW

-

Feeding speed:

-

80 m/min

-

Voltage:

-

380 V, 50 Hz, 3P

-

Air compressor:

-

100 L

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Thoyu

-

Weight (KG):

-

3500 KG

-

Power (kW):

-

7.5 kW

-

Model:

-

TY-201DD

-

Capacity:

-

2 pallets/minute

-

Working mode:

-

Manual feeding/Auto Nailing/Auto stacking

-

Operating mode:

-

Industrial LCD computer

-

Operational mode:

-

Intelligent control system

-

Max power:

-

7.5 kW

-

Feeding speed:

-

80 m/min

-

Voltage:

-

380 V, 50 Hz, 3P

-

Air compressor:

-

100 L

|

Product Description

|

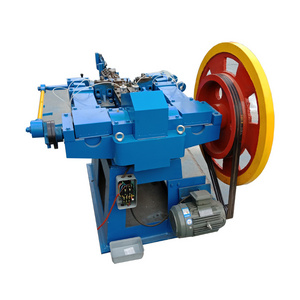

CNC pallet nailer adopts advanced CNC technology; it is suitable for CP1-CP9 pallets (all kinds of pallets, American pallets and Euro pallets). For same type different size pallet, it needs adjust the fixture; for different type pallets, it needs change the fixture.

|

Product Data

|

|

CNC Pallet Nailer |

|

|

Model |

TY-201DD |

|

Capacity |

2 pallets/minute |

|

Working mode |

Manual feeding/Auto Nailing/Auto stacking |

|

Operating mode |

Industrial LCD computer |

|

Operational mode |

Intelligent control system |

|

Motor power |

servo motor |

|

Max power |

7.5 kW |

|

Processing dimension (length, width, thickness) |

Customized |

|

Feeding speed |

80 m/min |

|

Voltage |

380 V, 50 Hz, 3P |

|

Air compressor |

100 L |

|

Workers needs |

2-3 workers |

|

Nail size |

32-90 mm |

|

Overall dimensions |

4540*5200*1985 mm |

|

Weight |

3500 kg |

|

Product Character

|

1. Adjustable Pallet Size

CNC pallet nailer is designed to produce American standard pallets, European standard pallet, and customized pallets.

2. Advanced Technology

CNC pallet nailer is equipped with the finished pallet stacking device, which has high automation degree, smooth and tight process flow, and can be equipped with automatic pallet stacking machine and one-stop nailing and stacking production.

3. Profit-Building

CNC pallet nailer adopts the fully automatic program, and the operating system adopts imported PLC control, the touch screen is simple to operate, with convenient control, and accurate nailing position. Besides, CNC pallet nailer is with multiple processes are completed at one time, which greatly improves the work efficiency.

4. Cost-Effective

Automatic nailing and stacking are connected into the whole production line. After the nailing process is completed, the finished wooden pallets are automatically flipped onto the stacking platform and stacked neatly. So that it can achieve the effect of automatic receiving, which is convenient for forklift transportation; at same time, saving the time of the nailing machine and the stacking operation. On account of the workpieces do not need to be stacked and rotated, and directly flipped into the lifting platform. It not only reduces the labor intensity, but also reduces time and space for handling.

5. More Safe

CNC pallet nailer has no specific requirements for the operator, and it is equipped with photoelectric switch, safety light curtain to ensure safe production.