- Product Details

- {{item.text}}

Quick Details

-

roll set size:

-

50*300*65

-

precessing range:

-

19mm-51mm

-

thickness:

-

0.2-1.2mm

-

forming lenght:

-

290mm

-

reduce the wedge line program:

-

200/ma

-

amount of mold opening and closing:

-

20/max

-

main motor:

-

4-6kw

-

spindle speed:

-

200/rev/min

-

spindle center heigh:

-

800

-

weight:

-

2000

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Jopar

-

Weight (KG):

-

1500

-

roll set size:

-

50*300*65

-

precessing range:

-

19mm-51mm

-

thickness:

-

0.2-1.2mm

-

forming lenght:

-

290mm

-

reduce the wedge line program:

-

200/ma

-

amount of mold opening and closing:

-

20/max

-

main motor:

-

4-6kw

-

spindle speed:

-

200/rev/min

-

spindle center heigh:

-

800

-

weight:

-

2000

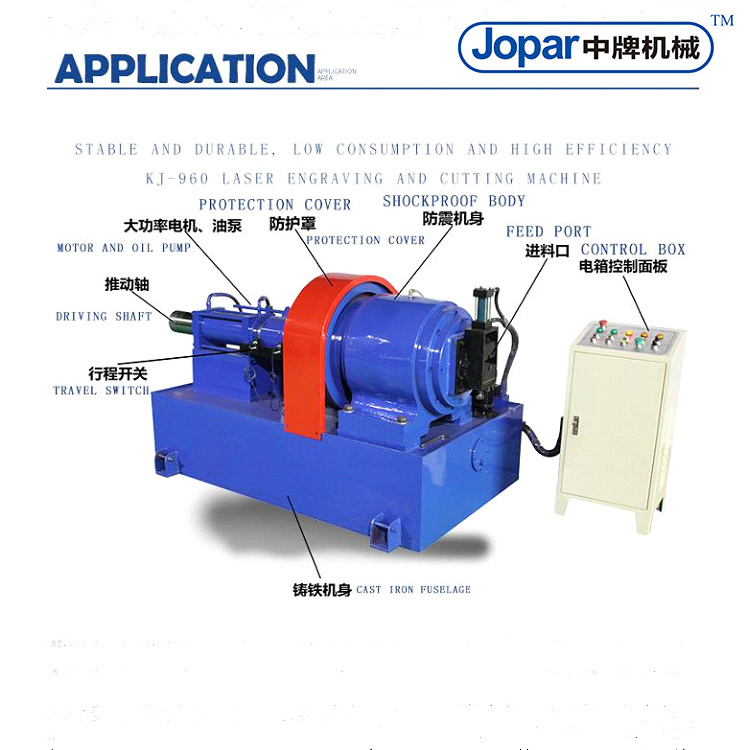

It is used to rotary the workpiece is cold forming, such bar, pipe, steel rope, ect. The raw material can be copper,

stainless steel, iron, alloy titanium, ect.

Main technical:

1 Mold size: 60*300*70

2 Working presion: +/-0.01mm

10 Overall size: 2000x1000x1500 MM

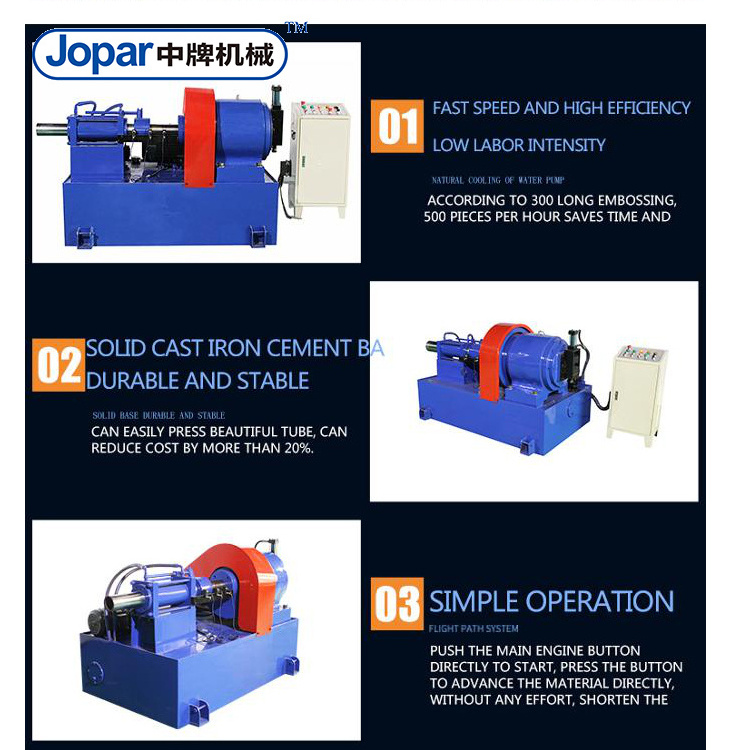

Machine Advantage

Cost-effective

High Sqeed

Low Processing

High Effciency

Feature

It's considerabluy faster than manual operation,and saving cost of human laboor.

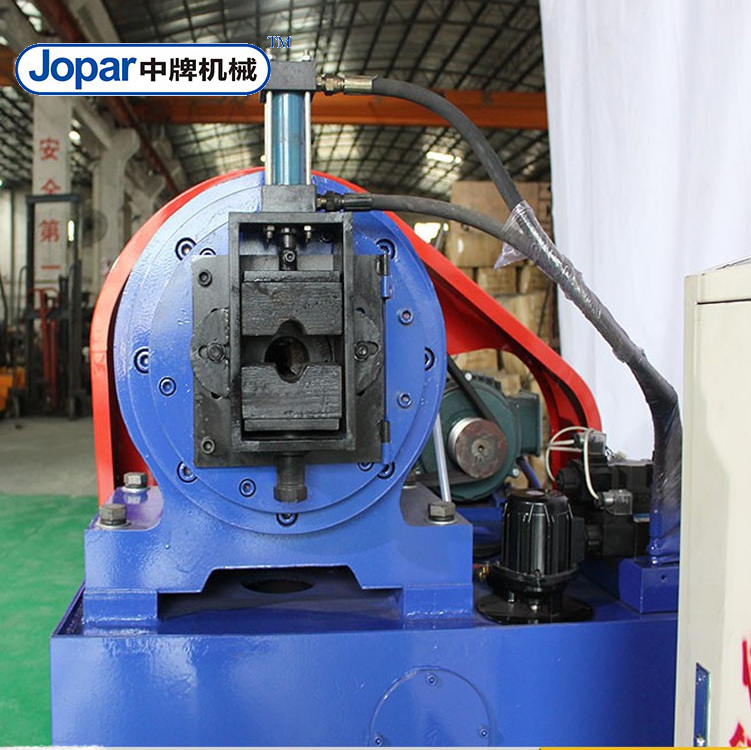

Decorative Pipe Machine Details:

1. Controller.

Button control, easy operation.

2. Hydraulic Station.

Precision flow and pressure control for different pipe.

3.Right: oil pump, left: spindle motor.

The oil pump is used to pump oil to each cylinder,

the spindle motor is driven by the main shaft.

3. Automatic locking.

Clamp the pipe during working.

4. Various Pipe Pattern Molds.

One freel mold, accept custom design pattern molds.

| One Mould For Free | 1-year warranty | OEM Service |

| One machine have one free mould | The main parts of the equipment are maintained or changed for free within one year. |

We can be customized design for you.

|