- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DINGTUO

-

Model Number:

-

DT80BLF160-3160

-

Torque:

-

1.8N.m

-

Insulation Class:

-

B

-

Duty Type:

-

S1

-

Feedback Method:

-

Hall Sensors

-

Communication Angle:

-

120°

-

Winding Connection:

-

Star

-

Dielectrical Strength:

-

500VAC/1KHz/1mA/1s

-

Motor length:

-

160mm

-

Poles:

-

2

-

Shaft Dia.:

-

14mm

-

Weight:

-

3.0kg

Quick Details

-

Speed(RPM):

-

6000RPM

-

Continuous Current(A):

-

3A

-

Efficiency:

-

IE 2

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DINGTUO

-

Model Number:

-

DT80BLF160-3160

-

Torque:

-

1.8N.m

-

Insulation Class:

-

B

-

Duty Type:

-

S1

-

Feedback Method:

-

Hall Sensors

-

Communication Angle:

-

120°

-

Winding Connection:

-

Star

-

Dielectrical Strength:

-

500VAC/1KHz/1mA/1s

-

Motor length:

-

160mm

-

Poles:

-

2

-

Shaft Dia.:

-

14mm

-

Weight:

-

3.0kg

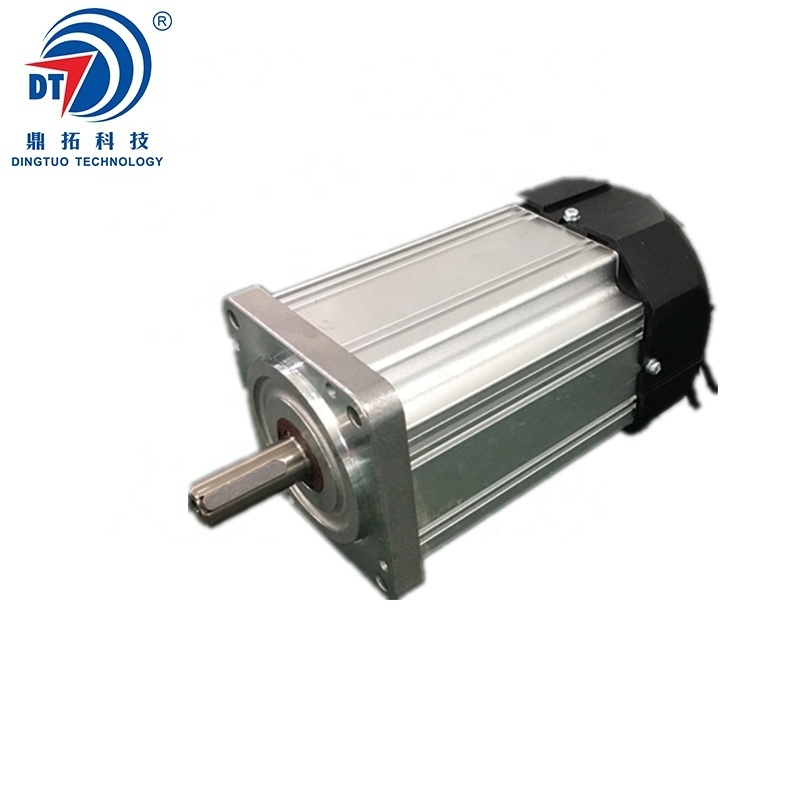

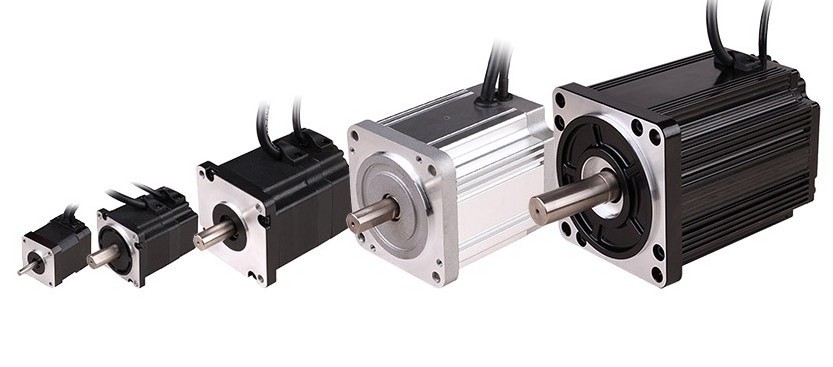

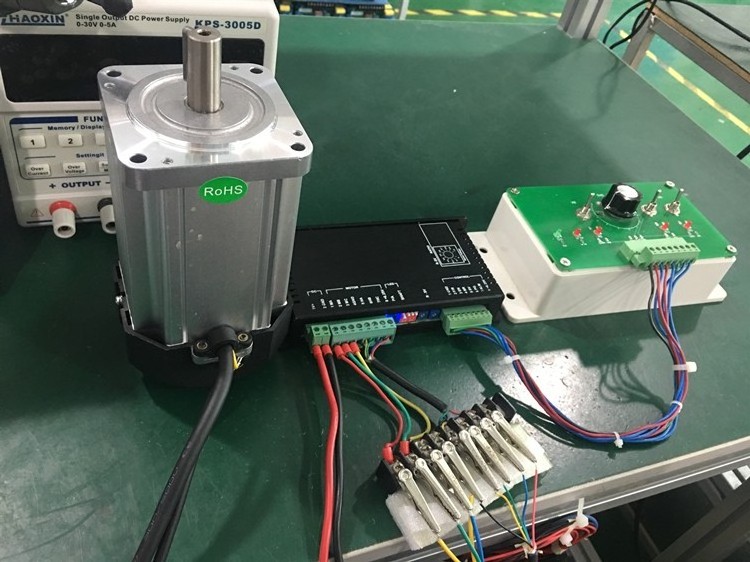

1KW Brushless motor 310V BLDC motor with hall sensors

-High reliability(no brush wear)-even at very high achievable speeds

-High efficiency

-Low EMI

-Driven by multi-phase Inverter controllers

-Sensorless speed control possible

-Advantages compared to brushed DC motors:

-Lighter

-Accelerate faster

-Produce little electrical and acoustic noise

-Require no maintenance

Motor Specifications

|

General

|

|

|

|

|||

|

Insulation Class

|

|

B

|

|

|||

|

Duty Type

|

|

S1

|

|

|||

|

Feedback Method

|

|

Hall Sensors

|

|

|||

|

Communication Angle

|

|

120°

|

|

|||

|

Winding Connection

|

|

Star

|

|

|||

|

Dielectrical Strength

|

|

500VAC / 1KHz / 1mA / 1s

|

|

|||

|

Insulation Resistance

|

|

100MΩ / 500VDC

|

|

|||

|

Performance

|

|

|

|

|

|

|||||

|

Rated Voltage

|

U

N

|

V

|

48/310

|

|

|

|||||

|

Rated Power

|

P

N

|

W

|

500/750/1100/1200/1800/2000

|

|

|

|||||

|

Rated Torque

|

T

N

|

N

·

m

|

1.2/1.8/3.0/4.0

|

|

|

|||||

|

Rated Speed

|

n

N

|

RPM

|

4000/5000/6000

|

|

|

|||||

|

Poles

|

-

|

-

|

2/4

|

|

|

|||||

|

Length

|

L

|

mm

|

140/160/180/190

|

|

|

|||||

|

Mass

|

-

|

Kg

|

1.8/3.0/3.5/4.0

|

|

|

|||||

|

Item

|

Rated Power

W

|

Rated Voltage

VDC

|

Rated Speed

RPM

|

Rated Torque

RPM

|

Length

mm

|

Weight

Kg

|

|

DT80BLF140-460

|

750

|

48

|

6000

|

1.2

|

140

|

1.8

|

|

DT80BLF140-3140

|

500

|

310

|

4000

|

1.2

|

140

|

1.8

|

|

DT80BLF140-3160

|

750

|

310

|

6000

|

1.2

|

140

|

1.8

|

|

DT80BLF160-3140

|

750

|

310

|

4000

|

1.8

|

160

|

3.0

|

|

DT80BLF160-3160

|

1100

|

310

|

6000

|

1.8

|

160

|

3.0

|

|

DT80BLF180-3140

|

1200

|

310

|

4000

|

3.0

|

180

|

3.5

|

|

DT80BLF180-3160

|

1800

|

310

|

6000

|

3.0

|

180

|

3.5

|

|

DT80BLF190-3150

|

2000

|

310

|

5000

|

4.0

|

190

|

4.0

|

Dimensional Drawings

Today, a growing number of applications rely on a brushless DC (BLDC) motor, ranging from automotive to industrial applications. Moreover, BLDC motors are used in medical equipment, home appliances, building controls and industrial automation. In each instance, a BLDC motor is chosen for the numerous advantages it offers, including:

▲Highest efficiency

▲Small motor size

▲Light weight

▲Longer lifetime

▲No maintenance

▲No sparking

▲Steady operation

▲Variable speed

As CE, ROHS, National Hi-tech Enterprise certified quality company, we strictly abide by Quality Control System, pursuing continuous improvement of products quality.

CE Declaration

DINGTUO' assures that our drives & motors meet the European Norm Standard.

RoHS Compliant

DINGTUO' is committed to offering products compliant with the EU RoHS directive.

National Hi-tech Enterprise

DINGTUO continues to carry out research and development and transformation of technological achievements in the "High-tech Fields Supported by the State", and forms core intellectual property rights of the enterprise, and conducts business activities based on this.

Computer Software Copyright Registration

DINGTUO obtained the computer software copyright registration certificate issued by the Copyright Bureau to realize the protection of computer software developed independently.

Customer satisfaction is DINGTUO's primary aim, our drives and motors are designed to your exact specifications and we choose the right materials for client's samples.

Who we are

Shenzhen Dingtuoda Electromechanics Co.,Ltd(DINGTUO TECHNOLOGY)

was established in 2006. As a professional electric motor and driver manufacturer operating over 13 years, DINGTUO is first and foremost a reflection of its people.

Our company focus on

professional R & D, production and sales of Servo/Stepper/BLDC motor system

. We also committed to provide

Customized OEM & ODM

services to Global electrical distributors, industrial equipment manufacturers and automotive markets.

DINGTUO manufacturing center covering area around 2,500 M², and owning three production workshops, 9 production lines.

We are also continuously improving the performance and power efficiency of our products to help our customers enable new markets and applications.

Technology & Innovation

Manufacturing

Quality and delivery are the most important aspects of DINGTUO Motor Driver's manufacturing processes. DINGTUO prides itself on offering the highest quality products with the best possible delivery times. It all begins with DINGTUO's manufacturing process. DINGTUO manufactures all of its products under strict quality standards at plants within Guangdong China.

Quality is Built-In

DINGTUO operates in a Just-in-time and a Lean Manufacturing environment. Quality is built-in to the product throughout the entire manufacturing process. This is achieved by utilizing the One-Piece Flow System on our Flexible U-line work cells wherein all necessary equipment are positioned in the sequence in which it is used. In the simplest of terms, one-piece flow means that each motor is carefully built one-piece-at-a-time allowing it to be thoroughly inspected and tested, thus, quality defects are easily detected and contained.

Additionally, defect prevention is also the direct result of the continuous error proofing of our processes.

Product Testing

Every DINGTUO product undergoes reliability testing before they are released to the market. These test subject the product to the harshest of operating conditions and intentional misuse to discover the limits of their durability.

1 Year Warranty

DINGTUO stands behind every product with a 1 Year Warranty. Visit our warranty section for complete details.

Production Line

As the years of development, Now DINGTUO Technology has become the leader of motor control systems provider, It own production lines:

-Stepper Drives & Motors

-Servo Drives & Motors

-Brushless DC Drives & Motors

-Integrated Motors

-Linear Motion Systems

Advantage of DINGTUO TECHNOLOGY

-National High-tech enterprise certification

-Motor Drives Innovative &production team Over 13 years

-Electric Motor & Drives production workshop

-Strict quality management system

-Professional one stop supply & service

-OEM & ODM available

-Reliable and timely customer service

Trade Show