- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

LS 10.14

-

Name:

-

Hydraulic Bending Machine Sheet Metal Forming Dies Press Brake Tooling

-

Material:

-

42CrMo

-

Size:

-

Standard Customize

-

HRC:

-

47°±2°

-

Supply Ability:

-

500 Pieces/Month

-

Precision Level:

-

Very High

-

Delivery Time:

-

20-35 days

-

Package:

-

Wooden Box

-

Insurance:

-

Included

-

OEM:

-

Available

Quick Details

-

Shaping Mode:

-

Forging Mould

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Lynccn

-

Model Number:

-

LS 10.14

-

Name:

-

Hydraulic Bending Machine Sheet Metal Forming Dies Press Brake Tooling

-

Material:

-

42CrMo

-

Size:

-

Standard Customize

-

HRC:

-

47°±2°

-

Supply Ability:

-

500 Pieces/Month

-

Precision Level:

-

Very High

-

Delivery Time:

-

20-35 days

-

Package:

-

Wooden Box

-

Insurance:

-

Included

-

OEM:

-

Available

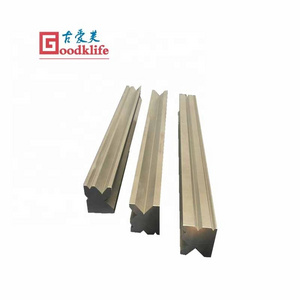

Product Description

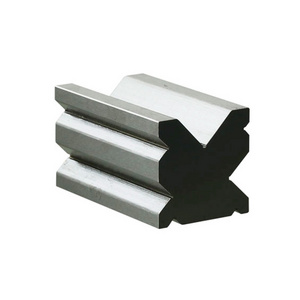

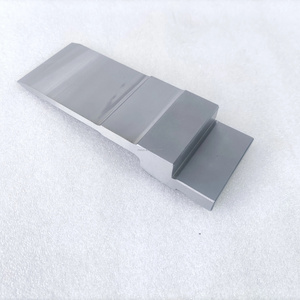

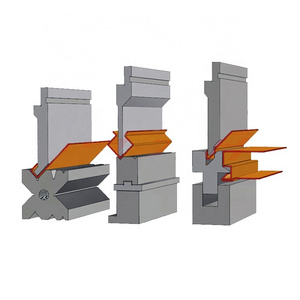

Press brake tool

.

It is a tool used by the bending machine to form and process sheet metal. This tool consists of various parts, and different molds consist of different parts. It mainly realizes the processing of the shape of the article by changing the physical state of the formed material. A tool used to make a blank into a specific shape and size under the pressure of a bending machine.

|

Product Name

|

Press Brake Tooling

|

|

Material

|

42CrMo

|

|

Color

|

Metallic

|

|

Size

|

Customizable sizes

|

|

Hardness

|

45-50HRC

|

|

Precision Level

|

Very High

|

|

Standard

|

AMADA, European, Segmented, Arc, International Standard, Three Point, Non-Streaking, Adjustable Groove, Special, etc

|

|

Application

|

Used on press brake machine

|

|

Package

|

Wooden crate with soft film layers inside

|

|

Certification

|

ISO9001

|

Support customization, please let us know your requirements

1. Material

2. Forging

2. Forging

3. a. Miller Processing(if your products are small)

b. Planer Processing(if your products are large)

4. Precisional Grinder Processing

5. Finished Products

6. Measuring

7. Packing: Wooden crate with soft film layers inside

8. Delivery Details: Shipped in 20 days after payment

b. Planer Processing(if your products are large)

4. Precisional Grinder Processing

5. Finished Products

6. Measuring

7. Packing: Wooden crate with soft film layers inside

8. Delivery Details: Shipped in 20 days after payment

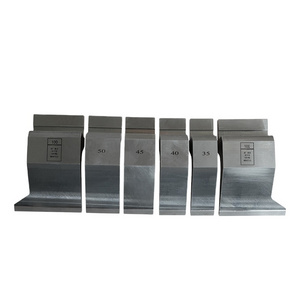

Products Show

Standard mould

1. When ordering a standard mold, first select the shape of the mold.

1. When ordering a standard mold, first select the shape of the mold.

2. Provide the total length, angle, sharp R, die height, etc

3. The mold that needs to be divided can be divided into dimensions

Special forming mould

1. Provide the cross section shape drawing of product workpiece

2. Provide bending machine manufacturer, machine tonnage, machine length and other relevant data.

3. Provide product material, plate thickness and other data.

4. Put forward product requirements (such as scratch, R angle size, parallelism, straightness)

5. Provide product materials (for mold test)

6. If there is any difficulty in selecting the mould, please consult us.

3. The mold that needs to be divided can be divided into dimensions

Special forming mould

1. Provide the cross section shape drawing of product workpiece

2. Provide bending machine manufacturer, machine tonnage, machine length and other relevant data.

3. Provide product material, plate thickness and other data.

4. Put forward product requirements (such as scratch, R angle size, parallelism, straightness)

5. Provide product materials (for mold test)

6. If there is any difficulty in selecting the mould, please consult us.

Our Company

Product Categories

Exhibition & Certificate

Packaging

FAQ

Yes we can, but only for products length less than 1000mm.

2. When can you ship the products after we make payment?

Production time is normally 10-25 days. We will deliver your products to port in 2 days

3. What is the Minimum Order Quantity (MOQ) for your OEM service?

MOQ:1pcs

4. How can you guarantee the quality?

We are the only constitutor of Chinese National Press Brake Mold Industry Standard. We will offer you 3 months guarantee once you purchase from us. We have IQNET Certificate.

5. Is it possible to visit your company? How can I get there?

We would love to have you. We can send you invitation for VISA application and we will collect you in Nanjing Airport or Railway station.

Hot Searches