- Product Details

- {{item.text}}

Quick Details

-

Productivity:

-

12M³/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yugong

-

Weight:

-

500 kg

-

Dimension(L*W*H):

-

6200*2050*2200 mm

-

Product Name:

-

Trailer Concrete Pump

-

Capacity:

-

30m3/h

-

Feeding Height:

-

0.7m

-

Max.Aggregate Size:

-

20mm

-

Working Principle:

-

S Pipe Valve

-

Feature:

-

Electric Concrete Pump

-

Ver. Conveying Distance:

-

20m

-

Hor. Conveying Distance:

-

50m

-

Conveying Pipe Diameter:

-

65mm-80mm

-

Electric Power:

-

90kw

Quick Details

-

Power Type:

-

Electric

-

Max. vertical conveying distance:

-

60M

-

Max. horizontal conveying distance:

-

180M

-

Productivity:

-

12M³/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yugong

-

Weight:

-

500 kg

-

Dimension(L*W*H):

-

6200*2050*2200 mm

-

Product Name:

-

Trailer Concrete Pump

-

Capacity:

-

30m3/h

-

Feeding Height:

-

0.7m

-

Max.Aggregate Size:

-

20mm

-

Working Principle:

-

S Pipe Valve

-

Feature:

-

Electric Concrete Pump

-

Ver. Conveying Distance:

-

20m

-

Hor. Conveying Distance:

-

50m

-

Conveying Pipe Diameter:

-

65mm-80mm

-

Electric Power:

-

90kw

Product Show

1.The special pouring pump for secondary structure fine stone mortar can realize the transportation of fine stone concrete and mortar for long-distance high-rise buildings.

2.The distribution valve adopts advanced S-tube valve, which has good sealing performance and simple and reliable structure.

3.The eye plate (commonly known as wear plate) and floating cutting ring are made of hard alloy, which has good wear resistance, long service life and convenient replacement. The cutting ring can automatically compensate the gap structure.

4.The machine adopts electric-liquid control mode, with perfect electro-hydraulic overload protection and instrument display system. It has anti-pump operation function, easy to eliminate blockage fault. The pumping speed can be adjusted to meet various working conditions.

5.The centralized lubrication system automatically controls the start and stop and running time by the program, effectively

extending the service life of the rotating parts.

6.The electrical components such as the contactor and the push button switch are reliable in operation, the control circuit is simple, and the electrical box is equipped with a switch for easy operation.

7.The main seals are made of high quality seals to prevent internal and external leakage of the hydraulic system.

2.The distribution valve adopts advanced S-tube valve, which has good sealing performance and simple and reliable structure.

3.The eye plate (commonly known as wear plate) and floating cutting ring are made of hard alloy, which has good wear resistance, long service life and convenient replacement. The cutting ring can automatically compensate the gap structure.

4.The machine adopts electric-liquid control mode, with perfect electro-hydraulic overload protection and instrument display system. It has anti-pump operation function, easy to eliminate blockage fault. The pumping speed can be adjusted to meet various working conditions.

5.The centralized lubrication system automatically controls the start and stop and running time by the program, effectively

extending the service life of the rotating parts.

6.The electrical components such as the contactor and the push button switch are reliable in operation, the control circuit is simple, and the electrical box is equipped with a switch for easy operation.

7.The main seals are made of high quality seals to prevent internal and external leakage of the hydraulic system.

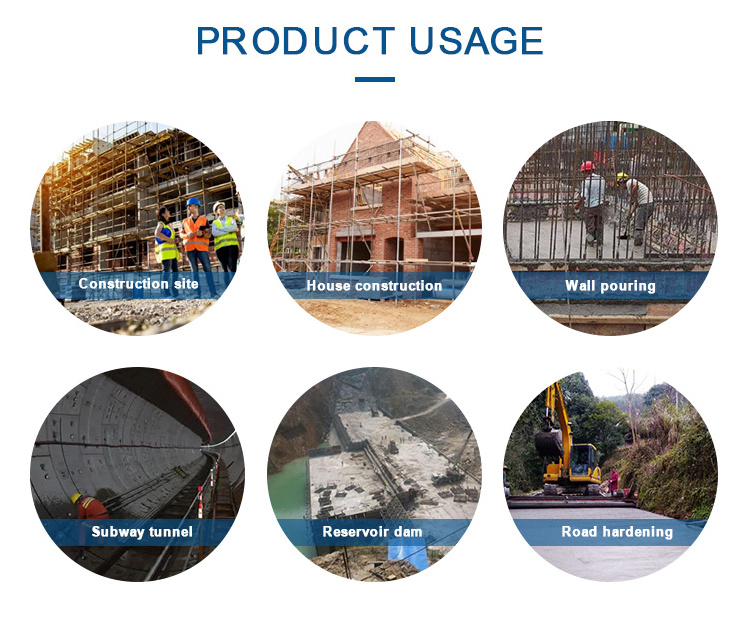

Product Application

Specification

Details

Power system:

1. Using KOREA KAWASAKI brand of Oil pump

2. Using well-known motor (30KW) from China.

Main pumping system:

1.Using Master Cylinder of HUNAN XIELI and Concrete Cylinder of WUXI ZHONGHONG. hydraulic grout pump

2. Open-loop hydraulic circuit.

Mixing system:

1. Using cycloid motor from Gold supplier in China..

2. Using super-resistant mixing blade shaft with pedal-style.

3. The hardness of left and right axle HB250-280 after quenched treatment. The thickness of the surface nitride is more than 0.3mm, and the surface hardness is more than HB550. hydraulic grout pump

Cooling and filtration devices:

1. Using oil filter from WENZHOU LEEMIN that Zoomlion used. The filtration accuracy of main pump suction filter is 10.

2. Coolers from airline products are of reliable quality and good heat dissipation.hydraulic grout pump

Hydraulic piping and valve:

1. Using imported Italian MANULI oil pipe.

2. Using hydraulic control valve from the China HUADE company.

Electronic control systems:

1. Using AC contractors and control buttons from China famous brand.

2. Using Intermediate relay from JAPAN Omron.

3. Using GSK proximity switches from Germany.

1. Using KOREA KAWASAKI brand of Oil pump

2. Using well-known motor (30KW) from China.

Main pumping system:

1.Using Master Cylinder of HUNAN XIELI and Concrete Cylinder of WUXI ZHONGHONG. hydraulic grout pump

2. Open-loop hydraulic circuit.

Mixing system:

1. Using cycloid motor from Gold supplier in China..

2. Using super-resistant mixing blade shaft with pedal-style.

3. The hardness of left and right axle HB250-280 after quenched treatment. The thickness of the surface nitride is more than 0.3mm, and the surface hardness is more than HB550. hydraulic grout pump

Cooling and filtration devices:

1. Using oil filter from WENZHOU LEEMIN that Zoomlion used. The filtration accuracy of main pump suction filter is 10.

2. Coolers from airline products are of reliable quality and good heat dissipation.hydraulic grout pump

Hydraulic piping and valve:

1. Using imported Italian MANULI oil pipe.

2. Using hydraulic control valve from the China HUADE company.

Electronic control systems:

1. Using AC contractors and control buttons from China famous brand.

2. Using Intermediate relay from JAPAN Omron.

3. Using GSK proximity switches from Germany.

Other related products

Hot Searches