- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

LSTD

-

Model Number:

-

LSTD

-

Usage:

-

Polishing, lapping or polishing

-

Feature:

-

long period

-

Application:

-

Polishing Metal

-

Advantage:

-

stable

-

Size:

-

3.1-38

Quick Details

-

Type:

-

Polishing Slurry

-

Abrasive Grain Sizes:

-

0.05

-

Warranty:

-

1 year

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

LSTD

-

Model Number:

-

LSTD

-

Usage:

-

Polishing, lapping or polishing

-

Feature:

-

long period

-

Application:

-

Polishing Metal

-

Advantage:

-

stable

-

Size:

-

3.1-38

Product Description

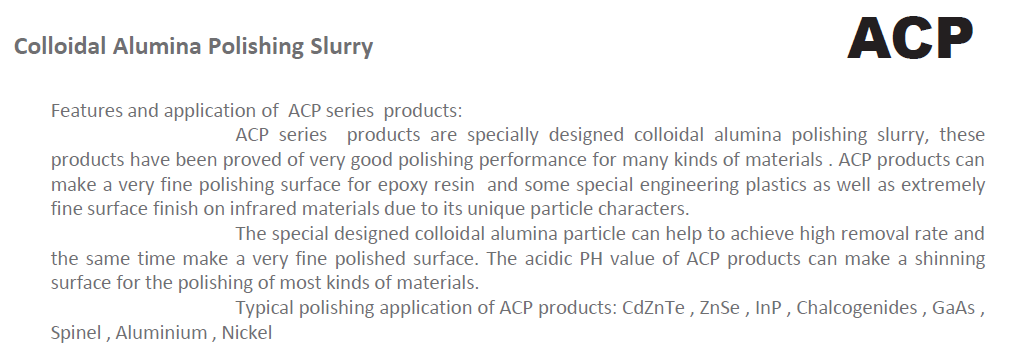

Lapping/Polishing Slurry

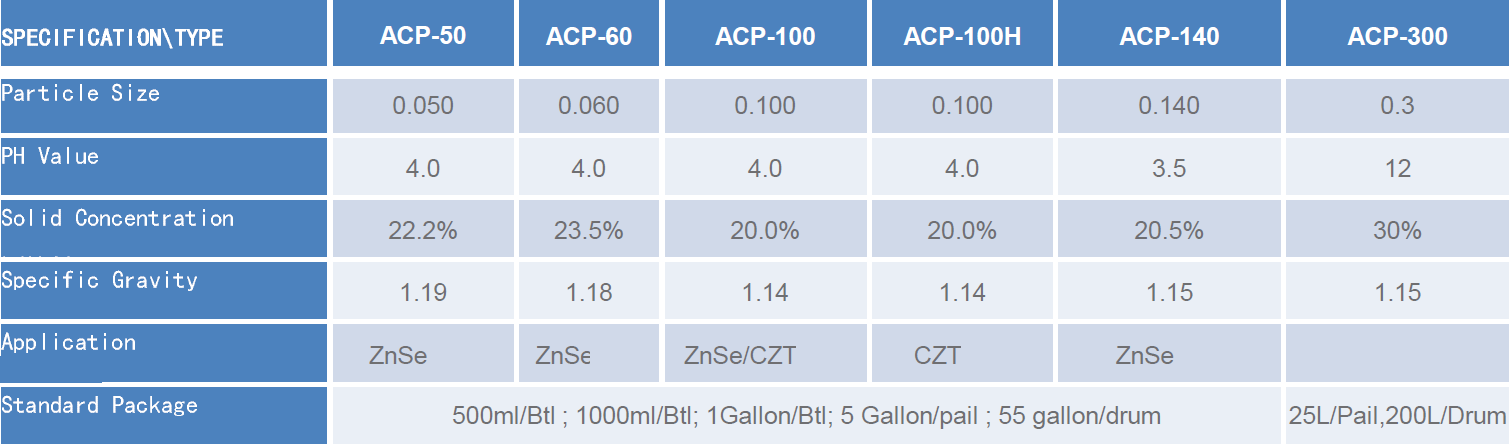

Colloidal Alumina Polishing Slurry

Related Products

Company Introduction

Shanghai Leading Semicongductor Technology

Development Co., Ltd.

Shanghai Leading Semicongductor Technology Development Co., Ltd. is a comprehensive solution to the professional supplier of precision plane processing scheme, the precision plane grinding, polishing and grinding applications for customers on behalf of the world's most advanced level and the highest quality equipment, supplies and technology service.

The leaders, including their own laboratories, factories and technicians, can engage in the design, manufacture, polishing and polishing processing services of the open developing and non-standard polishing equipments.

-WORKSHOP-

-EXHIBTION-

Certifications

Subcontractor Service

Based on our strong technical background and know-how, the same time, equipped with necessary machines including small sized and big sized grinding, lapping and polishing machines,

we are able to provide lapping and polishing subcontractor service for our customers

from small quantity of sample preparation to mass production.

As a professional supplier of lapping/polishing machines, consumables and processes, LSTD has the ex-tremely strong advantage supplying the subcontractor service in terms of manufacturing cost, efficiency and quality control.

-MACHINE MODIFICATION & CUSTOMIZE BUILDING-

Specialized in the lapping/polishing industry plus a very strong mechanical and electrical designing ability, we are able to customize any types of lapping and polishing machines. Different from standard machines, customized machines can match well the actual needs of customers.

By the using of auto loading and unloading system, the manufacturing efficiency can be greatly improved and the same time, the manufacturing cost is much lower.

Contact Way

Hot Searches