- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Huamo

-

Material:

-

Wooden package with film

-

Weight (KG):

-

4 kg

-

Product name:

-

Conductively meter

-

Application:

-

Water Treatment

-

Dehydration treatment type:

-

screw pusher extrusion type

-

Absolutely dry mud processing capacity:

-

6-10 Kgh

-

Equipment size:

-

L1970*W800*H1170

-

Machine weight:

-

190kg

-

Total power:

-

0.77kw

-

Sewage inlet:

-

DN50 inner wire (SS304)

-

Dosing port:

-

DN20 pipe interface (UPVC, 1.0mpa)

-

Certification:

-

CE

Quick Details

-

Applicable Industries:

-

Water Treatment

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Huamo

-

Material:

-

Wooden package with film

-

Weight (KG):

-

4 kg

-

Product name:

-

Conductively meter

-

Application:

-

Water Treatment

-

Dehydration treatment type:

-

screw pusher extrusion type

-

Absolutely dry mud processing capacity:

-

6-10 Kgh

-

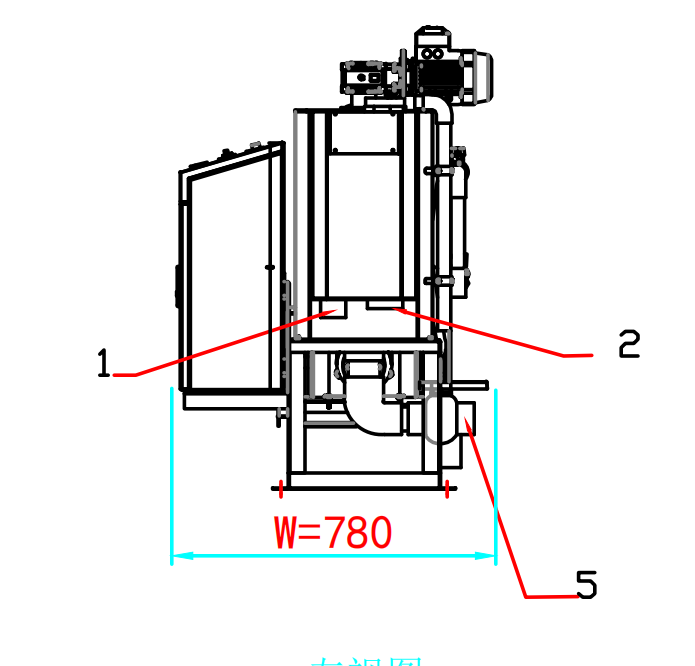

Equipment size:

-

L1970*W800*H1170

-

Machine weight:

-

190kg

-

Total power:

-

0.77kw

-

Sewage inlet:

-

DN50 inner wire (SS304)

-

Dosing port:

-

DN20 pipe interface (UPVC, 1.0mpa)

-

Certification:

-

CE

Product Description

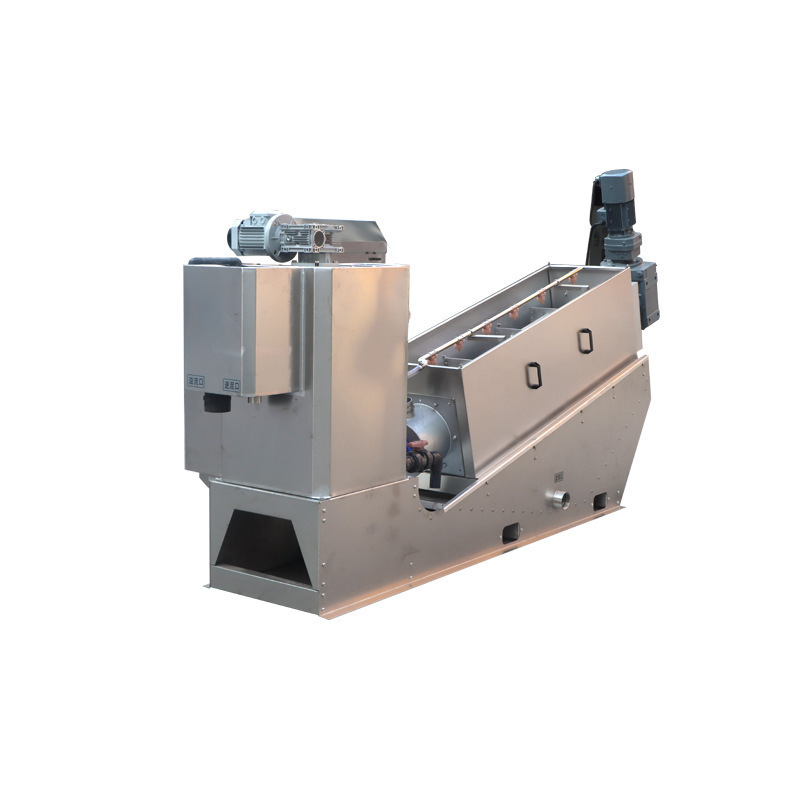

1.Spiral sludge dewatering machine

2.Screw sludge dewatering machine

Controls the dehydrator host, flocculant stirring device, solenoid valve, frequency conversion reversal, thermal overload protection, delayed operation, scheduled cleaning and other functions; realizes automatic operation and manual operation of the dehydrator.

Manufacturer Sludge Dewatering Treatment Machine Automatic Solid-liquid Separation Screw Press Sludge Thickening Machine

|

Technic Datasheet

|

|

|

||

|

Device Name:

|

Spiral sludge dewatering machine/ Screw sludge dewatering machine

|

|

||

|

Model

|

DL-101

|

|

||

|

Dehydration treatment type

|

screw pusher extrusion type

|

|

||

|

Absolutely dry mud processing capacity

|

6-10 Kg∕h

|

|

||

|

Dimension

|

L=1970*W=800*H=1170mm

|

|

||

|

Weight

|

≈190kg

|

|

||

|

Total power

|

0.77kw

|

|

||

|

Main equipment configuration

|

Item

|

Parameters

|

||

|

Flocculation mixing box

|

Quantity

|

1 set

|

||

|

|

Material

|

SS304

|

||

|

|

Sewage inlet

|

DN50 inner wire (SS304)

|

||

|

|

Overflow mouth

|

DN65 inner wire(SS304)

|

||

|

|

Dosing port

|

DN20 Pipe interface(UPVC,1.0mpa)

|

||

|

|

Vent

|

DN50 Ball Valve(UPVC,1.0mpa)

|

||

|

Main body of snail stack

|

Diameter×Length

|

Φ130x1150mm

|

||

|

|

Quantity

|

1 Group

|

||

|

|

Material

|

SS304

|

||

|

|

Support plate

|

Material:SS304

|

||

|

|

Control way

|

Each group of screw stacking bodies can be started or stopped independently.

|

||

|

|

Assembly type

|

The segmented design of the main body facilitates later maintenance, and the double-layer design of the support plate ensures

stable operation of the equipment. |

||

|

Spiral shaft

|

Quantity

|

1 pc

|

||

|

|

Material

|

SS304

|

||

|

|

Treatment craft

|

After welding, the whole body is finished and the blades are sprayed with tungsten carbide supersonic spray.

|

||

|

|

Hardness

|

1100HV

|

||

|

Sump

|

Material

|

SS304

|

||

|

|

Filtrate outlet

|

DN80 inner wire(SS304)

|

||

|

Motor

|

Power

|

0.4kw

|

||

|

|

Voltage level

|

380V,50HZ

|

||

|

|

Protection level

|

IP55

|

||

|

|

Insulation level

|

F

|

||

|

|

Quantity

|

1 pc

|

||

|

|

Rotating speed

|

2.5-3.4r/min

|

||

|

|

Brand

|

China brand

|

||

|

Stirring motor

|

Power

|

0.37kw

|

||

|

|

Insulation level

|

F级

|

||

|

|

Quantity

|

1 pc

|

||

|

|

Rotating speed

|

25r/min

|

||

|

|

Brand

|

China Brand

|

||

|

Flushing device

|

Type

|

conical water column

|

||

|

Rinse water inlet

|

Pressure

|

0.2MPa

|

||

|

|

Rinse water inlet

|

DN20 Pipe interface(UPVC,1.0mpa)

|

||

|

|

Nozzle

|

Quantity:4pcs

|

||

|

|

Spray pipe

|

Size:DN20

|

||

|

The electromagnetic valve

|

Pipe diameter

|

DN20

|

||

|

|

Quantity

|

1pc

|

||

|

|

Material

|

Reinforced polypropylene

|

||

|

|

Protection level

|

IP65

|

||

|

|

Brand

|

China brand

|

||

|

Electrical control cabinet

|

Size

|

500mmx600mmx250mm

|

||

|

|

Material

|

Carbon steel spray

|

||

|

|

Protection level

|

IP55

|

||

|

|

Control circuit

|

AC 220V

|

||

|

|

Component brand

|

Zhengtai

|

||

|

|

Inverter brand

|

Zhongchen, Shanghai

|

||

|

|

Function

|

Controls the dehydrator host, flocculant stirring device, solenoid valve, frequency conversion reversal, thermal overload

protection, delayed operation, scheduled cleaning and other functions; realizes automatic operation and manual operation of the dehydrator. |

||

Specification

Certification

Hot Searches