1. Tank depth H <3m

2. Direction can be adjusted in horizontal and vertical

3. Depth of guide rod is 3 meters

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

100kg

-

Size:

-

2.3

-

Power:

-

0.37-22

-

Weight (KG):

-

200 kg

-

Product name:

-

Submersible Mixer

-

Application:

-

Wastewater Treatment Plant

-

Function:

-

Circulation

-

Features:

-

Eco-Friendly Easy Operation

-

Certification:

-

ISO9001

-

Package:

-

Plywood Package

-

Type:

-

Submeisible Type

-

Technology:

-

High Frequency Welding & Robot Operation

-

After-sales Service Provided:

-

After-sales Service Provided

-

Advantage:

-

24 Hours Automatic Running

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

LK

-

Material:

-

Plywooden box and plastic film

-

Weight:

-

100kg

-

Size:

-

2.3

-

Power:

-

0.37-22

-

Weight (KG):

-

200 kg

-

Product name:

-

Submersible Mixer

-

Application:

-

Wastewater Treatment Plant

-

Function:

-

Circulation

-

Features:

-

Eco-Friendly Easy Operation

-

Certification:

-

ISO9001

-

Package:

-

Plywood Package

-

Type:

-

Submeisible Type

-

Technology:

-

High Frequency Welding & Robot Operation

-

After-sales Service Provided:

-

After-sales Service Provided

-

Advantage:

-

24 Hours Automatic Running

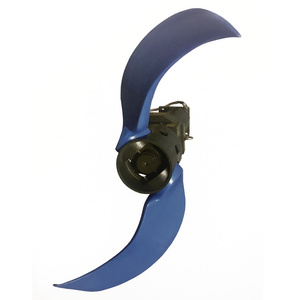

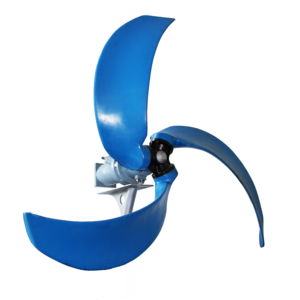

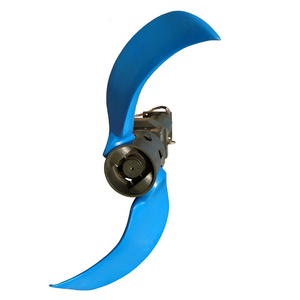

Product Overview

LK-

Submersible mixer water treatment plant pumps

LK-QJB

High quality

submisble mixers price

is used for municipal sewage treatment plant and industrial wastewater treatment plant to produce low tangential flow with force, also can be used for create a flow for circulation, nitrification, denitrification and phosphorus removing.

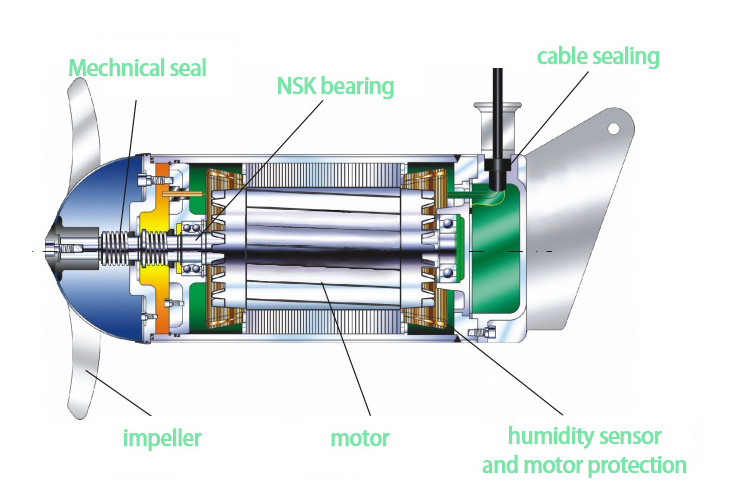

FEATURES AT A GLANCE

1. Compact structure, light weight, easy to operate and maintenance, simple installation; 2. Self-cleaning blade, preventing debris from twining or blocking;

3. Lower energy consumption,high aeration rate preventing sedimentation;

4. Two rows of independent mechanical seal, longer service life;

5. Class F insulation of motor winding, motor protection grade IP68, imported permanent -lubricated maintenance-free bearings, chamber leakage detection, motor winding overheating protection.

3. Lower energy consumption,high aeration rate preventing sedimentation;

4. Two rows of independent mechanical seal, longer service life;

5. Class F insulation of motor winding, motor protection grade IP68, imported permanent -lubricated maintenance-free bearings, chamber leakage detection, motor winding overheating protection.

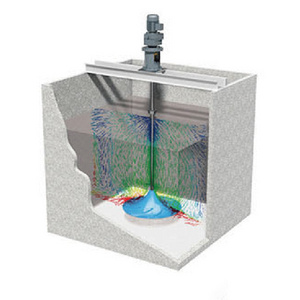

Working Conditions

* Liquid temperature: ≤ 40℃

* PH:5~9

* Liquid density:≤1150kg/m3

* Max working depth: 20m

* Motor : IP 68 , 7/24 Continuous working

* Motor MUST diving in water while operating

* PH:5~9

* Liquid density:≤1150kg/m3

* Max working depth: 20m

* Motor : IP 68 , 7/24 Continuous working

* Motor MUST diving in water while operating

Side elevation

Front elevation

Stock shop

PRODUCT SPECIFICATIONS

|

LK-QJB Submersible Mixer

|

|

|

|

|

|

|

||||||

|

Model

|

Power(KW)

|

Current(A)

|

Impeller(mm)

|

Speed(r/min)

|

Weight(kg)

|

Thrust(N)

|

||||||

|

QJB0.37/6-220/3-960/S

|

0.37

|

1.3

|

220

|

960

|

45

|

138

|

||||||

|

QJB0.55/4-220/3-1480/S

|

0.55

|

1.6

|

220

|

1480

|

45

|

145

|

||||||

|

QJB0.85/8-260/3-740/S

|

0.85

|

4

|

260

|

740

|

55

|

180

|

||||||

|

QJB1.5/6 260/3-960/S

|

1.5

|

4

|

260

|

960

|

55

|

260

|

||||||

|

QJB2.2/8-320/3-740/S

|

2.2

|

8

|

320

|

740

|

110

|

580

|

||||||

|

QJB4/6-320/3-960/S

|

4

|

12

|

320

|

960

|

115

|

690

|

||||||

|

QJB1.5/8-400/3-740/S

|

1.2

|

5.8

|

400

|

740

|

100

|

600

|

||||||

|

QJB2.5/8- 400/3-740/S

|

2.5

|

9

|

400

|

740

|

100

|

800

|

||||||

|

QJB3/8-400/3-740/S

|

3

|

11

|

400

|

740

|

100

|

920

|

||||||

|

QJB4/6-400/3-960/S

|

4

|

12

|

400

|

960

|

100

|

1200

|

||||||

|

QJB4/12-620/3-480/S

|

4

|

14.2

|

620

|

480

|

184

|

1400

|

||||||

|

QJB5/12-620/3-480/S

|

5

|

18.2

|

620

|

480

|

184

|

1800

|

||||||

|

QJB7.5/12-620/3-480/S

|

7.5

|

28

|

620

|

480

|

229

|

2600

|

||||||

|

QJB10/12-620/3 480/S

|

10

|

32

|

620

|

480

|

229

|

3300

|

||||||

|

QJB15/12-620/3-480/S

|

15

|

43

|

620

|

480

|

260

|

4000

|

||||||

|

QJB18.5/12-620/3-480/S

|

18.5

|

51

|

620

|

480

|

276

|

4400

|

||||||

|

QJB22/12-620/3-480/S

|

22

|

60

|

620

|

480

|

290

|

5300

|

||||||

Installation Instructions

Installation Ⅰ

Title goes here.

1. When depth> 4m, need add another side spport on guide rod.

2. The connection shall be expansion bolt between side support & tank wall, holder & tank bottom.

3. Please inform tank depth when you put order to us.

2. The connection shall be expansion bolt between side support & tank wall, holder & tank bottom.

3. Please inform tank depth when you put order to us.

Installation Ⅲ

1. When depth> 4m, need add another side spport on guide rod.

2. The connection shall be expansion bolt between side support & tank wall, holder & tank bottom.

3. Please inform tank depth when you put order to us.

2. The connection shall be expansion bolt between side support & tank wall, holder & tank bottom.

3. Please inform tank depth when you put order to us.

Customer Photos

FAQ

Q1: W

hat's your advantage?

A1: 1.

We have our own factory with sufficient stock, we can provide the high quality product and competitive price. 2.Our blade cutting and welding are all done by fully intelligent robotic arms, which prolongs the service life of the equipment. 3. We have own engineers' team, we can recommend the suitable scheme according to your requirements.

Hot Searches