Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1year for complete set, 1 Year

-

Brand Name:

-

WP

-

Model Number:

-

XS

-

Place of Origin:

-

Jiangsu, China

-

Horsepower:

-

2448hp

-

Cable Length:

-

10m

-

Outlet Size:

-

900MM

-

Power:

-

1800kw

-

motor:

-

1800kw

-

Product name:

-

Split case pump

-

Feature:

-

Energy Saving

-

Usage:

-

Liquid Transfer

-

Flow rate:

-

Max 11600M3/h

-

Speed:

-

2900rpm

-

Material:

-

Cast Iron,ductile iron,stainless steel

-

Fuel:

-

AC Electric Induction Motor

-

Motor:

-

380/440V

Quick Details

-

Application:

-

Commercial Buildings, Developing World Water Solutions, District Energy, Drinking water treatment, HVAC OEM, Irrigation and Agriculture, Raw Water Intake, Washing and Cleaning, Water Distribution, Water Treatment Solutions

-

Pressure:

-

Low Pressure

-

Voltage:

-

380V/440

-

Warranty:

-

1year for complete set, 1 Year

-

Brand Name:

-

WP

-

Model Number:

-

XS

-

Place of Origin:

-

Jiangsu, China

-

Horsepower:

-

2448hp

-

Cable Length:

-

10m

-

Outlet Size:

-

900MM

-

Power:

-

1800kw

-

motor:

-

1800kw

-

Product name:

-

Split case pump

-

Feature:

-

Energy Saving

-

Usage:

-

Liquid Transfer

-

Flow rate:

-

Max 11600M3/h

-

Speed:

-

2900rpm

-

Material:

-

Cast Iron,ductile iron,stainless steel

-

Fuel:

-

AC Electric Induction Motor

-

Motor:

-

380/440V

Products Description

Product introduction

Tpye XS pumps are new type of single stage double suction centrifugal split pumps with high pefformance.They are widely used inv

delivering liquids to the water plant,circulation water system of airconditioner,pipe net syetem of supplying heated

water,construction,drainage pumping station,power station,industrial water supply system,ship industry,mine and etc.

Type

XS pumps

are advanced products developed from type SH. S . SA . SLA. SAP pumps

Advange

Technical Advantage

1.Type XS pumps work stably with less noise and vibration and can work at a lifting speed due to.Short support at both sides, thus

they can be widely used.

2.The pipelines arrangement of type XS pump looks simple and beautiful due to inlet and outlet at a same center line.

3.The same rotor of type XS pumps can be operated at reverse direction to avoid damage to the pumps by water hammer.

4.Unique design of type XS pumps working at high temperature using middle support to fasten the pump casing and using cooling seals oil lubrication bearing then pump suitable for working at 200℃ especially for suppling heated water to pipe net system.

5.Type XS pump casting parts can be vertically or horizontally mounted acoording to different working condition, with mechanical seals or packing seals.

6.Type XS pumps look beautiful with visible lines adopting industrially designing.

they can be widely used.

2.The pipelines arrangement of type XS pump looks simple and beautiful due to inlet and outlet at a same center line.

3.The same rotor of type XS pumps can be operated at reverse direction to avoid damage to the pumps by water hammer.

4.Unique design of type XS pumps working at high temperature using middle support to fasten the pump casing and using cooling seals oil lubrication bearing then pump suitable for working at 200℃ especially for suppling heated water to pipe net system.

5.Type XS pump casting parts can be vertically or horizontally mounted acoording to different working condition, with mechanical seals or packing seals.

6.Type XS pumps look beautiful with visible lines adopting industrially designing.

Cost Advantage:

1.The efficiency of XS pumps are 2%~3% higher than the same type pumps due to adopting advanced hydraulic model and thus minimum the operating costs.

2.The NPSH of type XS pumps are 1-3 meters lower than the same type split pumps due to using advanced hydraulic model and advanced manufacturing technique and thus minimize the foundation costs and extendling the using life.

3.Type XS pumps are suitable for any site working condition due to using SKF NSK bearing and other parts chosen by the customers and thus minimize the maintenance costs.

Maintaince Advantage:

1.It is very easy and simple to replace the mechanical seal due to usine container type machaniacl seal.

2.It is rapid easy to assembly and dismout the rotor parts due to using elastic ripess assembling.

3.It is unnecessary to make adjustment when assembling.

Technical Data

|

Flow rate

|

11600m3/h

|

|

Head

|

Up to 250m

|

|

Speed

|

970/1450/2900rpm

|

|

Temperature

|

Up to 105 ℃

|

|

Casing pressure

|

2.5Mpa

|

|

Shaft seal

|

Mechanical seal/Gland packing seal

|

|

Material

|

Cast iron/Ductile iron/Sus304/Sus316/Bronze

|

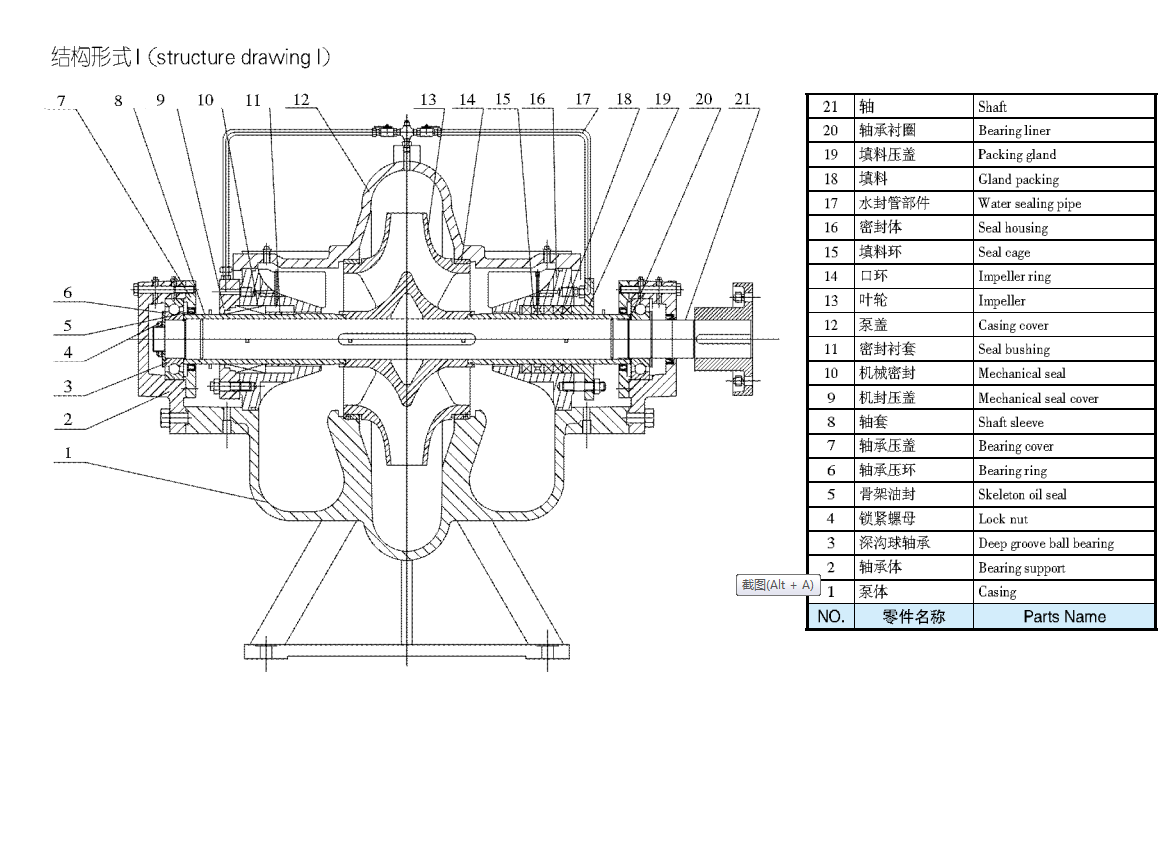

Structure Drawing

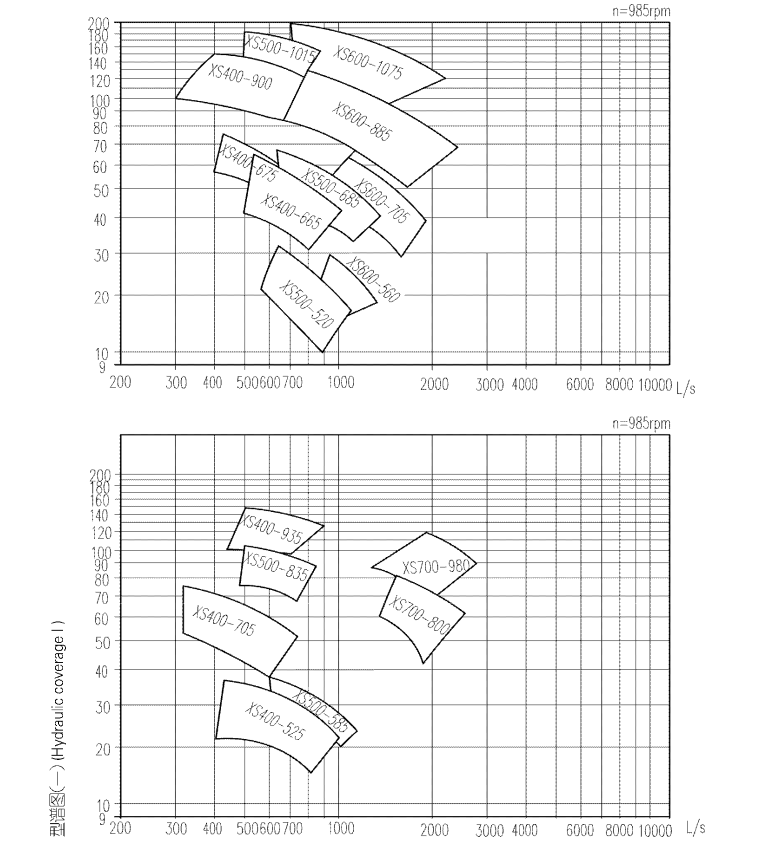

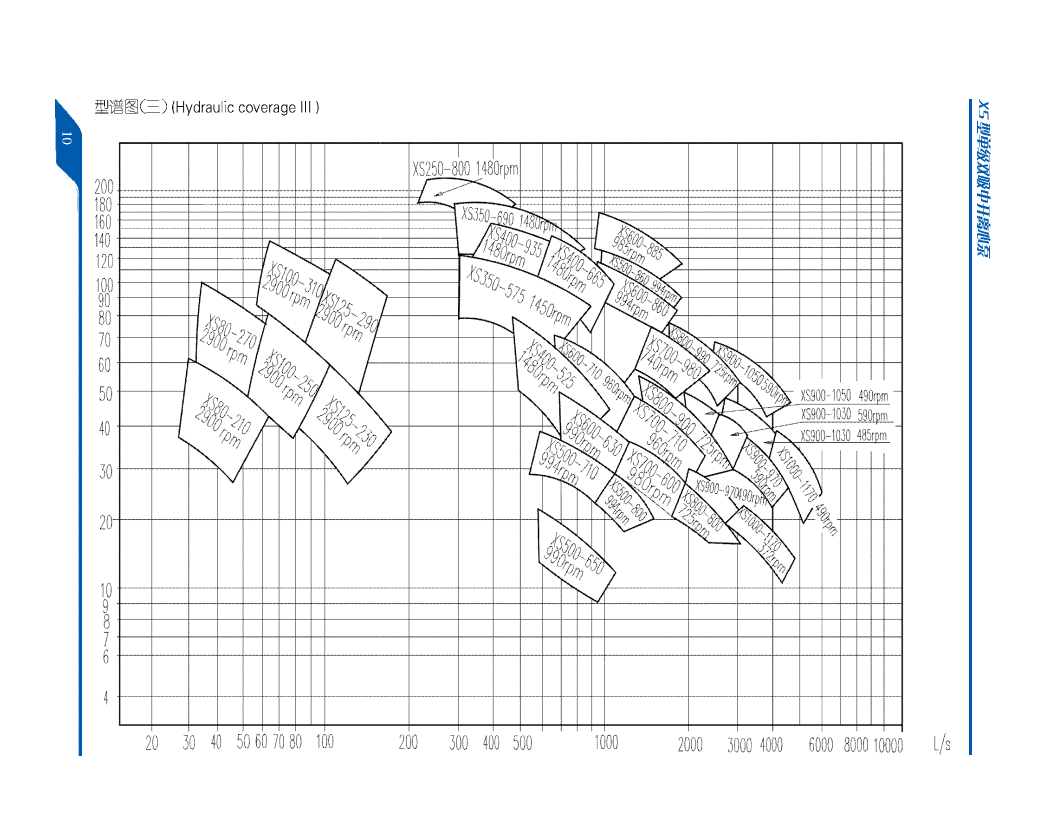

Spectrum

Details images

Customer onsite installation photos

Hot Searches