- Product Details

- {{item.text}}

Quick Details

-

Elongation (≥ %):

-

35

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

Chemical/Electronics, Industrial, Medical, Chemical

-

Grade:

-

Nickel, Monel/Inconel/Hastelloy/Nickel Alloy

-

Ni (Min):

-

58%

-

Model Number:

-

Inconel 718

-

Brand Name:

-

NXF

-

Product name:

-

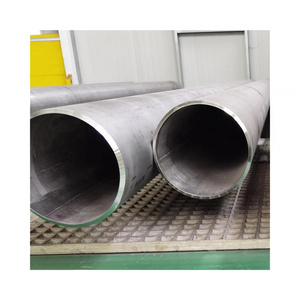

inconel alloy 718 Wire/ Strip/ Bar/ Pipe/ Sheet

-

Technique::

-

Forging & Cold Drawn

-

Temperature Range:

-

1260~1355℃

-

Material:

-

Inconel 718 600 625 725 X750

-

Tolerance:

-

±1%

-

Standard:

-

ASTM ASME SUS JIS DIN

-

Surface:

-

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D

Quick Details

-

Resistance (μΩ.m):

-

1.15

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

462

-

Elongation (≥ %):

-

35

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

Chemical/Electronics, Industrial, Medical, Chemical

-

Grade:

-

Nickel, Monel/Inconel/Hastelloy/Nickel Alloy

-

Ni (Min):

-

58%

-

Model Number:

-

Inconel 718

-

Brand Name:

-

NXF

-

Product name:

-

inconel alloy 718 Wire/ Strip/ Bar/ Pipe/ Sheet

-

Technique::

-

Forging & Cold Drawn

-

Temperature Range:

-

1260~1355℃

-

Material:

-

Inconel 718 600 625 725 X750

-

Tolerance:

-

±1%

-

Standard:

-

ASTM ASME SUS JIS DIN

-

Surface:

-

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D

Specification

|

item

|

value

|

|

Place of Origin

|

China

|

|

|

Jiangsu

|

|

Type

|

Nickel Plate

|

|

Application

|

Chemical/Electronics

|

|

Grade

|

hastelloy B/B-2/B3/C/C-276/C-22/C-4/X

|

|

Ni (Min)

|

55%

|

|

Resistance (μΩ.m)

|

1.25

|

|

Powder Or Not

|

Not Powder

|

|

Ultimate Strength (≥ MPa)

|

690

|

|

Elongation (≥ %)

|

40

|

|

Model Number

|

Hastelloy C-276

|

|

Brand Name

|

NXF

|

|

Product name

|

Hastelloy Alloy Wire/ Strip/ Bar/ Pipe/ Sheet

|

|

Technique:

|

Forging & Cold Drawn

|

|

Application

|

Chemical/Electronics

|

|

Temperature Range

|

1260~1355℃

|

|

Material

|

C-22/C-276/C-2000/C-4/B-2/B-3/G-30/G-35

|

|

Tolerance

|

±1%

|

|

Standard

|

ASTM ASME SUS JIS DIN

|

|

Surface Treatment

|

Polished

|

|

Specification

|

Wire: 0.01-10mm

Strip: 0.05*5.0-5.0*250mm Bar: φ4-50mm;Length 2000-5000mm Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm |

|

Product

Characteristics |

1.According to the preparation process can be divided into deformation superalloys,

casting superalloys and powder metallurgy superalloys. 2.According to the strengthening mode, there are solid solution strengthening type, precipitation strengthening type, oxide dispersion strengthening type and fiber strengthening type, etc.. |

|

Standard

|

GB,AISI,ASTM,DIN,EN,SUS,UNS etc

|

|

Inspection

|

ISO,SGS,BV and so on.

|

|

Application

|

High temperature components such as turbine blades, guide vanes, turbine disks,

high pressure compressor disks,machine manufacturing and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines |

|

Packaging

|

1. cases packed in wooden cases

2. paper packaging 3. plastic packing 4. foam packaging Packaging according to customer requirements or products |

|

Delivery

|

7-25days orAccording to the product

|

Product Description

Inconel 718

is an age-hardenable Alloy-chromium alloy that combines corrosion resistance with high strength and good fabricability. It has high creep-rupture strength at temperatures up to 700 OC. Its excellent relaxation resistance contributes to its application in springs.

Packing & Delivery

Packing:

Standard export seaworthy package . Water proof paper+Metal pallet+Angle bar protection+Steel belt or as required.

Delivery detail :According to the quantities and specifications of each order.Normal delivery time is from 7 to 15 days after receiving the deposit.

Delivery detail :According to the quantities and specifications of each order.Normal delivery time is from 7 to 15 days after receiving the deposit.

Hot Searches