- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3.2*0.9*1.3m

-

Weight:

-

5000 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380v/adjustable

-

Power:

-

70kw

-

Key Machines:

-

motor

-

Keywords:

-

macaroni production fusilli pasta production line

-

Water pump:

-

0.37kw

-

Heating:

-

18kw

-

Main material:

-

stainless steel

-

Raw material:

-

wheat flour

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Feature:

-

Low Energy High Speed

-

motor brand:

-

siemens

-

Function:

-

Multifunction

-

Application:

-

Application

Quick Details

-

Machinery Capacity:

-

100-150kg/h

-

Brand Name:

-

NEWEEK

-

Year:

-

2023

-

Dimension(L*W*H):

-

3.2*0.9*1.3m

-

Weight:

-

5000 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380v/adjustable

-

Power:

-

70kw

-

Key Machines:

-

motor

-

Keywords:

-

macaroni production fusilli pasta production line

-

Water pump:

-

0.37kw

-

Heating:

-

18kw

-

Main material:

-

stainless steel

-

Raw material:

-

wheat flour

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Feature:

-

Low Energy High Speed

-

motor brand:

-

siemens

-

Function:

-

Multifunction

-

Application:

-

Application

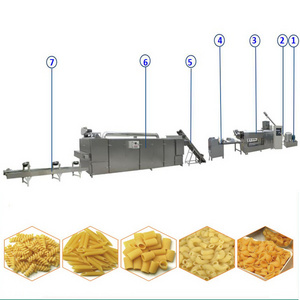

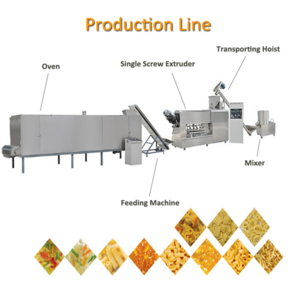

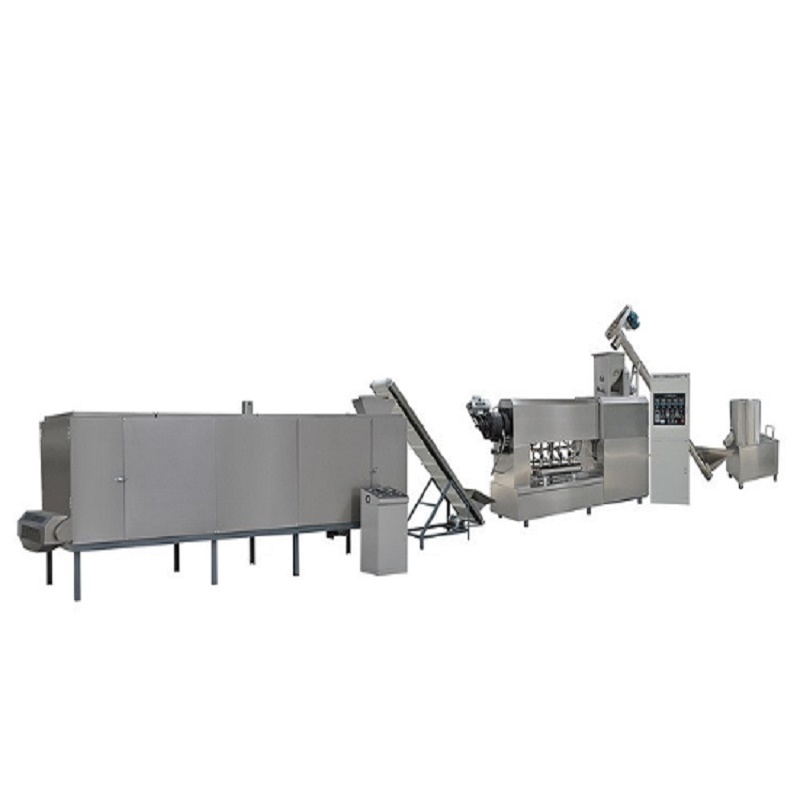

NEWEEK restaurant use tremella fusilli cookies biscuit maker macaroni production fusilli pasta production line

Product Description

1. The

fusilli pasta production line

mainly uses potato starch, corn starch and flour as raw materials to produce secondary puffed foods of various shapes and popular in the market by using a unique extrusion molding process. The production line has reasonable design, high degree of automation, precise extrusion parameter control, and the main machine is equipped with high and low pressure screws, which increases the use of raw materials, reduces costs and improves product quality.

2. The raw material is stirred with water and sent to the twin-screw main machine for extrusion forming. After being pulled by the tractor to the cutting and hanging rod machine, it is sent to the drying oven for drying. The dried material is cut and sorted by the cutting machine and sent to the packaging machine for packaging.

2. The raw material is stirred with water and sent to the twin-screw main machine for extrusion forming. After being pulled by the tractor to the cutting and hanging rod machine, it is sent to the drying oven for drying. The dried material is cut and sorted by the cutting machine and sent to the packaging machine for packaging.

Specification

|

Dimension(L*W*H)

|

3.2*0.9*1.3 m

|

|

Weight

|

5000KG

|

|

Voltage

|

380V/50HZ

|

|

Power

|

70 kw

|

|

Machinery Capacity

|

100-150 kg/h

|

|

Water pump

|

0.37kw

|

|

Heating

|

18kw

|

|

Production capacity

|

100-150 kg/h

|

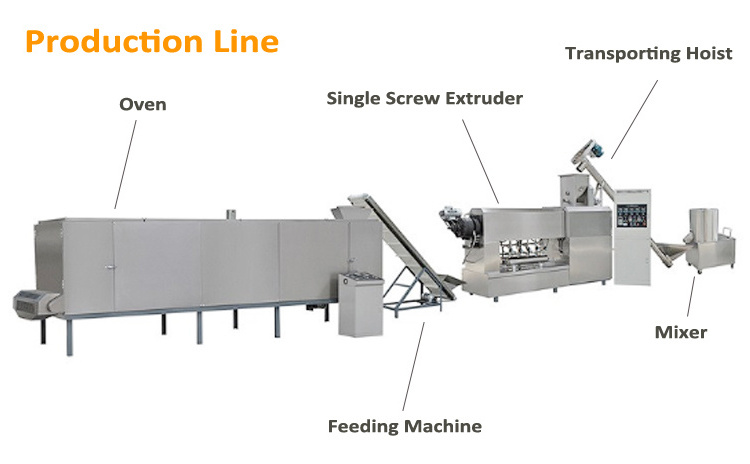

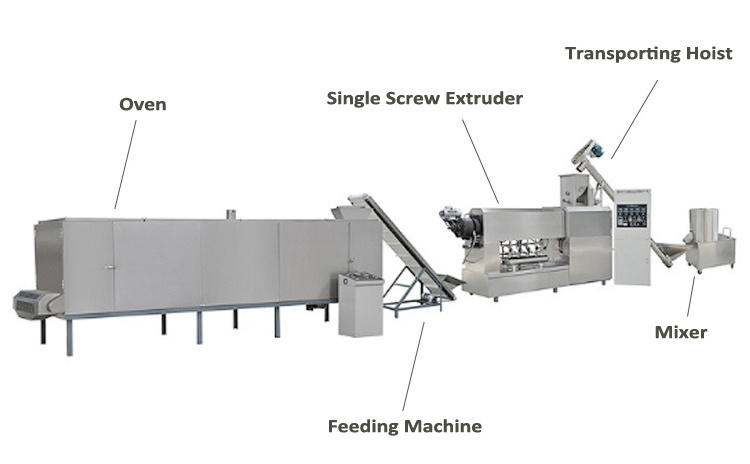

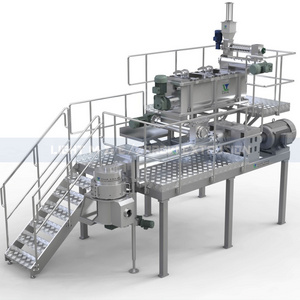

1.The

fusilli pasta production line

has a feeding system, an extrusion system, a rotary cutting system, a heating system, a transmission system, a cooling system and a control system.

2. Adopt advanced frequency conversion technology to make the equipment run more smoothly and save power;

3. The screw is treated by alloy steel nitriding, and the screw has a long service life;

Fourth, the process: raw material preparation → stirring → extrusion molding → conveying → drying → finished products →

(packaging)

4. Equipment configuration: mixing machine→feeding machine→extruder→transporting hoist→oven→packaging machine

2. Adopt advanced frequency conversion technology to make the equipment run more smoothly and save power;

3. The screw is treated by alloy steel nitriding, and the screw has a long service life;

Fourth, the process: raw material preparation → stirring → extrusion molding → conveying → drying → finished products →

(packaging)

4. Equipment configuration: mixing machine→feeding machine→extruder→transporting hoist→oven→packaging machine

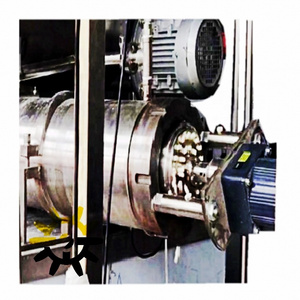

Details Images

Patent:Vacuum Pump.For the pasta ,the biggest problem is with bubbles and air inside.With the vacuum pump,which can extract air from feeding part,so there will be no any air and bubbles inside.

Function:

1.Specially decide single-screw system extreude and form the raw material into different sizes and shapes.

2.Controlling system,feeding system,extruding system,heating system, water cooling system, cutting

system,lubricating,system,vacuum technology,

Features:

1.Screw material is 38CrMoAl with nitriding treatment, the hardness is 60HRC.

2.Barrel material is alloy steel, hardness is 52HRC.

3.The gear box has forced lubrication system.

4.All the motor is controled by Inveter, which can save power and protect the extruder.

Function:

1.Specially decide single-screw system extreude and form the raw material into different sizes and shapes.

2.Controlling system,feeding system,extruding system,heating system, water cooling system, cutting

system,lubricating,system,vacuum technology,

Features:

1.Screw material is 38CrMoAl with nitriding treatment, the hardness is 60HRC.

2.Barrel material is alloy steel, hardness is 52HRC.

3.The gear box has forced lubrication system.

4.All the motor is controled by Inveter, which can save power and protect the extruder.

Packing & Delivery

Packing:

We usually pack the fusilli pasta production line in standard export wooden cases. We will wrap the entire machine with a plastic film to prevent the ravioli maker machine from scratching. Then fix the entire body with a wooden box to prevent the ravioli maker machine from being damaged due to transport bumps. If you have special request, please contact us in time.

Delivery:

For the samosa maker machine, we support TNT, DHL, FedEx, UPS. If you need, we also support delivery by ship. We can also deliver the fusilli pasta production line to your agent in China if you have.

We usually pack the fusilli pasta production line in standard export wooden cases. We will wrap the entire machine with a plastic film to prevent the ravioli maker machine from scratching. Then fix the entire body with a wooden box to prevent the ravioli maker machine from being damaged due to transport bumps. If you have special request, please contact us in time.

Delivery:

For the samosa maker machine, we support TNT, DHL, FedEx, UPS. If you need, we also support delivery by ship. We can also deliver the fusilli pasta production line to your agent in China if you have.

About us

Our company's products are reasonably designed, advanced in technology, well-made and stable in performance, and are well received by users. Since the establishment of the company, we have always demanded ourselves with a high starting point and high quality. Our products are made of high-quality raw materials, all designed and manufactured in accordance with international standards, reliable quality, sophisticated technology and perfect after-sales service. We rely on high-quality staff, coupled with

high-precision production equipment and strict testing methods, to produce high-quality products to give back to customers.

high-precision production equipment and strict testing methods, to produce high-quality products to give back to customers.

Certifications

As a company engaged in the food machinery industry for many years, we can guarantee the quality of

NEWEEK CE automatic electric industrial italian macaroni noodle extruder line machine

for make

macaroni noodle

, from material selection to processing, manufacturing, molding, and after repeated testing, we make products with strict and scientific attitude.

Our Services

1. We accept product customization. Regarding this

fusilli pasta production line

, if you have special requirements, any parts, we can customize according to your requirements. It is our constant pursuit to make the products that

customers are most suitable for.

2. We can guarantee the quality of the automatic gyoza machine, from material selection to processing, manufacturing, molding, and after repeated testing, we make products with strict and scientific attitude.

3. The warranty period for this automatic gyoza machine is 12 months. During the warranty period, machine parts other than wearing parts are damaged by non-human factors, we free of charge to provide new parts for replacement.

Thank you for your precious time! For more information about fusilli pasta production line , please feel free to contact me!

customers are most suitable for.

2. We can guarantee the quality of the automatic gyoza machine, from material selection to processing, manufacturing, molding, and after repeated testing, we make products with strict and scientific attitude.

3. The warranty period for this automatic gyoza machine is 12 months. During the warranty period, machine parts other than wearing parts are damaged by non-human factors, we free of charge to provide new parts for replacement.

Thank you for your precious time! For more information about fusilli pasta production line , please feel free to contact me!

Hot Searches