- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

None

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AONUO

-

Model Number:

-

LC-1128

-

Product Name:

-

Spray polyurea waterproofing Coatings anti corrosion polyurea

-

Solid content:

-

100%

-

Viscosity(25℃):

-

≤1000mPa.s

-

Part A Density(25℃):

-

A:1.080-1.160g/cm3

-

Part B Density(25℃):

-

B:1.030-1.100g/cm3

-

Theoretical Coating Amount(1mm):

-

1.05kg/m2

-

Volume Mixing Ratio:

-

A:B=1:1

-

Shelf Life:

-

1 year

-

Color:

-

Customized

-

Application:

-

Concrete

Quick Details

-

CAS No.:

-

None

-

Other Names:

-

Spray Polyurea Waterproofing Coating

-

MF:

-

None

-

EINECS No.:

-

None

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AONUO

-

Model Number:

-

LC-1128

-

Product Name:

-

Spray polyurea waterproofing Coatings anti corrosion polyurea

-

Solid content:

-

100%

-

Viscosity(25℃):

-

≤1000mPa.s

-

Part A Density(25℃):

-

A:1.080-1.160g/cm3

-

Part B Density(25℃):

-

B:1.030-1.100g/cm3

-

Theoretical Coating Amount(1mm):

-

1.05kg/m2

-

Volume Mixing Ratio:

-

A:B=1:1

-

Shelf Life:

-

1 year

-

Color:

-

Customized

-

Application:

-

Concrete

Protection Polyurea Material

The coating system consists of amine-terminated resin, arylamine chain extender and MDI prepolymer. The product is dual-component, self-cured and thick coating anti-corrosion material.

Recommended Applications

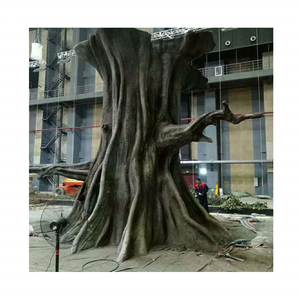

Applied to outer-wall waterproof protection of thermal insulation materials such as polyurethane foam, EPS foam, mineral cotton fiber and pearlite, and thermal insulation layer protection of light thermal insulation roof, large thermal insulation storage tanks and thermal insulation pipelines. It solves the problems that the outer protective iron skin of storage tanks used in coastal cities is easy to corrode and peel off in case of typhoon and the patch of the pipe system easily causes leakage.

Product Characteristics &Physical Properties

* Drying time is temperature, humidity, and film thickness dependent.

* Coating equipment status determines the property of coating.

* A test sample is cured in a thermostat of 65-70℃ for 24 hours.

Notes:

1.Polyurea product is intended for industrial use by properly trained professional applicators only.

2.Thoroughly mix container of B component with an air-driven power mixer for a minimum of 15 minutes prior to application.

3.Adding a nitrogen blanket is strongly recommended for use on the “A” component for storage after opening.

4.It is a100% solid production is strictly prohibit add any diluents.

5.The quality and fitness of the product is depending upon the proper mixture and application of the component by the applicator.

6.This specification is an accumulation of long term testing and experience. Published technical data and instructions are subject to change without notice.

7.For more information please contact us by email.

Packaging:

Part A: 220kilogram per drums.

Part B: 210 kilogram per drums. (Custom package available at additional charge)

One set:430 kilogram totally

Storage :

(1).The A component is affected by moisture and must be protected from moisture contamination. Containers are factory sealed with an inert gas to prevent contamination. Keep all containers tightly closed during storage. For further storage after opening, containers must be purged with nitrogen gas or dry air and tightly sealed to protect from moisture contamination.

(2).Store drums and pails in a cold, dry and ventilated location between 15 ℃ and 40 ℃.

(3).Twelve months in sealed unopened containers.

(4).Keep away from fire and heat source.

(5).Keep away from rain and sun.

Shipping:

10 days upon receipt of payment by shipment on Shanghai/ Qingdao Port.