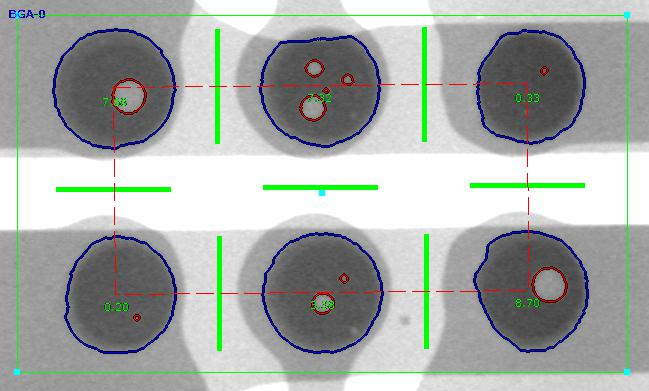

Enhanced BGA inspection function

NDX56 can quickly select and mark a single solder ball, or select the solder balls to be inspected by matrix box ; it can manually or automatically identify BGA solder balls and complete the inspection. Follow the system guidelines to easily complete the inspection process and ensure accurate and reliable inspection results.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

NEODEN

-

Model Number:

-

ND-56X

-

X ray tube Type:

-

Sealed Micro-Focus X-Ray Tube

-

Voltage Range:

-

40-90KV

-

Current Range:

-

10-200 μA

-

Max Output Power:

-

8 W

-

Micro Focus Spot Size:

-

15μm

-

Flat panel detector type:

-

TFT Industrial Dynamic FPD

-

Pixel Matrix:

-

768*768

-

Field of View:

-

65mm*65mm

-

Resolution:

-

5.8Lp/mm

-

A/D Conversion Bit:

-

16bits

Quick Details

-

Warranty:

-

1 Year

-

Power:

-

Electronic

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

NEODEN

-

Model Number:

-

ND-56X

-

X ray tube Type:

-

Sealed Micro-Focus X-Ray Tube

-

Voltage Range:

-

40-90KV

-

Current Range:

-

10-200 μA

-

Max Output Power:

-

8 W

-

Micro Focus Spot Size:

-

15μm

-

Flat panel detector type:

-

TFT Industrial Dynamic FPD

-

Pixel Matrix:

-

768*768

-

Field of View:

-

65mm*65mm

-

Resolution:

-

5.8Lp/mm

-

A/D Conversion Bit:

-

16bits

Product Description

ND-56X X ray inspection machine

ND56X is a small precise microfocus X-ray inspection equipment, suitable for R&D enterprise, laboratories, quality inspection rooms etc.

Spotlights

* Miniaturized equipment, easy to install and operate.

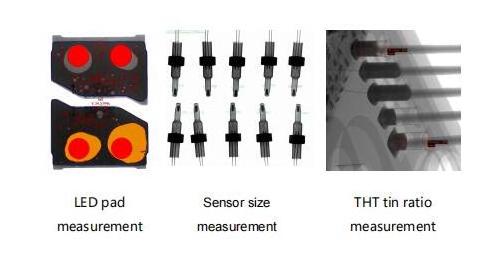

* Applicable to Chip, LED, BGA/CSR Wafer, SOP/QFN, SMT and PTU packaging, Sensors, Connectors, and Precision Castings inspection.

* High resolution design to get the best image in a very short time.

* Infrared automatic navigation and positioning function can select the shooting location quickly.

* CNC inspection mode which can quickly and automatically inspect multi-point array.

* Inclined multi-angle inspection makes it easier to inspect sample defects.

* Simple softwareoperation, low operating costs

* Applicable to Chip, LED, BGA/CSR Wafer, SOP/QFN, SMT and PTU packaging, Sensors, Connectors, and Precision Castings inspection.

* High resolution design to get the best image in a very short time.

* Infrared automatic navigation and positioning function can select the shooting location quickly.

* CNC inspection mode which can quickly and automatically inspect multi-point array.

* Inclined multi-angle inspection makes it easier to inspect sample defects.

* Simple softwareoperation, low operating costs

Specification

|

Model

|

ND56X

|

|

|

|

|

Type

|

Sealed Micro-Focus X-Ray Tube

|

|

|

|

Voltage Range

|

40-90KV

|

|

|

|

Current Range

|

10-200μA

|

|

|

|

Max Output Power

|

8W

|

|

|

|

Micro Focus Spot Size

|

15μm

|

|

|

|

Type

|

TFT Industrial Dynamic FPD

|

|

|

|

Pixel Matrix

|

768*768~1536*1536

|

|

|

|

Field of View

|

65*65~130*130mm

|

|

|

|

Resolution

|

5.8Lp/mm

|

|

|

|

Frme (1x1)

|

20~40 fps

|

|

|

|

A/D Conversion Bit

|

16

|

|

|

|

Dimensions

|

L850mm×W1000mm×H1700mm

|

|

|

|

Input Power

|

220V 10A/110V 15A 50-60HZ

|

|

|

|

Max Sample Size

|

280mm×320mm

|

|

|

|

Control System Industrial

|

PC WIN7/ WIN10 64bits

|

|

|

|

Net Weight

|

About 750KG

|

|

Features

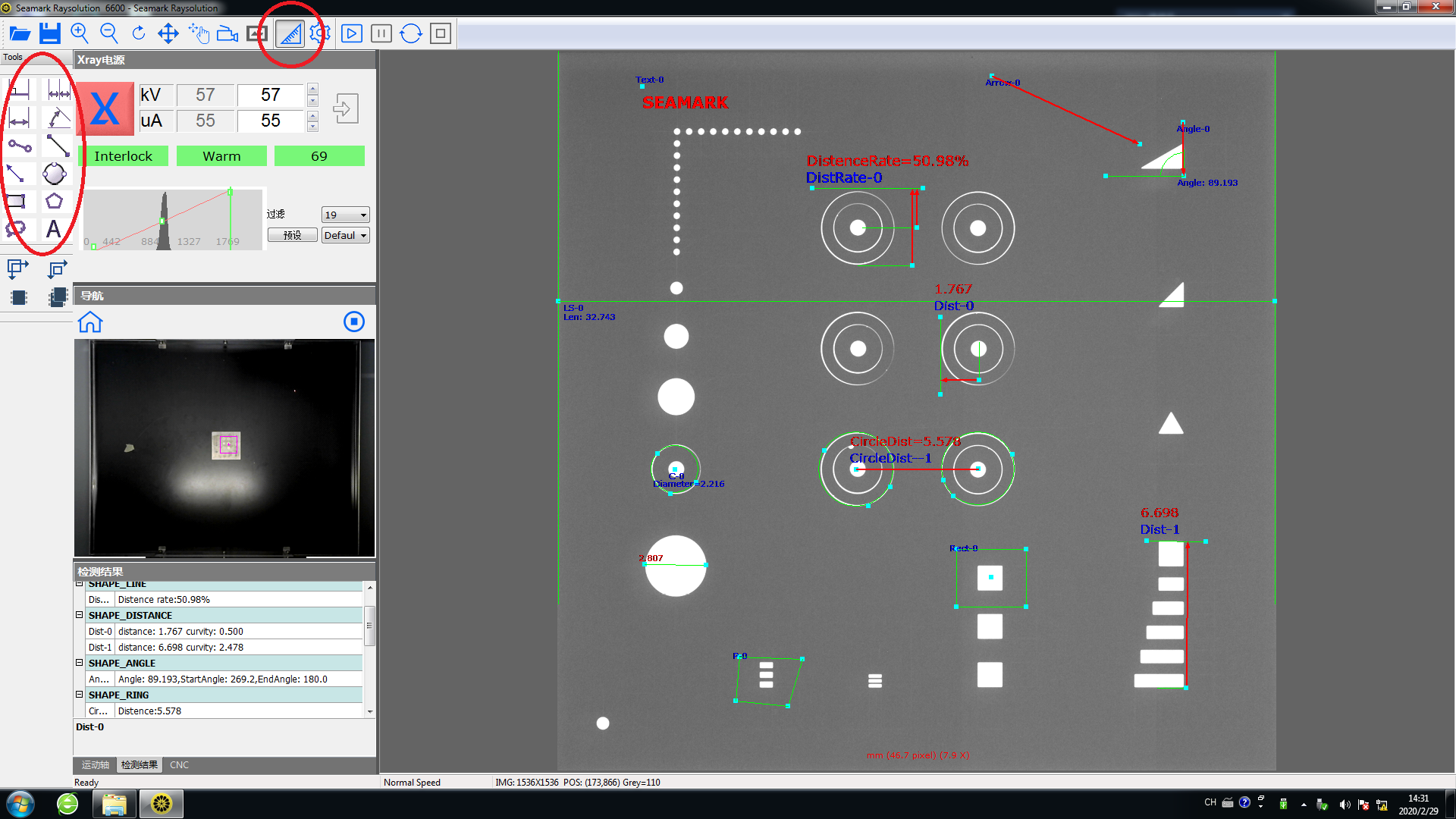

Measuring tools

Distance, distance ratio, lines distance, angle, arrow mark, circle radius, points distance, circle centers distance, circumference, hand-drawn polygon, hand-drawn freeform etc., can add text description.

Defect Inspection

Automatically detect defects

ND56X can automatically detect size, area, broken wire, bridging etc

Customizable image algorithm

Customerized software algorithms based on product features and request to achieve fully automatic defect inspection algorithms, including Y/N, crack, broken wire, offset, size, and quantity etc.

CNC automatic operation inspection

ND56X support CNC multi-point automatic inspection, based on product feature set multi-point coordinates for automatic inspection.

Automatic CNC operation detection

Automatically save images, generate reports, also support batch inspection.

Tilt / Rotate Function

Tilt angle inspection function

The ND56X loading platform support a tilt angle of ±30°. For cases where the photo taken on the front of a special device cannot identify the defect feature, the tilt function can be used to observe the device features at multiple angles, making it easier to analyze and identify the defect.

360°Rotating photo inspection function

Equipped with a rotating manipulator that can rotate 360 degrees to take images, no dead angle. defects.

SMT Line

Related Products

About Us

「

About NEODEN

」

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

With global presence in over 130 countries, the excellent performance, high accuracy and reliability of NeoDen PNP machines make them perfect for R&D, professional prototyping and small to medium batch production. We provide professional solution of one-stop SMT equipment.

In our global Ecosystem, we collaborate with our best partners to deliver a more closing sales service, high professional and efficient technical support.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist everywhere.

Payment & Shipping

FAQ

Q1: Do you provide software updates?

For customers who buy our machine, we can offer free upgraded software for you.

Q2: Does our machine need air supply?

We have vacuum pumps inside the machine, it does not need air supply.

Q3: This is the first time I use this kind of machine, is it easy to operate?

We have English user manual and guide video to teach you how to use the machine. If you still have question, pls contact us by email/skype/phone etc for online service.

Q4: How about the warranty?

We have 2 years warranty for NeoDen4, K1830, NeoDen9, In6, IN12 and 1 year for all other models with lifetime after-sale support.

Q5: How can I buy machine from you?

(1) Consult us on line or by e-mail;

(2) Negotiate and confirm the final price, shipping, payment method and other terms;

(3) Send you the proforma invoice and confirm your order;

(4) Make the payment according to the method put on proforma invoice;

(5) We prepare your order in terms of the proforma invoice after confirming your full payment . And 100% quality check before shipping;

(6) Send your order via express or by air or by sea.

For customers who buy our machine, we can offer free upgraded software for you.

Q2: Does our machine need air supply?

We have vacuum pumps inside the machine, it does not need air supply.

Q3: This is the first time I use this kind of machine, is it easy to operate?

We have English user manual and guide video to teach you how to use the machine. If you still have question, pls contact us by email/skype/phone etc for online service.

Q4: How about the warranty?

We have 2 years warranty for NeoDen4, K1830, NeoDen9, In6, IN12 and 1 year for all other models with lifetime after-sale support.

Q5: How can I buy machine from you?

(1) Consult us on line or by e-mail;

(2) Negotiate and confirm the final price, shipping, payment method and other terms;

(3) Send you the proforma invoice and confirm your order;

(4) Make the payment according to the method put on proforma invoice;

(5) We prepare your order in terms of the proforma invoice after confirming your full payment . And 100% quality check before shipping;

(6) Send your order via express or by air or by sea.

If you have any questions, welcome to

contact us

!

Hot Searches