- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Construction Cutting Picks Coal Mining Drill Machine part mining bit

-

Usage:

-

Mining / Quarrying / Tunneling

-

Item:

-

Drilling Equipment Bit Tricon Bit

-

keyword1:

-

cutting picks

-

Color:

-

Black or customized

-

Skirt:

-

Short skirt

-

Button Type:

-

Hemispherical/Parabolic/Ballistic / Conical

-

Advantage:

-

High Performance

-

Size:

-

U82,U84,U85,U92,U94,U95,S100,S120,S135,S150,S160,S170,U62,U47

-

MOQ:

-

10pcs

Quick Details

-

Weight (KG):

-

1

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

JinXin

-

Product name:

-

Construction Cutting Picks Coal Mining Drill Machine part mining bit

-

Usage:

-

Mining / Quarrying / Tunneling

-

Item:

-

Drilling Equipment Bit Tricon Bit

-

keyword1:

-

cutting picks

-

Color:

-

Black or customized

-

Skirt:

-

Short skirt

-

Button Type:

-

Hemispherical/Parabolic/Ballistic / Conical

-

Advantage:

-

High Performance

-

Size:

-

U82,U84,U85,U92,U94,U95,S100,S120,S135,S150,S160,S170,U62,U47

-

MOQ:

-

10pcs

Products Description

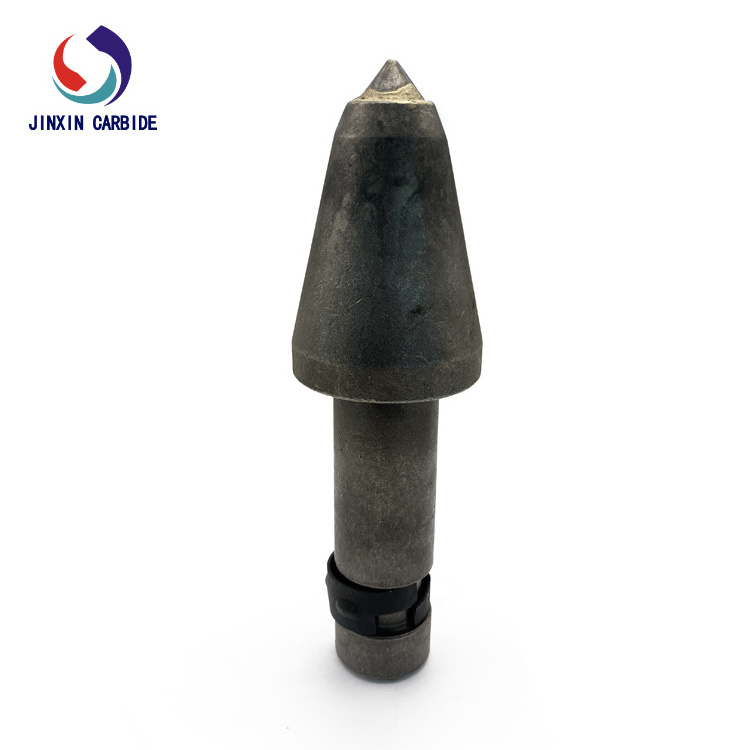

Carbide cutting teeth drill picks for hard rock

Advantages of tungsten carbide cutting picks:

1, Long service life.

2, High work efficiency.

3, Good efficiency: because of the change times greatly reduced, shorten the downtime of coal machine, reduce the cost of mining.

Advantages of tungsten carbide cutting picks:

1, Long service life.

2, High work efficiency.

3, Good efficiency: because of the change times greatly reduced, shorten the downtime of coal machine, reduce the cost of mining.

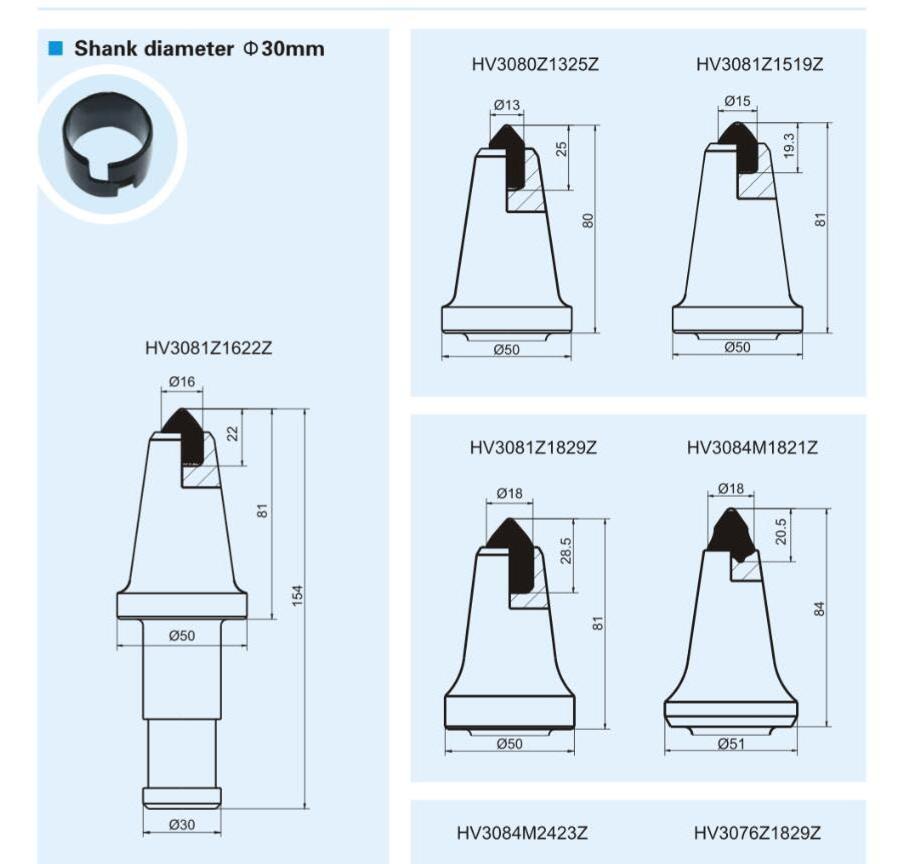

Parameter:

A: Cone hardness: HRC > 65

B: Pick rod hardness: HRC28°-32°

C: Surface hardness: HV > 2000 heat treatment process, up to 40-45 degrees

B: Pick rod hardness: HRC28°-32°

C: Surface hardness: HV > 2000 heat treatment process, up to 40-45 degrees

Application:

1.Apply to continuous miners, longwall shearers, roadheaders, and so on.

2.Through the wearing resistant test and the hardness test

3.With diversified designs can meet all cutting conditions.

4.With hard alloy inlaid have long life, low energy consumption and high efficiency.

5.Reducing downtime and costs.

6.It could be made according to Customers’specific demands.

1.Apply to continuous miners, longwall shearers, roadheaders, and so on.

2.Through the wearing resistant test and the hardness test

3.With diversified designs can meet all cutting conditions.

4.With hard alloy inlaid have long life, low energy consumption and high efficiency.

5.Reducing downtime and costs.

6.It could be made according to Customers’specific demands.

Product Paramenters

Details Images

Application Scenarios

Main Products

Hot Searches