Description:

Maydos JD2000 Epoxy Self-leveling Flooring System is two-component solvent-free epoxy paint. It has a nice appearance,

dust-resistant, corrosion-resistant and easy to clean. The flooring system has good bonding with

the solid base, good abrasion resistance and durability. Meanwhile, it has certain toughness, brittle-resistance and the load of a certain weight. The compressive strength and impact resistance ability is excellent.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

201-177-9

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Maydos

-

Model Number:

-

JD-2000

-

Drying time::

-

Touch dry: 2 hours Hard dry: 1 day

-

Compressive strength (Mpa)::

-

≥85

-

Impact resistance strength (Kg/cm)::

-

65

-

Flexural strength (Mpa)::

-

≥75

-

Adhesive force grade::

-

1

-

Hardness (Shore D)::

-

≥83

-

Abrasion resistance:

-

≤0.03

-

Rectangular Tear Strength (N/mm)::

-

≥50

-

Tensile Strength (Mpa)::

-

≥16

-

Resistance to 50% sulfuric acid:

-

no change

Quick Details

-

CAS No.:

-

79-10-7

-

Other Names:

-

Epoxy Floor Paint

-

MF:

-

Mixture

-

EINECS No.:

-

201-177-9

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Maydos

-

Model Number:

-

JD-2000

-

Drying time::

-

Touch dry: 2 hours Hard dry: 1 day

-

Compressive strength (Mpa)::

-

≥85

-

Impact resistance strength (Kg/cm)::

-

65

-

Flexural strength (Mpa)::

-

≥75

-

Adhesive force grade::

-

1

-

Hardness (Shore D)::

-

≥83

-

Abrasion resistance:

-

≤0.03

-

Rectangular Tear Strength (N/mm)::

-

≥50

-

Tensile Strength (Mpa)::

-

≥16

-

Resistance to 50% sulfuric acid:

-

no change

Products Description

Feature & Application

|

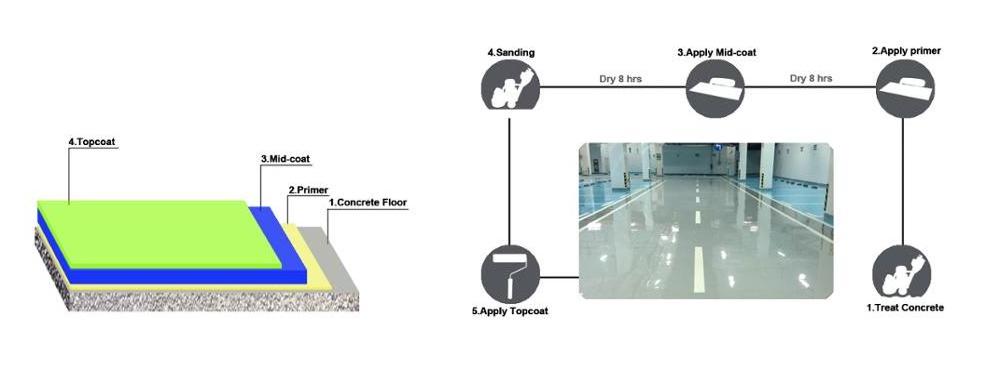

Surface preparation

|

Correct substrate preparation is critical for optimum performance. Surface should be sound, clean, dry and free from loose particles,oil,grease,and

other contaminants.

|

|

|

|

||||

|

Primer

|

Prepare a barrel, pour JD-D10A and JD-D10B in it based on 1:1. Stir the mixture well and then apply it with roller or trowel. The reference consumption is 0.15kg/m².The main purpose of this primer is to seal the substrate completely and avoid air-bubbles in the body coat. A second coat may be required depending on the oil absorption condition of substrate. The recoat time is about 8 hours.

|

|

|

|

||||

|

Inspection standard for the primer: even film with certain brightness.

|

|

|

|

|

||||

|

Undercoat

|

Mix WTP-MA and WTP-MB based on 5:1 first, then add quartz powder (1/2 of the mixture of A and B) into the mixture, stir it well and apply with trowel. The consumption quantity of A and B is 0.5kg /sqm. You can do it one coat at one time or two coats at two times. In the second case, the application interval is about 8 hours at 25 degrees. Sand the first layer, clean it and then apply the second layer. After the whole application, wait another 8 hours, grind it, clean the sanding dust and then continue the next procedure.

|

|

|

|

||||

|

Inspection standard for the undercoat: Non-sticky to hand, no softening, no nail print if you scratch the surface.

|

|

|

|

|

||||

|

Top coat

|

Mix JD-2000A and JD-2000 B based on 5:1 and then apply the mixture with spatula. The consumption quantity is 1.0kg/sqm.

|

|

|

|

||||

|

Maintenance

|

5-7 days. Don’t put the floor into use or wash it with water or other chemicals.

|

|

|

|

||||

Project case

Hot Searches