- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Vacorda

-

Model Number:

-

UHC

-

Material:

-

Stainless steel

-

Mode:

-

Float level sensor

-

Name:

-

Wireless Smart Level Gauge Magnetic Float Ball Type Liquid Level Gauge

-

Working temperature:

-

-40 ~80 celsius; ≤120celsius; ≤150 celsius

-

Meterial:

-

304,316L,1Cr18Ni9Ti,0Cr18Ni9,00Cr17Ni14Mo2,Titanium

-

Connection:

-

flange DN40~DN150 RF/PL

-

Measuring Range:

-

200-6000mm

-

Transmission distance:

-

more than 1000mm

-

Signal Output:

-

4-20mA

-

medium density:

-

≥0.5g/cm3

-

nominal pressure:

-

PN2.5-PN160

-

Keywords:

-

Fuel Level Sensor Float

Quick Details

-

Grade:

-

DIY, Industrial

-

Warranty:

-

1 Year

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

Vacorda

-

Model Number:

-

UHC

-

Material:

-

Stainless steel

-

Mode:

-

Float level sensor

-

Name:

-

Wireless Smart Level Gauge Magnetic Float Ball Type Liquid Level Gauge

-

Working temperature:

-

-40 ~80 celsius; ≤120celsius; ≤150 celsius

-

Meterial:

-

304,316L,1Cr18Ni9Ti,0Cr18Ni9,00Cr17Ni14Mo2,Titanium

-

Connection:

-

flange DN40~DN150 RF/PL

-

Measuring Range:

-

200-6000mm

-

Transmission distance:

-

more than 1000mm

-

Signal Output:

-

4-20mA

-

medium density:

-

≥0.5g/cm3

-

nominal pressure:

-

PN2.5-PN160

-

Keywords:

-

Fuel Level Sensor Float

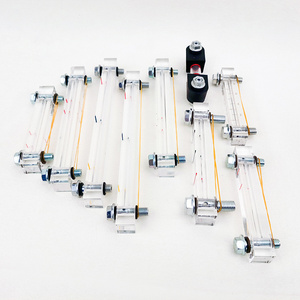

Submersible Wireless Smart Magnetic Float Ball Type Liquid Level Gauge Float Fuel Level Sensor

Magnetic floating fuel level sensor consists of reed, precise resistance and amplification transformation circuit and adopt imported advanced sensor componentsand signaltransmitters.When the magnetic lineof themagnetic float ball reaches a certainplace ofthe levelsensor, the reed closes, andthe floatball changeswith theheight of level interface.The amplification transformation circuit converts the change of the interface height into linear 4~20mADC signal to realize the measurementand transmissionof thelevel locationsignal.

Float Fuel Level Sensor Features

1. Simple structure, good stability and reliability.

2. Independent of medium’s physical and chemical states such as conductivity, dielectric constants, foam etc.

3. Appliable for all kinds of medium environment such as corrosive, toxic and explosive one.

4. Interface measurement or level measurement of 2 kinds of medium with different density.

5. Two-wire 4~20mADC signal output, 0.8’’ or 0.56” LED digital display.

6.Explosion-proof structure design for exploding environment

Float Fuel Level Sensor Parameters

| Measuring range | 200~6000mm(>6M customize) |

| Resolution factor | 10mm,5mm,20mm |

| singal output |

4~20mA(two-line) 2000/m(1/2",3/8") |

| Loading resistance | 500Ω |

| Transmitting | > 1000m |

| Working power supply | 16~30VDC |

| Density | ≥ 0.5g/cm 3 |

| Pressure | PN2.5~PN160(×0.1MPa)(Max pressure PN320) |

| Operating temperature | -40 ~ 80 °C, ≤ 120 °C, ≤ 150 °C |

| Float ball diameter | Φ30~Φ120 ( depending on pressure and density ) |

| Flange installation |

DN40~DN150/RF/PL(HG/T20592~2009)

customize

2'' thread(downward install) 1/2'' thread (upward install, resistance signaloutput) 3/8'' thread(upward install, resistance signal output) |

| Installation angle | ≤ ±25° |

| Electrical connection |

M20×1.5 female thread Three-lines screening cable |

| IP grade | IP65 |

| Explosion-proof grade | Exia II CT6Ga,EXd IICT6Gb |

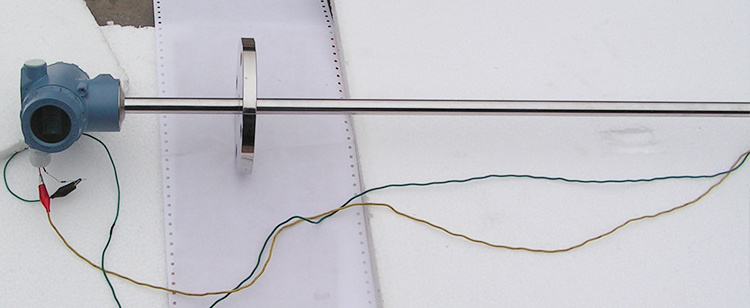

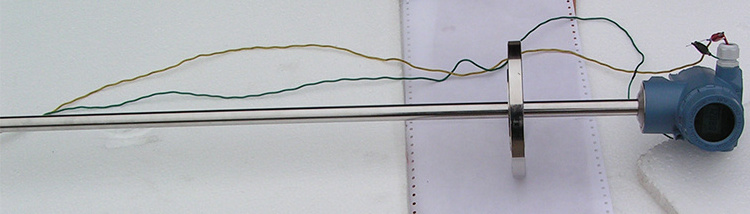

Product installation

Product Application

Sichuan VACORDA Instruments Manufacturing Co., Ltd.is a professional production-manufacturing enterprise specialized in designing, producing and marketing of instruments and apparatuses. Our company has been established for 23 years since 1997 to grow up to be a team of high-quality, united, hard-working and truth-seeking characters. Solid foundation has been established.

In 2017, we moved into our new factory whhich occupies the area about 20000 square meter, the workshop of 6900 square meter, R&D department of 1180 square meter , integrated office building of 1260 square meter, and we have established the high accuracy flow calibration lines.

Our company has got the ISO9001: 2000 international quality system certification in 2005, Import and export trading right in 2012, total 12 patents till 2016, the title of “national high-tech enterprise” and CE certificate for three categories product in 2014. Our company has owned trade marks as “vacorda”. At the same time, our company is preparing for more certificates for foreign market, such as IECEX, API, UL and so on, to lay a foundation for further international market.

Workshop and Skilled Workers

Certification and Equipment

Why Choose Us:

1.

23 years

of instrumentation equipment production experience

2. Product support

OEM / ODM

, export to more than

100

countries

3. The company area

20,000

square meters, and

150+

orders per month

4. Provide email, skype, whatsapp 24-hour one-on-one

technical support service

online

Q: The new magnetic flap liquid level gauge can't show liquid level?

A: 1.check whether there is block in by pass pipe 2.check the the density of medium 3.check whether the float ball is stucked by float ball.

Q: The longest length of magnetic flap liquide level gauge?

A: the length is customized,but in order to be convenient for transport,if the length is over 6m,we recommend

Q: If the float ball is installed at the wrong opposite direction,what's the influence?

A: reading level will be higher than true level,usually higher by length of floatball-70mm

Q: What's installation details of magnetic flap liquid level gauge ?

A: 1.before installation,check specification with label plate. 2.There shouldn't magnetic field within 400m

Q: There is problem in output signal 4--20mA?

A: 1.Check working power supply 2.check wiring 3,check load resistance 4.verify measuring range,zero point

Q: What's specification we need to know before purchasing magnetic flap liquid level gauge?

A: medium density,working temperature,working pressure,material,flange center to center distance,flange standard,whether need 4--20mA output signal;wether need level alarm