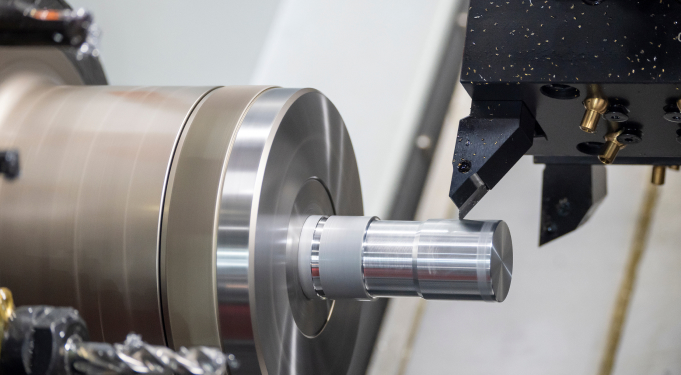

CNC turning is a CNC process where a cutting tool, a typically non-rotating component of the lathe or turning center, removes material from a rotating rigid material. This process produces different shapes and sizes depending on the turning operations

used.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

FUTE182401CY

-

Brand Name:

-

fute

-

Material:

-

Stainless steel, Copper, Aluminum, AL6061, Plastic

-

Surface Treatment:

-

Hot galvanized, Powder coating, Anodizing, Painting

-

Tolerance:

-

+/-0.02 - 01mm

-

Standard:

-

As drawing or sample

-

Extra services:

-

Automatic Lathe, Laser, Forging, Die casting

-

keywords:

-

CNC lathe turning part

-

CNC lathe turning:

-

CNC lathe turning part

-

Application:

-

Home appliance equipment,Automotive parts,Electrical equipment

-

Sample:

-

Available

-

QC System:

-

100% inspection before shipment

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

FUTE182401CY

-

Brand Name:

-

fute

-

Material:

-

Stainless steel, Copper, Aluminum, AL6061, Plastic

-

Surface Treatment:

-

Hot galvanized, Powder coating, Anodizing, Painting

-

Tolerance:

-

+/-0.02 - 01mm

-

Standard:

-

As drawing or sample

-

Extra services:

-

Automatic Lathe, Laser, Forging, Die casting

-

keywords:

-

CNC lathe turning part

-

CNC lathe turning:

-

CNC lathe turning part

-

Application:

-

Home appliance equipment,Automotive parts,Electrical equipment

-

Sample:

-

Available

-

QC System:

-

100% inspection before shipment

|

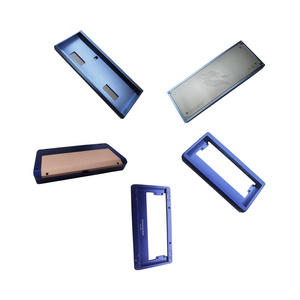

Custom CNC Machining Parts of Most Materials

|

|

|

|

|

||||

|

Quotation

|

According to your drawing(size, material, thickness, processing content, and required technology, etc)

|

|

|

|

||||

|

Tolerance丨Surface Roughness

|

+/-0.005 - 0.01mm 丨 Ra0.2 - Ra3.2(Custonize avaiable)

|

|

|

|

||||

|

Materials Avaiable

|

Aluminum, Copper, Stainless steel, Iron, PE, PVC, ABS, etc.

|

|

|

|

||||

|

Surface Treatment

|

Polishing, general/hard/color oxidation, surface chamfering, tempering, etc.

|

|

|

|

||||

|

Processing

|

CNC Turning, Milling, drilling, auto lathe, tapping, bushing, surface treatment, etc.

|

|

|

|

||||

|

Testing Equipment

|

CMM/Tool microscope/multi-joint arm/Automatic height gauge/Manual height gauge/Dial gauge/Roughness measurement

|

|

|

|

||||

|

Drawing Formats

|

PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF

|

|

|

|

||||

|

Our Advantages

|

1.) 24 hours online service & Quickly Quote/Delivery.

2.) 100% QC quality inspection before delivery, and can provide qualityinspection form. 3.) 20+ years of experience in the CNC machining area and have a senior design team to offer perfect modification suggestions. |

|

|

|

||||

Our service

CNC Turning

CNC Milling

It is a computer-controlled process involving using a cutting tool to remove part of a workpiece. The basic setup involves placing the workpiece on the machine’s table while the cutting tool/s attached to the spindle rotates and moves to shape the workpiece into a finished product.

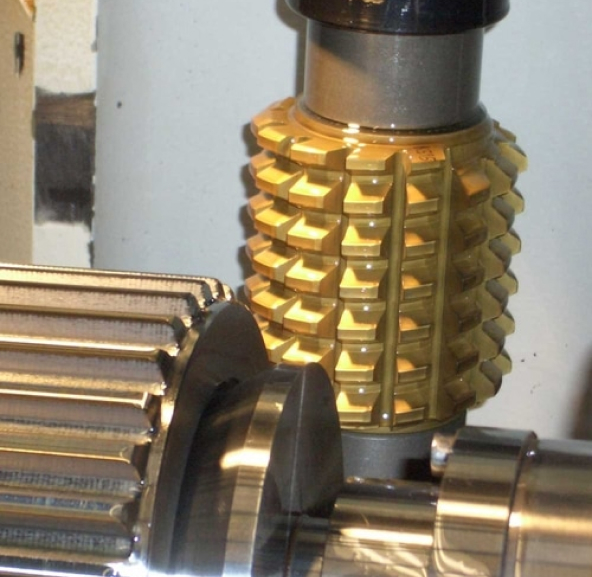

Gear hobbing

Hobbing is a machining process for cutting gear features on both metal and non-metal parts. The gear teeth (or splines) are progressively cut into a cylindrical piece of material by a series of cuts made by a cutting tool called a hob. Hobbing allows you to achieve various gear shapes and sizes such as spur gears, worm gears and bevel gears.

Production process

About our factory

Why choose us

1.Founded in 2002

2.

20+ Years

Experience

3.10,000 Square Meters workspace

4. Over 100 Employees

5.

300000 pcs Products Per Month

6. Certificates:

ISO9001

IATF16949

IS013485

Shenzhen Fute Hardware CO.,LTD was established in 2002.After years of development ,it has grown into a well-known supplier and professional company engaged in the research, development sales, service of plastic molds, injection molding, heat sink, and CNC processing. Fute has an excellent team focused on product development,custom manufacturing and has established a modern quality managementsystemin strict accordance with international standards. Our service hasbeen widely praised in the US and EU.

Testing Equipment

TQC

1.

Perfect orders 95.4% 100M+ Inspection points analyzed

2. The test accuracy can reach ±0.005mm.

3. Reduce the defective rate of delivered parts.

4.

lmported testing instruments

5. Can provide inspection reports and material

Product Introduction

Surface treatment

FAQ

Q1 : Do you customize products according to our design drawings ?

Q2 : Will my design drawings be safe when you get it ?

A2 : Yes, we will not publish your design to a third party unless your permission is obtained. We can sign NDA before you send the drawings.

Q3 : Does the company have the capacity for mass production?

A3 : The company has independent production and large-scale production conditions, one-stop service,70 CNC machine tools,40 injection molding machines, and has its own mold workshop.

Q4 : How to deal with surface treatment problems?

A4 : Sample color identification and dispensing ensure batch color consistency, strengthen manual inspection, avoid the defective products.

Q5 : How to avoid mass order quality problems?

A5 : Strengthen the prevention and inspection in advance of the process of production and processing, set important processes as the key point of quality control, follow up the inspection and defense throughout the process.

A1 : Yes, we are a professional metal manufacturing factory with experienced engineering team, which can make customized products according to customer drawings.

Q2 : Will my design drawings be safe when you get it ?

A2 : Yes, we will not publish your design to a third party unless your permission is obtained. We can sign NDA before you send the drawings.

Q3 : Does the company have the capacity for mass production?

A3 : The company has independent production and large-scale production conditions, one-stop service,70 CNC machine tools,40 injection molding machines, and has its own mold workshop.

Q4 : How to deal with surface treatment problems?

A4 : Sample color identification and dispensing ensure batch color consistency, strengthen manual inspection, avoid the defective products.

Q5 : How to avoid mass order quality problems?

A5 : Strengthen the prevention and inspection in advance of the process of production and processing, set important processes as the key point of quality control, follow up the inspection and defense throughout the process.

Hot Searches