- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2040*1500*1600mm

-

Power (kW):

-

6.5

-

Weight (KG):

-

700 kg

-

Panel Feed Speed(m/min):

-

12m/min

-

Power supply voltage:

-

380V/3P4H (3 live wires + 1 neutral wire)/50HZ

-

Air source pressure:

-

0.6-0.8Mpa

-

Hot melt adhesive type:

-

PUR/EVA

-

Glue pot temperature:

-

110C-210°C

-

Glue pot capacity:

-

2600ml

-

Gas storage capacity:

-

2L

-

Total power:

-

6.5KW

-

Edge banding strip width:

-

14-17mm

-

Edge banding strip thickness:

-

0.5-3mm (related to the edge banding strip material)

-

Plate thickness:

-

14-70mm (double-sided trimming) <14mm (single-sided trimming)

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KENAI

-

Voltage:

-

380v50HZ3P

-

Dimension(L*W*H):

-

2040*1500*1600mm

-

Power (kW):

-

6.5

-

Weight (KG):

-

700 kg

-

Panel Feed Speed(m/min):

-

12m/min

-

Power supply voltage:

-

380V/3P4H (3 live wires + 1 neutral wire)/50HZ

-

Air source pressure:

-

0.6-0.8Mpa

-

Hot melt adhesive type:

-

PUR/EVA

-

Glue pot temperature:

-

110C-210°C

-

Glue pot capacity:

-

2600ml

-

Gas storage capacity:

-

2L

-

Total power:

-

6.5KW

-

Edge banding strip width:

-

14-17mm

-

Edge banding strip thickness:

-

0.5-3mm (related to the edge banding strip material)

-

Plate thickness:

-

14-70mm (double-sided trimming) <14mm (single-sided trimming)

Product Paramenters

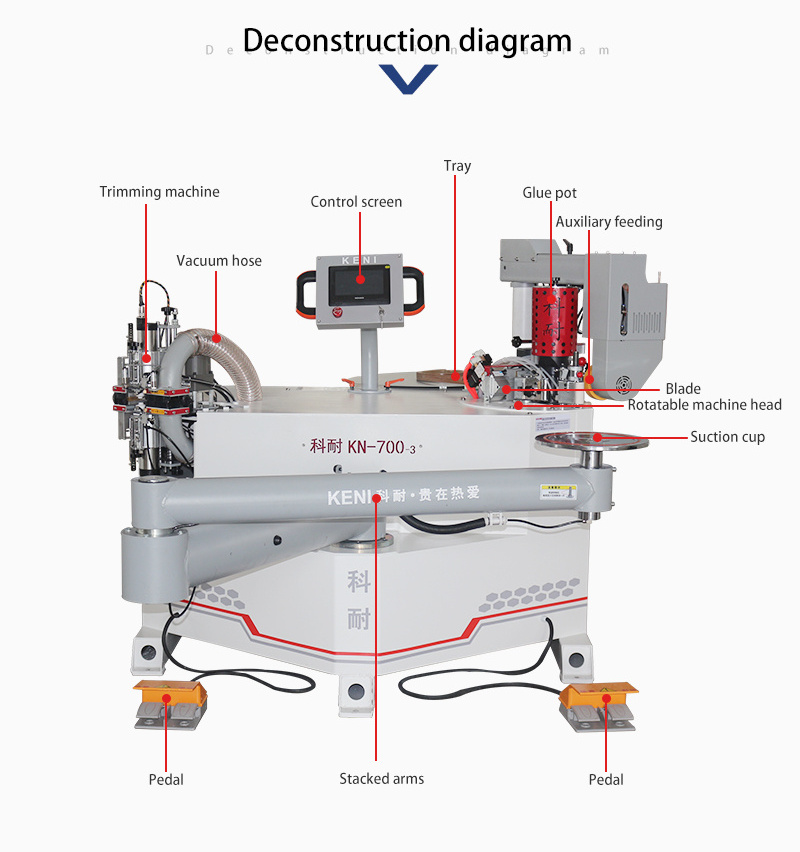

Automatic Curved Edge banding and Trimming Machine:

1.Curved board automatic feeding, suitable for round, oval, rounded rectangle shape.

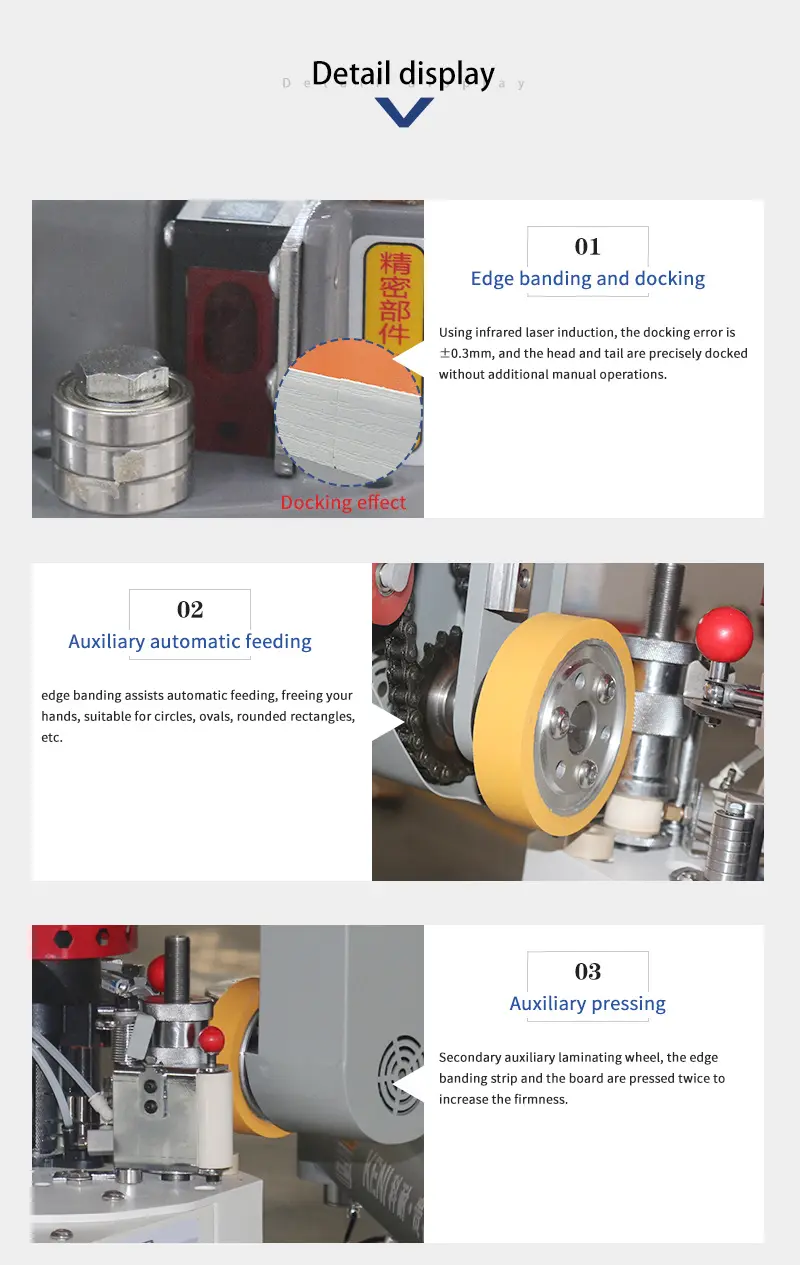

2.Infrared distance measurement, accurate docking (docking error ± 0.3mm), high precision, no need for manual operation to break

3.Upper glue pot design, PUR and EVA avaible , one key to discharge the glue, easy operate.

4.Servo motor, fast action response, low noise. The machine has good stability.

5.Feeding speed 0-30cm/s, high working efficiency.

6.The machine has 4 cleaning devices that automatically spray cleaning fluid. The spray time and interval time are adjustable.

1.Curved board automatic feeding, suitable for round, oval, rounded rectangle shape.

2.Infrared distance measurement, accurate docking (docking error ± 0.3mm), high precision, no need for manual operation to break

3.Upper glue pot design, PUR and EVA avaible , one key to discharge the glue, easy operate.

4.Servo motor, fast action response, low noise. The machine has good stability.

5.Feeding speed 0-30cm/s, high working efficiency.

6.The machine has 4 cleaning devices that automatically spray cleaning fluid. The spray time and interval time are adjustable.

7.The capacity of the glue pot has been increased to 2600ml and there is no need to add glue frequently. Rubber pot insulation function, one click to reduce heating waiting time.

8.Trimming unit, upper and lower trimming, high efficiency, flexible flat scraping device, easy to operate, no need for secondary processing.

9.Adopting a 2L pressure storage tank, it can ensure the normal operation of all pneumatic components of the entire machine when the external air pressure is unstable.

10.The touch screen can store 20 types of form data, making it easy to use and greatly improving work efficiency.

9.Adopting a 2L pressure storage tank, it can ensure the normal operation of all pneumatic components of the entire machine when the external air pressure is unstable.

10.The touch screen can store 20 types of form data, making it easy to use and greatly improving work efficiency.

|

Voltage

|

380V/50HZ/3phase

|

|

Total power

|

6.5KW

|

|

Edge banding speed

|

0-30cm/s

|

|

Air pressure

|

0.6-0.8Mpa

|

|

Vacuuming

|

φ150mm

|

|

Glue pot temperature

|

110℃-210℃

|

|

Tank capacity

|

2L

|

|

Glue material

|

PUR/EVA

|

|

Glue pot volume

|

2600ml

|

|

Strip thickness

|

0.5-3mm

|

|

Trimming

|

14-70mm both sides trimming, <14mm single trimming

|

|

Strip width

|

12-70mm

|

|

Size

|

1870*1400*1530mm

|

Details Images

Product Application

Hot Searches