- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

1 kN

-

Theoretical Shot Volume(cm³):

-

1 cm³

-

Injection Rate (g/s):

-

1 g/s

-

Injection Weight (g):

-

1 g

-

Screw Speed (rpm):

-

1 - 180

-

Screw diameter (mm):

-

1 mm

-

Screw L/D Ratio:

-

1

-

Distance between Tie Bars:

-

1

-

Weight (KG):

-

1

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

1 mm

-

Model Number:

-

TW-100V-G

-

Brand Name:

-

TaiWang

-

Power (kW):

-

5 kW

-

Clamping Force (kN):

-

85 kN

-

Certification:

-

CE

-

Injection Rate:

-

78 103cc/s

-

Opening Stroke:

-

40 46mm

-

Injection Weight:

-

192 254 gr

-

Color:

-

Green

-

Screw Diameter:

-

40mm - 52mm

-

Injection pressure:

-

2104 cm2 - 1304cm2

Quick Details

-

Plasticizing Capacity(g/s):

-

1

-

Mold Height(mm):

-

1 - 500 mm

-

Ejector Stroke(mm):

-

1 mm

-

Ejector Force(kN):

-

1 kN

-

Theoretical Shot Volume(cm³):

-

1 cm³

-

Injection Rate (g/s):

-

1 g/s

-

Injection Weight (g):

-

1 g

-

Screw Speed (rpm):

-

1 - 180

-

Screw diameter (mm):

-

1 mm

-

Screw L/D Ratio:

-

1

-

Distance between Tie Bars:

-

1

-

Weight (KG):

-

1

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

1 mm

-

Model Number:

-

TW-100V-G

-

Brand Name:

-

TaiWang

-

Power (kW):

-

5 kW

-

Clamping Force (kN):

-

85 kN

-

Certification:

-

CE

-

Injection Rate:

-

78 103cc/s

-

Opening Stroke:

-

40 46mm

-

Injection Weight:

-

192 254 gr

-

Color:

-

Green

-

Screw Diameter:

-

40mm - 52mm

-

Injection pressure:

-

2104 cm2 - 1304cm2

| TW-100V-G | ||||

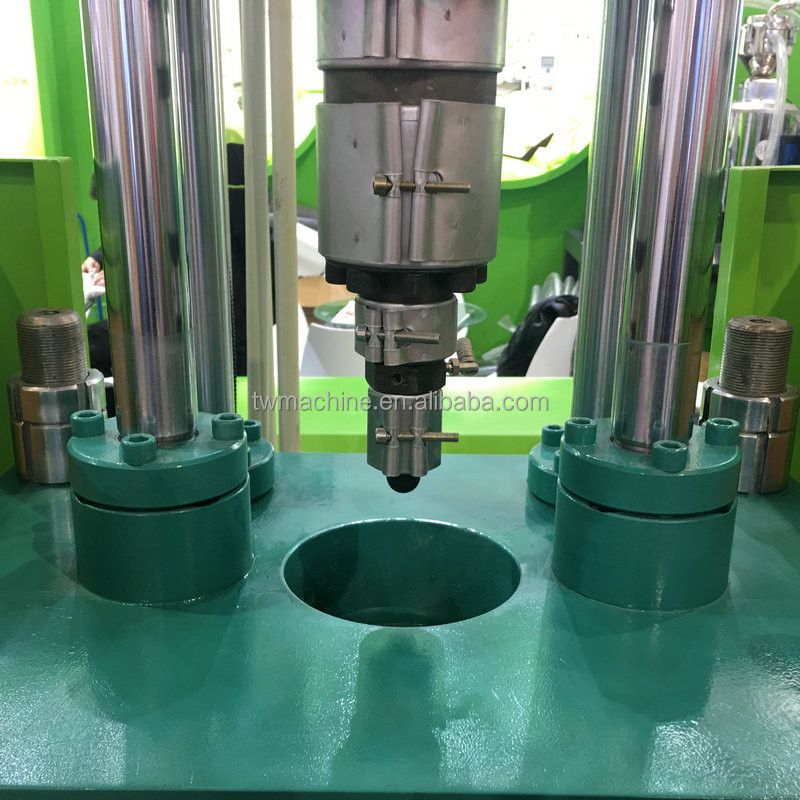

| INJECTION UNIT | Item | Unit | TW-100V-G | |

| Screw Diameter | mm | 40 46 | ||

| Injection Pressure | kgf/cm2 | 2104 1591 | ||

| Injection Capacity | cm3 | 214 282 | ||

| Injection Weight(P.S) | gr | 192 254 | ||

| oz | 7 9 | |||

| Injection Rate | cc/s | 78 103 | ||

| Screw Speed | r.p.m | 0~180 | ||

| Screw Stroke | mm | 170 | ||

| Nozzle Stroke | mm | 200 | ||

| Nozzle Contact Force | tf | 3.5 | ||

| CLAMPING UNIT | Clamping System | …… | Hydraulic | |

| Clamping Force | tf | 100 | ||

| Clamping Stroke | mm | 250 | ||

| Max.Mould Space | mm | 500 | ||

| Min.Mould Height | mm | 250 | ||

| Overall Size Of Platens(H×V) | mm | 800*600 | ||

| Space Between Columns(H×V) | mm | 560*360 | ||

| Hydraulic Ejector Force (H×V) | tf | 2.7 | ||

| Ejector Stroke | mm | 50 | ||

| OTHERS | Drive Motor | kw | 14.9(20HP) | |

| Heater | kw | 8.5 | ||

| Dimension of Machine(L×W×H) | m | 2.3*1.6*4.2 | ||

| Weight Of Machine | t | 5 | ||

| Shipping Size(L×W×H) | m | 2.5*1.8*3.7 | ||

| Shipping Weight | t | 5.8 | ||

| Oil Tank Capacity | L | 340 | ||

| Cooling Water | l/hr | 1000~1200 | ||

1.Vetical injection and vertical clamping design

2.Space-saving compact design,more convenient to take product out.

3.Adopts the international brand component for keeping machine running stable, reliable and accurately.

4.Multistage precision molding heaters .

5.Glass fiber board insulating.

6.Sliding table and rotary table as option, specially suitable for the insert molding production.

7.Special feeding design, precise metering.

8.Optional vacuum evacuation meaning.

1.Machine is surrounded by wrapping paper.

2.Split the machine into two primary parts which decide to dimension of machine in the fixable wooden box.

3.Grease the parts with antirust oil in order to avoid corrosion during transit.

4.Fasten wooden box by nail and stick cautions.

5.Ship package to designated Port by crane.

7.The professional supervises till package reach port smoothly.