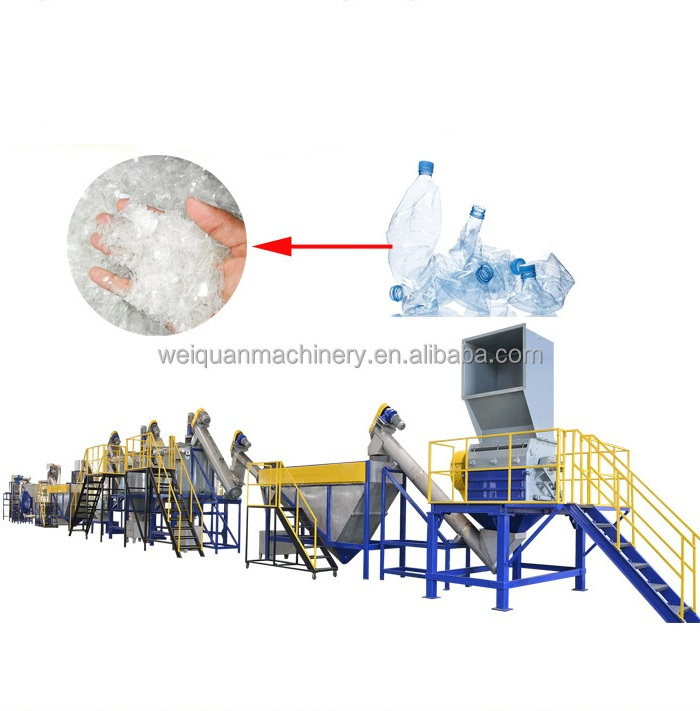

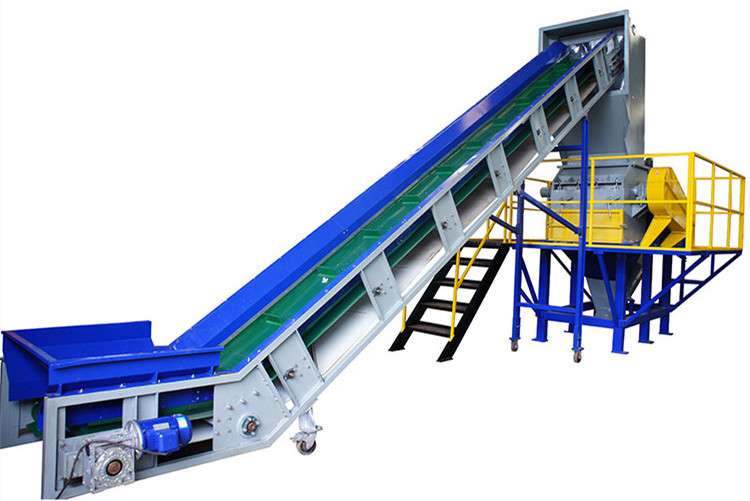

>>PET Plastic Bottle Washing Line

is one of the main recycling series of our company. This system has smart modular design aiming at blow molding packaging bottle/box/cup/barrel/bucket and injection waste recycling.

>>Including sorting, size reduction, metal removing, cold and hot washing, high efficiency friction washing and drying modular. Which can remove ferrous and nonferrous metals, sand, oil, glue, paper and many other different contaminants efficiency.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

weiquan

-

Application:

-

plastic recycling

-

Production Capacity (kg/h):

-

300 - 2000

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

50*5*6m

-

Power (kW):

-

100

-

Weight (T):

-

20

-

Water supply:

-

2-3 CBM Per Hour

-

Man power:

-

2-4 person

-

Machine color:

-

Customized

-

Steam use:

-

Optional

-

Final flake size:

-

50-80mm

-

Production Capacity:

-

300-2000kg/h

-

Crusher mesh screen diameter:

-

80mm

-

Speed Control:

-

Inverter control

-

Washing method:

-

Friction Washer

-

Machine Material:

-

Stainless Steel

Quick Details

-

Machine Type:

-

PP PE Bottle Washing Line

-

Max.Production Capacity (kg/h):

-

2000

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

weiquan

-

Application:

-

plastic recycling

-

Production Capacity (kg/h):

-

300 - 2000

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

50*5*6m

-

Power (kW):

-

100

-

Weight (T):

-

20

-

Water supply:

-

2-3 CBM Per Hour

-

Man power:

-

2-4 person

-

Machine color:

-

Customized

-

Steam use:

-

Optional

-

Final flake size:

-

50-80mm

-

Production Capacity:

-

300-2000kg/h

-

Crusher mesh screen diameter:

-

80mm

-

Speed Control:

-

Inverter control

-

Washing method:

-

Friction Washer

-

Machine Material:

-

Stainless Steel

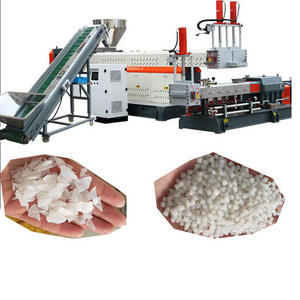

Product Overview

Made In China Plastic Bottles Recycle Polyester Staple Fiber Making Price Plastic Pet Bottle Recycling Machine

Application

Product Paramenters

|

Model

|

Capacity

|

Installed Power

|

Steam Use

|

Water Supply

|

Manpower

|

Area Required

|

|

MT-500

|

500 kg/hr

|

190 KW

|

Optional

|

4-5 m3/hr

|

4-6 Person

|

60*5*5 m

|

|

MT-1000

|

1000 kg/hr

|

260 KW

|

Optional

|

6-8 m3/hr

|

8-10 Person

|

80*8*5 m

|

|

MT-2000

|

2000 kg/hr

|

400 KW

|

Suggest Use

|

10-15 m3/hr

|

10-12 Person

|

80*8*5 m

|

|

MT-3000

|

3000 kg/hr

|

600 KW

|

80,000 Kcal

|

20-30 m3/hr

|

12-16 Person

|

100*8*10 m

|

|

MT-4000

|

4000 kg/hr

|

800 KW

|

100,000 Kcal

|

30-40 m3/hr

|

15-20 Person

|

135*10*10 m

|

|

MT-5000

|

5000 kg/hr

|

1000 KW

|

120,000 Kcal

|

40-50 m3/hr

|

15-20 Person

|

135*10*10 m

|

1)The capacity of the whole line is between 150kg/h and 4000kg/h

2) Contact material parts are SUS304, thickness more than 3mm, long service life.

3)The production line uses the world famous brand components -- SKF bearing, Siemens contactor, Japan

4RKC temperature, ABB inverter, Siemens PLC control.

4)The whole production line through CE certification, ISO9001 certification.

Process flow

De-baling(bale opener)------Trommel----- Label Scrapping(label remover) ------ Manual Sorting and Metal Detecting-----Wet Grinding(crusher)-------Screw conveyor------Gravity Separation(floating washer)-------Screw conveyor------Chemical Washing for PET Flakes(Hot washer)-------Screw conveyor------High speed friction washer ------- Screw conveyor------Floating washing tank ------- Dewatering machine--------Drying pipe system--------Label separator(Zigzag air label separator type)------Packing/storage hopper

Hot Searches