- Product Details

- {{item.text}}

Quick Details

-

Top Diameter:

-

Customized

-

Bottom Diameter:

-

Customized

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DSN

-

Model Number:

-

Graphite mold DSN1000

-

Product name:

-

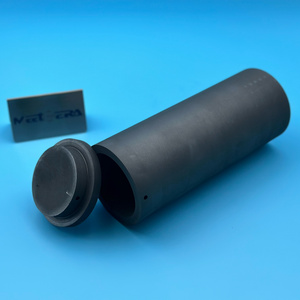

Graphite Crucible

-

Materials:

-

High Pure Graphite Materials

-

Size and Shape:

-

Custom Maching

-

Key words:

-

Isostatic Graphite Mould

-

Ash Content:

-

0.2%-0.3%

-

Grain Size:

-

0.02mm-4mm

-

Bending Strength:

-

15 - 40MPa

-

Advantage:

-

Lubrication

-

Color:

-

Black

-

Usage:

-

Welding processment

Quick Details

-

Type:

-

Isostatic

-

Application:

-

Metallurgy Industry

-

Height:

-

Customized

-

Top Diameter:

-

Customized

-

Bottom Diameter:

-

Customized

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DSN

-

Model Number:

-

Graphite mold DSN1000

-

Product name:

-

Graphite Crucible

-

Materials:

-

High Pure Graphite Materials

-

Size and Shape:

-

Custom Maching

-

Key words:

-

Isostatic Graphite Mould

-

Ash Content:

-

0.2%-0.3%

-

Grain Size:

-

0.02mm-4mm

-

Bending Strength:

-

15 - 40MPa

-

Advantage:

-

Lubrication

-

Color:

-

Black

-

Usage:

-

Welding processment

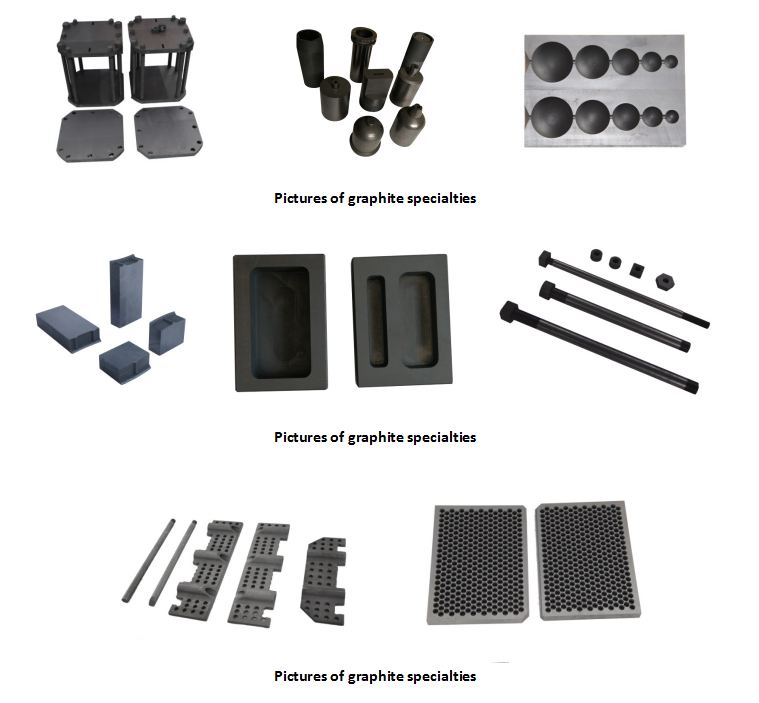

P

rofessional solution provider including pyrolytic graphite, vapor chamber, silicone pad, die-cutting, specialties graphite, ceramic filtration membrane.

Services in telecommunications, industrial consumer electronics and medical, new energy vehicles, machinery, environmental engineering.

Used in soft circuit board, backlight module, touch panel, mechanical hardware, finished product assembly and environmental protection engineering industry.

Four factories: Jiangsu, Jiangxi, Anhui and Shandong.

Certificates: ISO9001,IATF16949,ISO14001,UL...

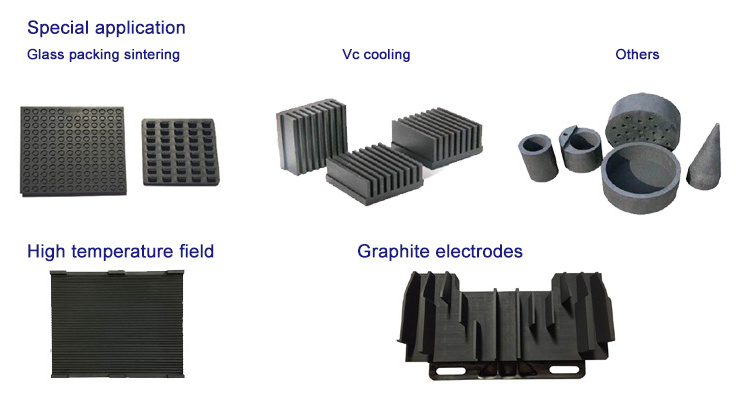

Specialty carbon graphite materials include medium grain graphite, fine grain graphite, and ultra-fine grain graphite.

Specialty carbon products (Carbon specialties) will realize the carbon's extensive potential. They are high-performance products that underline the development of key industries such as electronics, machinery, and metallurgy. They are also used in cutting-edge fields of science such as semiconductors aviation and the aerospace industry.

Features of specialties graphite:

* High temperature resistance, and the melting point is 3850±50°C, the boiling point is 4250.

* Low ash content, high purity, avoiding pollution to your products.

* Graphite material is easily to machine into any shapes you like.

* High mechanical strength

* Good sliding properties

* High thermal conductivity

* High thermal shock and chemical resistance

* Food safety

* Low wettability

* High corrosion resistance and oxidation resistance

* Good electrical conductivity

* High density and high mechanical strength

* Proper electrical conductivity

Main properties of graphite specialties

|

Model

|

Density

|

Compression Strength

|

Flexural Strength

|

Resistance

|

Ash

|

Grain Size

|

|

|

g/cm3

|

Mpa

|

Mpa

|

μΩm

|

%

|

|

|

|

>=

|

>=

|

>=

|

<=

|

<=

|

|

|

SG72

|

1.62

|

28

|

14

|

8

|

0.3

|

1,2,4mm

|

|

SG72

|

1.72

|

36

|

18

|

7.5

|

0.3

|

2,0.8mm

|

|

SG75

|

1.75

|

48

|

24

|

7.5

|

0.3

|

325mesh

|

|

SG80

|

1.80

|

52

|

28

|

7.5

|

0.2

|

325mesh

|

|

SG85

|

1.85

|

62

|

36

|

7

|

0.2

|

325mesh

|

Notes of operating graphite crucibles:

1.

The crucible should be stocked in the dry situation

2.

Carry the crucible lightly

3.

Warm the crucible in the drying machine or near the

furnace. The warming temperature should be up to 500℃.

4.

The crucible should be put under the furnace month flat.

5.

When put the metal into the crucible, you should take the crucible capacity as your reference. If the crucible is too full, it will be damaged by expansion.

6.

The clamps shape need as that of crucible. Avoid the

concentrate stressed destroy of the crucible.

7.

Clean the crucible regularly and lightly.

8.

The crucible should be put in the center of the furnace and leave some distance between the crucible and furnace.

9.

Turn the crucible once in one week and this will help lengthen the service life.

10.

The flame should not touch the crucible directly.

11.

24 hours constant use will make crucibles have longer service life.

The smelt soup in the crucible should be cleared out when the furnace stop working, in order to avoid molten soup

solidificating and will be expanded when fire to reheat, and affect the service life of crucible or even burst.

12.

We suggest that about 2 months for crucible melting aluminum alloy (every week for melting copper alloy), hanging out to check whether there is something wrong in the surface, and clean furnace hearth as well as turn the crucible, this operation ishelpful to prolong the service life of crucible.

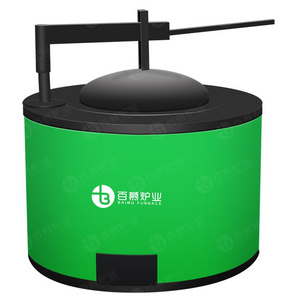

|

Product Name

|

Industry

|

Application

|

|

Crucible, Boat, Dish, etc.

|

|

Melting, refining and analysis

|

|

Dish, Molds, Ingot Chassis, etc.

|

Metallurgy

|

EDM graphite electrodes, semiconductor manufacturing, iron, steel and nonferrous metal making, continuous casting, metallurgy pressing machine

|

|

Graphite Roller, etc.

|

|

Heat treatment of steel plate in furnace

|

|

Conduit, Skateboard, etc.

|

|

Aluminum molding

|

|

Graphite Pipe

|

|

Masonry furnace and other heat resistance material

|

|

Graphite Block

|

|

Masonry furnace and other heat resistance material

|

|

Chemical Equipment

|

|

Heat exchanger, reaction tower, distillation columns, absorption equipment, centrifugal pumps, etc.

|

|

Electrolytic Plate

|

|

Salt solution and baking molten salt electrolyte

|

|

Electrolytic Mercury

|

|

NaCI electrolyte

|

|

Grounded Anode

|

|

Electrical anticorrosion

|

|

Motor Brush

|

Electricity

|

Commutator, slipping ring

|

|

Current Collector

|

|

Skate, slide, trolley

|

|

Current Collector

|

|

Switches, relays

|

|

Mercury Ferry And Electronic Pipe

|

Electronics

|

Anode, grid pole, repelled pole, ignition pole of the Mercury rectifier and anode, grid electrode

|

|

Graphite Bearing

|

Machinery

|

High temperature resistance sliding bearing

|

|

Sealing Element

|

|

Sealing ring, stuffing box seal, packing seal

|

|

Product Element

|

|

Braking in plane and vehicle

|

|

Nuclear Graphite

|

Nuclear Power

|

Deceleration materials, reflective materials, shielding materials, nuclear fuel, support devices, etc.

|

Quality policy

The policy aims at satisfying our customer by way of initializing an updated quality management and sticking to the top requirement of "quality first" in an attempt to achieve an elite project finally.

Quality objective

Provide our customer with products in full line with relevant contract and standard by way of strictly conforming to quality control procedure and intensifying avoiding common quality faults to be sure of an effective operation of the quality assurance and quality control system, achieve a zero quality accident rate and realize good project construction quality.

Quality Assurance System and Function

Establish quality assurance and effective quality control system before construction in order to ensure the realization of construction quality objective.

Work - Post Responsibility

Responsibility of Project Manager

Dasen has a research and development team with 2 ph. D. leading more than 20 high-end R & D technicians. Dasen also owns a sound management process and advanced development tools.

ISO9001-2015, ISO14001-2015, IATF16949-2016, UL

We obtained more than 30 invention patents and utility model patent and gained the honor: "scientific and technological innovation enterprises", "Jiangxi Province special new enterprises", "national high-tech enterprises".

DSN

adheres to

Taiji

culture

of respecting social and loving people, fulfilling social responsibility, publicizing the environment and development, and realizing the common growth of society, enterprises and employees.

As Heaven's movement is ever vigorous, so must a gentleman ceaselessly strive along. DSN will work hard to press ahead and create new splendor.

FAQ

Q1. Can you introduce your main products?

Sure. We mainly produce thermal conductive graphite sheet, thermal silicone pad and structure ceramic. For the graphite specialties, we can offer customized shape according to customer's specific demand. Materials include the extrude/molded/isostatic graphite of all grades.

Q2.What is your MOQ?

1 piece (graphite block/boat/plate/rod/round).

Q3. Can you offer free samples?

Yes, usually we can offer small products sample F.O.C., but do not pay the courier fee.

However, if the sample is expensive, like large size, Dasen has to charge basic cost of the sample.

Q4. Do you accept OEM or ODM orders?

Yes, we do.

Q5. How about your delivery time?

Usually 15 to 30 days after payment, 7-10 days if we have raw materials in stock.

Q6. Do you test your goods before delivery?

Yes, we do test before delivery.

Q7. How do you keep long-term business relationship?

1. Good quality and competitive price to ensure mutual benefit;

2. Quick reply and sincere service.