- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Xinnuo

-

Voltage:

-

380v/50Hz/3Phases

-

Dimension(L*W*H):

-

7.0*1.5*1.55m

-

Weight:

-

About 4.0T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Product name:

-

glazed metal tile panel ibr roll former forming machine for ppgi roof

-

Decoiler:

-

Manual one, can load 5 tons raw material

-

Roller Station:

-

11 rows

-

Roller Diameters:

-

72mm

-

Roller Material:

-

Carbon 45# steel

-

Raw material width:

-

As users needs

-

Blade Material:

-

Cr-12, quenched, Cr-plating size 0.05mm

-

Backboard Thickness:

-

14mm

-

Cutting Method:

-

Hydraulic mould cutting

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE, ISO, TUV

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

12-18m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Xinnuo

-

Voltage:

-

380v/50Hz/3Phases

-

Dimension(L*W*H):

-

7.0*1.5*1.55m

-

Weight:

-

About 4.0T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Product name:

-

glazed metal tile panel ibr roll former forming machine for ppgi roof

-

Decoiler:

-

Manual one, can load 5 tons raw material

-

Roller Station:

-

11 rows

-

Roller Diameters:

-

72mm

-

Roller Material:

-

Carbon 45# steel

-

Raw material width:

-

As users needs

-

Blade Material:

-

Cr-12, quenched, Cr-plating size 0.05mm

-

Backboard Thickness:

-

14mm

-

Cutting Method:

-

Hydraulic mould cutting

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE, ISO, TUV

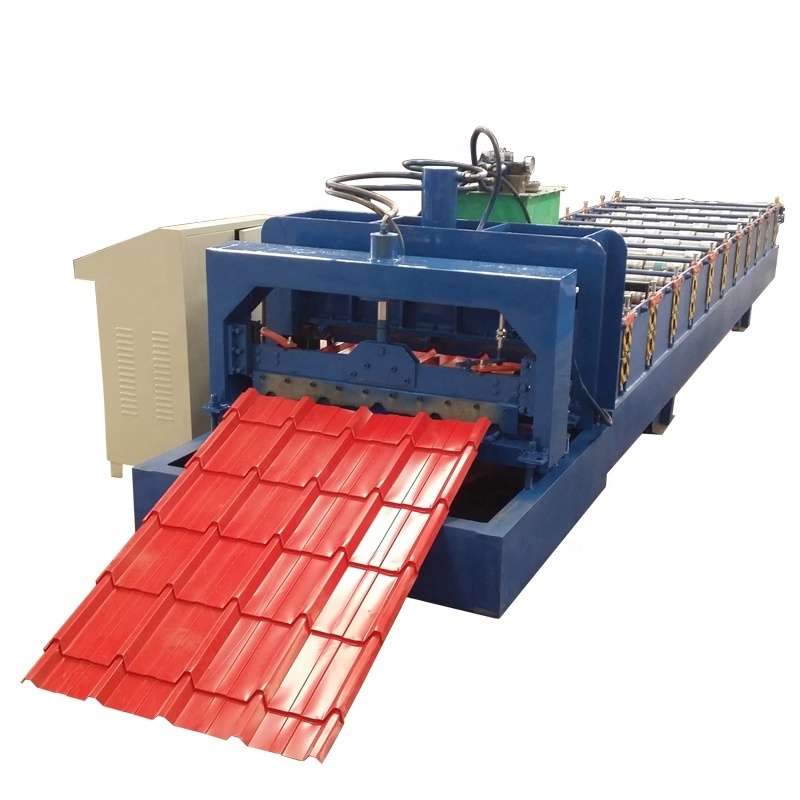

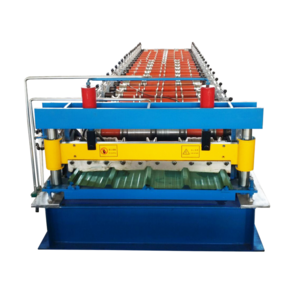

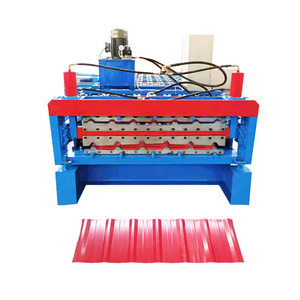

840 automatic pro rib glazed metal tile making pressing panel ibr roll former forming machine for ppgi roof

Main parameters:

| NO. | Main parameter of 840 glazed tile machine | |

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | 1000mm |

| 3 | Thickness of the plate | 0.3-0.8mm |

| 4 | De-coiler | Manual one, can load 5 tons raw material |

| 5 | Rollers for forming | 11 rows |

| 6 | Diameter of the roller | 72mm |

| 7 | Rolling material | Carbon Steel 45# |

| 8 | Main motor power | 4kw |

| 9 | Productivity | 0-3m/min |

| 10 | Cutting method | Hydraulic mould cutting |

| 11 | Material of the cutting blade | Cr12 |

| 12 | Hydraulic cutting power | 3kw |

| 13 | Processing precision | Within 1.00mm |

| 14 | Control system | Delta PLC control |

| 15 | Side panel of machine | 14mm |

| 16 | Main structure of the machine | 300 H steel |

| 17 | Weight | About 4.0T |

| 18 | Dimensions | 7.0*1.5*1.55m |

| 19 | Voltage | 380V 50Hz 3phases(changeable as needs) |

| 20 | Certificate | CE/ISO |

| 21 |

Configurations |

Manual Uncoiler ,Guiding Platform ,Coil Strip Leveler ,Main Machine Of Roll Forming ,Electro-Motor, Glazed Tile Pressing Device ,Cutting Device ,Hydraulic Station ,PLC Control, Supporter Table. |

| 22 | Custom | According to customer's requirements |

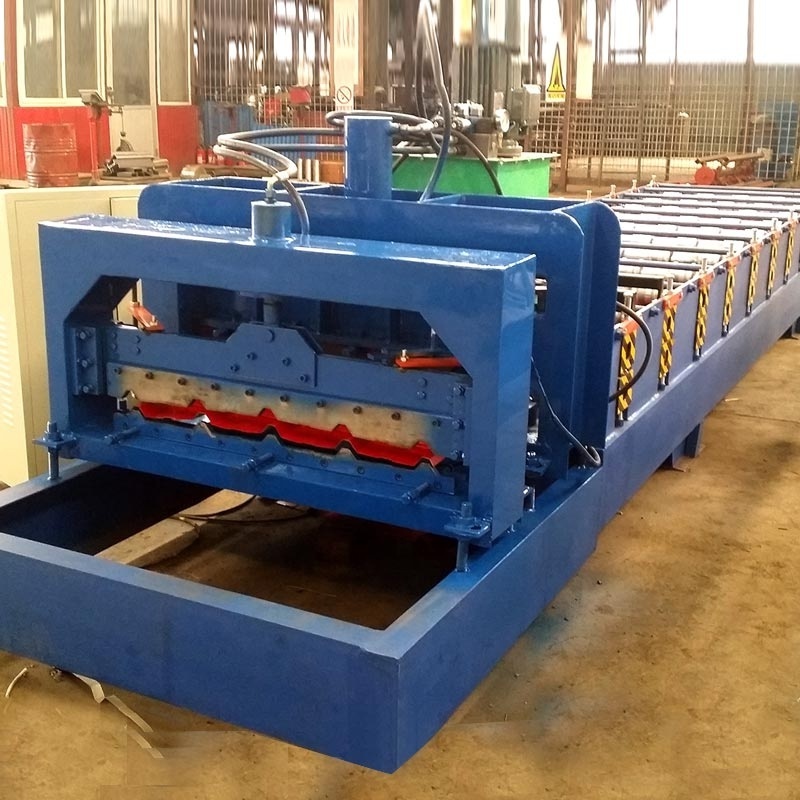

Equipment components:

Man-made uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting.

Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building manufacturing, and have features such as nice appearance and durable.

|

|

Our machine |

Influence of the machine |

|

Main forming machine body |

High strength H300 steel. machine through milling machine after welding

|

Sturdy and durable, ensure the plate standard |

|

Material of the roller |

High grade No.45 forged steel

|

Ensure the forming effect of the panel and the use age will be longer,the surface of the panel |

|

Material of the cutting |

GCr12 steel with quenched treatment |

Cutting is out of shape not easily and use age will be longer,the panel size precision |

|

Material of the active shaft |

High grade solid No.45 carbon steel,Shaft diameter is 72mm. |

Improve the integrated mechanic feature of the shaft and keep product standard |

|

Control system |

PLC control system,some elements are imported from Japan and Germany |

Machine become more accurate and more stable |

Terms of Payment: 30% of the total contract value paid by T/T as down payment, the rest 70% of the total contract value to be paid by T/T after inspection by buyer in seller's factory while before delivery.

Delivery: 30 days after receipt of advance payment

Service: we send technician to your country to fix the machine.The buyer should bear all the cost including: visa, Round trip tickets and suitable accommodation, also buyer should pay salary 80USD/day.

Warranty: 12 months limited warranty

During warranty: parts are free but buyer pay for the shipping fee.