- Product Details

- {{item.text}}

Quick Details

-

Shape:

-

semi-transparent

-

Material:

-

PFA

-

Chemical name:

-

PFA Perfluoroalkoxy

-

Appearance:

-

Semi-transparent particles or white powder

-

Certificate:

-

ISO9001

-

Characteristic:

-

Non-Stick Superior Dielectric Superior creep resistance

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Engineering plastics

-

color:

-

white

-

Shape:

-

semi-transparent

-

Material:

-

PFA

-

Chemical name:

-

PFA Perfluoroalkoxy

-

Appearance:

-

Semi-transparent particles or white powder

-

Certificate:

-

ISO9001

-

Characteristic:

-

Non-Stick Superior Dielectric Superior creep resistance

PFA products Parts Customized high quality PFA plastic injection molding Oem Parts Cnc Machining pfa products

PFA(Per Fluor Alkoxy)

has a wide range of operating temperatures, maintaining stable physical properties from -200°C to 260°C and performing well even under extreme conditions. It has stable chemical properties, high resistance to chemicals such as acids, alkalis, and organic solvents, and is not susceptible to corrosion and erosion.

Product Display

Properties of PFA Plastic

1.Chemically inert to most industrial chemicals & solvents.

2.Good creep resistance at upper service temperature.

3.High melt strength, stability at high processing temperatures.

4.Excellent crack and stress resistance.

5.Low coefficient of friction and higher flex life.

6.Exceptionally low dielectric constant & dissipation factor.

7.Resists ignition and does not promote flame spread.

8.Wide range of temperatures: from -200℃ (-392℉) to 260℃ (500℉)

9.In comparison to other fluoropolymers, it demonstrates greater mechanical strength, stiffness and wear resistance.

3.High melt strength, stability at high processing temperatures.

4.Excellent crack and stress resistance.

5.Low coefficient of friction and higher flex life.

6.Exceptionally low dielectric constant & dissipation factor.

7.Resists ignition and does not promote flame spread.

8.Wide range of temperatures: from -200℃ (-392℉) to 260℃ (500℉)

9.In comparison to other fluoropolymers, it demonstrates greater mechanical strength, stiffness and wear resistance.

PFA Products

PFA has all the features as FEP and also has the following improvements: resistant to a constant temperature of 250 ° C and more than 100 times the bend / flex life compared FEP.

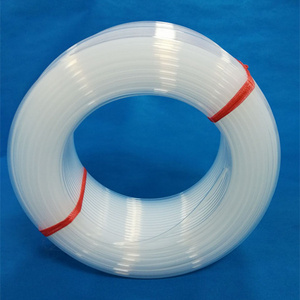

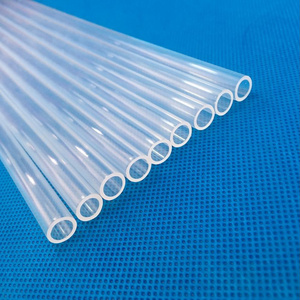

PFA extruded tubes and hose

Excellent for higher temperatures and again large stocks held. Custom extrusions are possible.

PFA heat shrinkable sleeves

Excellent for higher temperatures up to 260 °C and better flex life. The ultimate non-stick surface.

PFA film

A large stock of PFA film in many thicknesses and widths. For extra demanding applications.

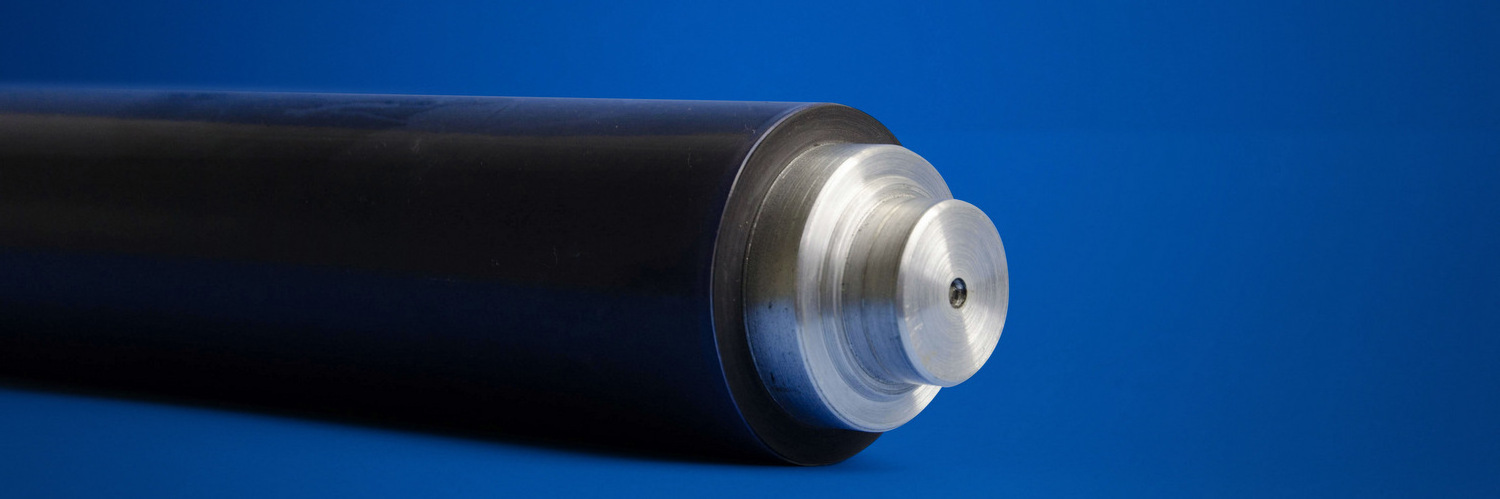

PFA parts

Precision machined PFA semi-finished parts, from single pieces to very large series.

Our Advantages

01.Quality Assurance

We work with the best raw material suppliers:DUPONT、DAIKIN、SOLVAY.

02.Design and Development

With 26+ years' experience in fluoropolymer manufacturing, we deliver precise and innovative fluoroplastic solutions for your technical applications.

03.Processing Capacity

We have the high quality CNC and EDMmachines from HAAS,MOKRON,OKUMA,AGIE,MAKINO,such as: 4-axis and 5-axis

CNC machines,can offer ostable and accurate processing ability.

04.Quality Control

All products are strictly implemented in accordance with IS09001 quality management system standards, and strictly undergo two-dimensional and three-dimensional testing.

05.

Worry-free After-sales

All products will be tested in small batches first to make sure there are no problems before mass production starts.

Need a luoropolymer Solution?

Discuss your requirements with an expert today.

Customized Service

Comprehensive Improvement of Services

to Solve Your Problems

1. Product Design and Development.

2. Customized Processing According to Drawings and Samples.

3. Solve Your Problems with High Quality and High Level.

4. Customized Injection Mold Parts and CNC Processing.

5. Provide One-Stop Services for Your Project.

CNC Machining

By using CNC milling & turning, we can make a wide range of prototypes and production parts.

Injection Molding

We offer low-volume prototype moldings and mass production moldings.

3D Printing

We provide 3D printing services using a range of cutting-edge additive manufacturing technologies for metal or plastic parts

What kind of industrial machinery parts can we make?

|

●Sockets

|

●Rotors

|

●Bushings

|

●Valves

|

|

|

●Jigs and fixtures

|

●Fit check gauges

|

●Automation parts

|

●Replacement parts

|

|

|

●Generator components

|

●Fasteners

|

●Hydraulic components

|

●Hydraulic components

|

|

|

●Electronic housings

|

●Pumps and accessories

|

●Turbine components and housings

|

|

|

How to get a quotation?

1. Prepare a picture or 3D drawings;

2. You want the products material;

3. Quantity per order, estimated annual requirements send to our email:

sales@gz-plastics.com , ask us TM online,

1. Prepare a picture or 3D drawings;

2. You want the products material;

3. Quantity per order, estimated annual requirements send to our email:

sales@gz-plastics.com , ask us TM online,

We can offer you quickly and give you the professional advise to save mold cost and keep

high quality.

high quality.

Our Factory

Certification

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu RoHS standard.

Application Area

PFA Product

is widely used in chemical industry, medicine, electronics, aerospace and other fields. It can be used to manufacture various products such as pipes, valves, pumps, electronic components, cable insulation layers, etc., providing important support for the development of various industries.

Our Exhibition

FAQ

Q1.

How Fast Can I Get My Parts?

A1.

We can fulfill orders quickly, but lead times depend on a few factors, such as the manufacturing process, order quantity, and part complexity. CNC machined parts can take as little as five days, 3D printed parts can take as little as three days, while moldings

made via rapid tooling can take as little as 7 days.

made via rapid tooling can take as little as 7 days.

Q2. What Is The Accuracy Of The Products Processed By The Drawings?

A2. Different equipment has different accuracy, generally between 0.05-0.1 mm.

Q3. What Craftsmanship Do You Have For Frocessing Accessories?

A3.According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q4. What Areyour Processing Equipment?

A4. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine,extruder, molding machine.

Q5. Can You Help Assembling The Product After It Is Made?

A5. It's okay .

Q6. What Certifications Or Qualifications Does Your Company Have?

A6. Our company’s certificates are:CE, ISO, ROHS, product patent certificates, etc.

Our manufacture parts to a high standard, no matter the project or the customer.

Q7. Can Injection Products Be Surface Treated? What Are The Surface Treatments?

A7. It is ok. Surface treatment: spray paint, silk screen,electroplating, etc.

Q8.

Can I Request A Sample?

For certain manufacturing processes like injection molding, we can provide a T1 sample for your parts, then further samples if required.

Q9.

I Want To Protect My IP.Are My Designs Secure?

We values privacy and security with the utmost seriousness and will happily sign a non-disclosure agreement (NDA) at your request, giving you peace of mind about your intellectual property.

Hot Searches