- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

color:

-

as clients' request

-

Name:

-

cone crusher mantle

-

Key words:

-

cone crusher spare parts

-

Certification:

-

ISO 9001: 2008

Quick Details

-

Weight (KG):

-

100

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Deya

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

color:

-

as clients' request

-

Name:

-

cone crusher mantle

-

Key words:

-

cone crusher spare parts

-

Certification:

-

ISO 9001: 2008

Contact us directly to get more information whatsapp & wechat: +86 137 2141 9876

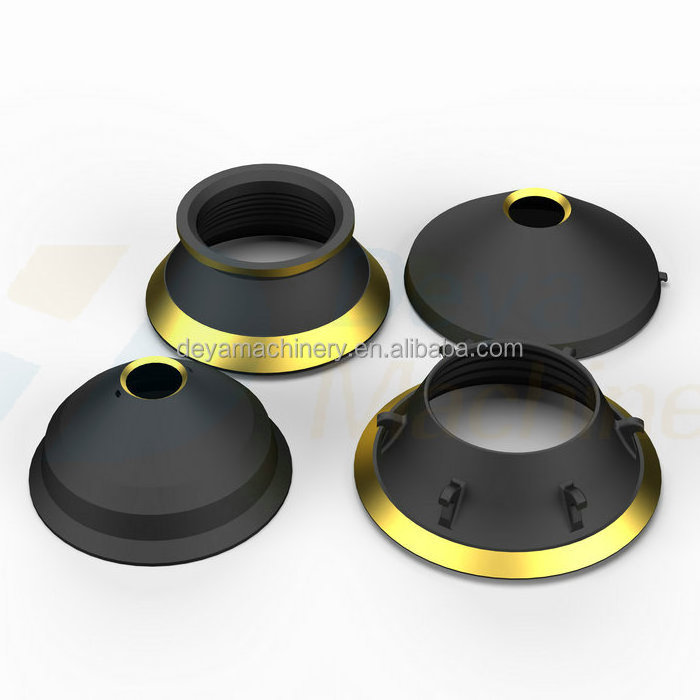

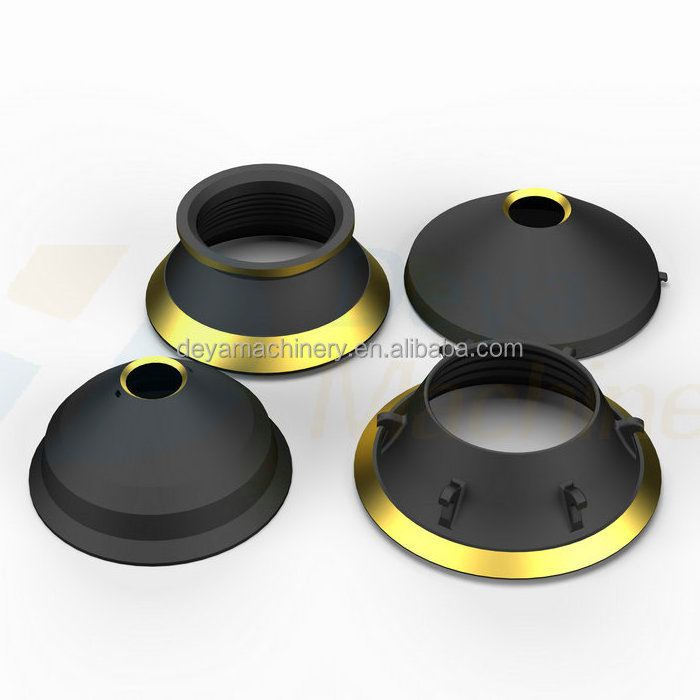

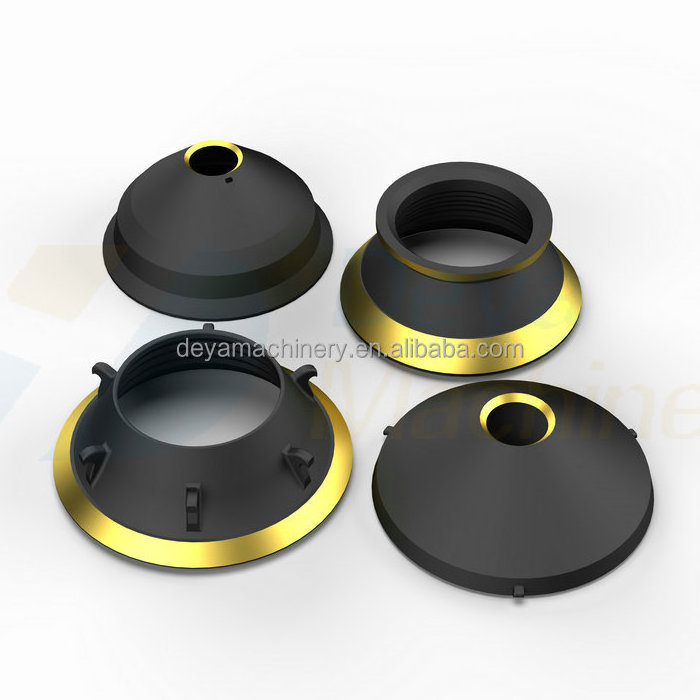

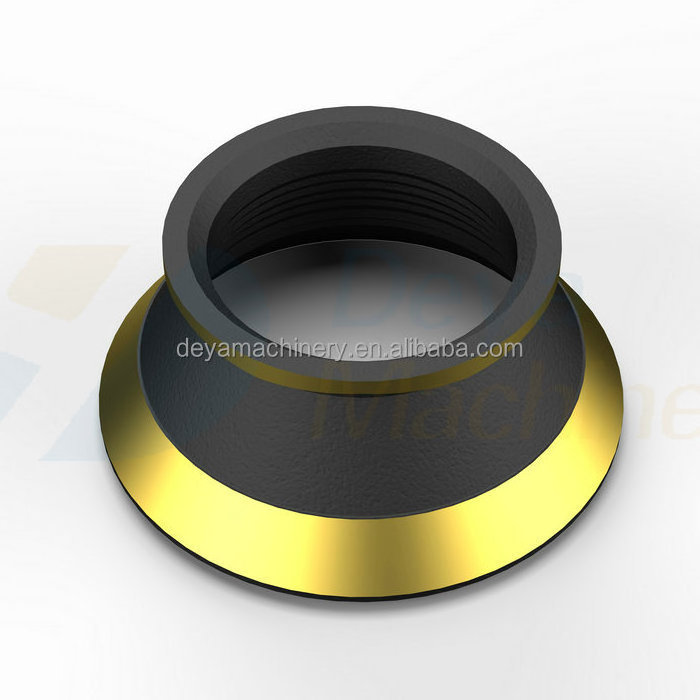

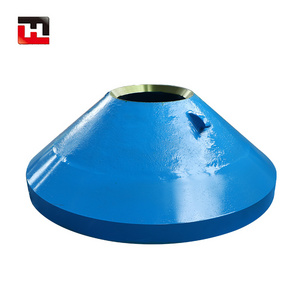

Mantle, covers the head of the crusher to protect it from wear, typical material ZGMn18Cr2 or XT710

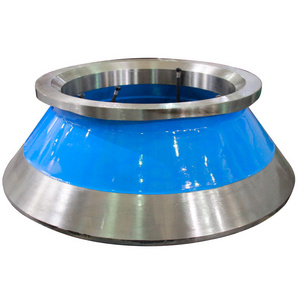

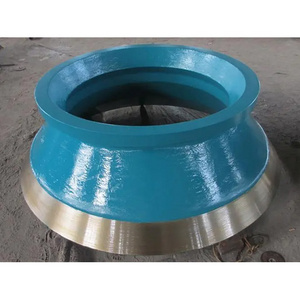

Bowl Liner, secured inside of the bowl to protect it from wear, typical material ZGMn18Cr2 or XT710

The design of Deya Machinery’s cone crusher wear parts starts with CAD and SolidWorks simulations of the cone crusher cavity, which is the heart of the crushing process.

By computer based planning and continuous quality control of the casting we can guarantee premium material quality, which translates into improved wear life and a higher operational capacity and reliability.

When change the mantle and bowl liner?

In order to prevent damage to the liner seating surfaces of the crusher head or bowl, wear parts must be replaced before they are worn through.

In normal conditions, approximately 50% of the liner weight is consumed when liners are worn out. It is important to keep a record of liner wear in order to assess the degree of liner wear without the need to stop the crusher operation.

Production considerations may sometimes favor the changing of wear parts before they are fully worn. Hourly capacity or product quality may decrease towards the end of the liner wear life, and it may be more economical to change the liner before the end of its lifetime.

Typically, distorted wear profiles can cause a reduction in capacity. Other symptoms of abnormal worn liners are high power draw and ring bounce.

Also, the wear life can be reduced because the wear is sometimes concentrated in a small zone rather than spread along the full cavity, and the cavity may have to be replaced before it is fully worn. This results in poor utilization and higher operating wear costs.

Deya Machinery supplies cone crusher mantle bowl liners, and related spares

|

Product Name

|

Cone Crusher Concave/Mantle/Bowl Liner cone crusher mantle bowl liner

|

|

Material

|

Mn13Cr2/Mn18Cr2/13%Mn/18%Mn

|

|

Hardness

|

HB 179 - 230

|

|

Standard

|

ASTM A128/A532 AS2074 H1A/ H1B

BS 3100/ BS4844 GX 130 MnCr SABS 407 Type 1 & 2 SCMnH1 GB/T 5680-2010 |

|

Production Capacity

|

Produce Parts of Unit Weight from 100KG -20,000KGS PER PIECE.

|

|

Inspection Support

|

Dimension, Chemcial Composition, Metallographic, Mechanical Character, PT/MT/UT/RT...

|