- Product Details

- {{item.text}}

Quick Details

-

Power:

-

5.5kw

-

Dimension(L*W*H):

-

2020x1120x1360mm

-

Product name:

-

Desiccant dehumidifier

-

Dehumidifying capacity:

-

34kg/h

-

Air Treatment Capacity:

-

4200m3/h

-

Air Regeneration Capacity:

-

1390m3/h

-

MOQ:

-

1 piece

-

PLC:

-

Available

-

Working Temperature Range:

-

-10+45℃

-

Automatic fault diagnosis:

-

Available

-

Steam pressure:

-

4.5±0.5kgf/cm2

-

Thickness:

-

200mm

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MSSHIMEI

-

Voltage:

-

110-130V, 220V-240V

-

Power:

-

5.5kw

-

Dimension(L*W*H):

-

2020x1120x1360mm

-

Product name:

-

Desiccant dehumidifier

-

Dehumidifying capacity:

-

34kg/h

-

Air Treatment Capacity:

-

4200m3/h

-

Air Regeneration Capacity:

-

1390m3/h

-

MOQ:

-

1 piece

-

PLC:

-

Available

-

Working Temperature Range:

-

-10+45℃

-

Automatic fault diagnosis:

-

Available

-

Steam pressure:

-

4.5±0.5kgf/cm2

-

Thickness:

-

200mm

-

Certification:

-

CE

Rotary Industrial Dehumidifier Energy Saving Low Dew Point Desiccant Dehumidifier Industrial

Why need desiccant dehumidifier

Compressor Dehumidifiers work by using refrigerant to create a cold surface and when the warm and humid air comes into contact with the cold surface, the humid air would condense into water and reduce the humidity in the air.

However, when the environment is cooler and cold, for example, under 15 °C, the cold surface would frost and force the dehumidification process to stop for defrosting.

As a result, the dehumidifying capacity is greatly reduced.

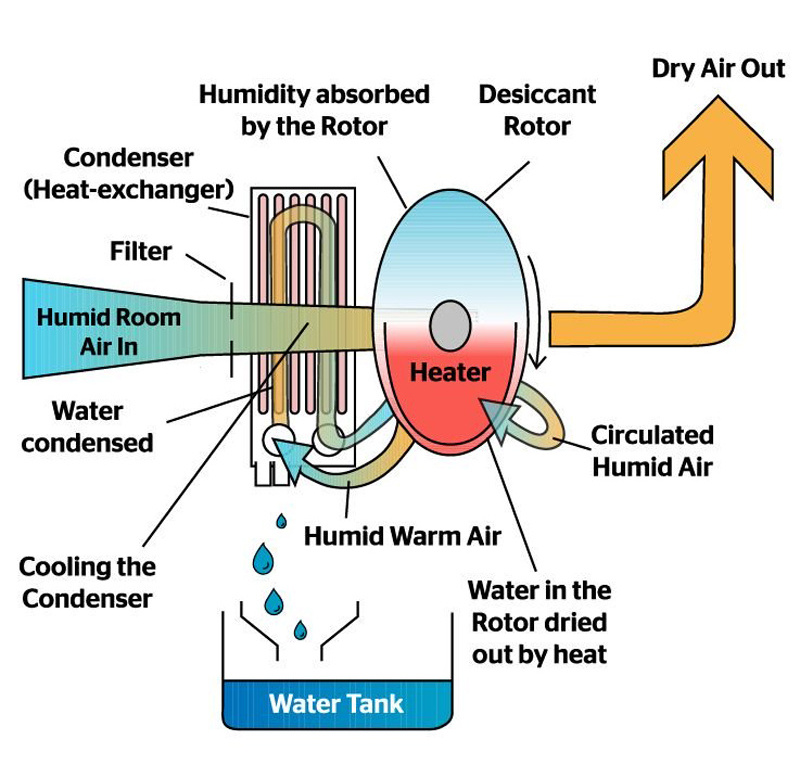

However, Desiccant Dehumidifier works differently. It uses a desiccant wheel inside to absorb the moisture in the air like a sponge, then use an internal heater to resume the dryness of the wheel.

Therefore, desiccant dehumidifier will not frost inside. On the other hand, the heating process makes the air passing through the dehumidification wheel to be warm and dry and the unit can remain high efficiency under low temperature.

How does desiccant dehumidifier work

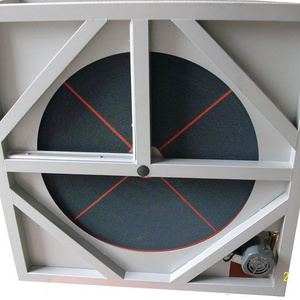

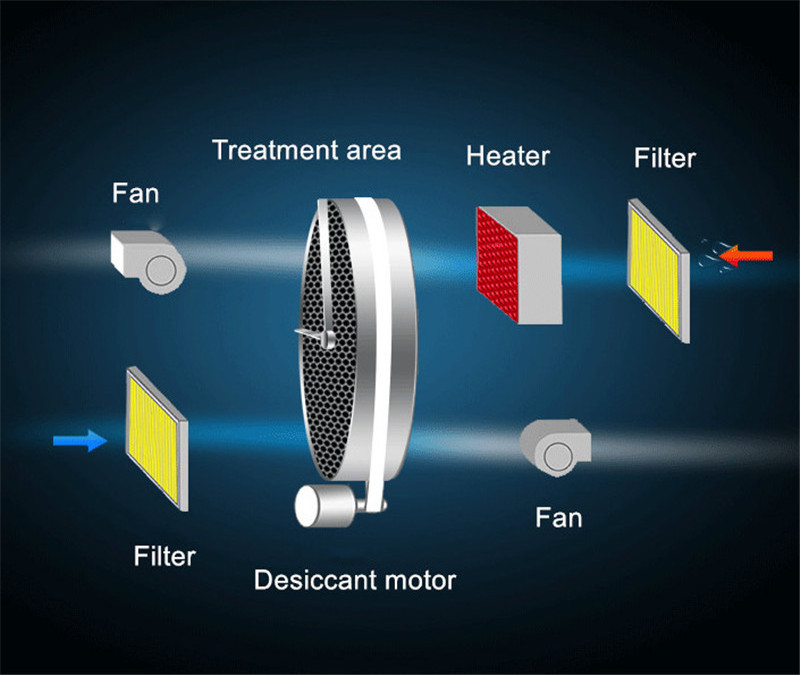

The Desiccant Dehumidifier using Sweden/USA original honeycomb type silica gel dehumidification. The cylindrical carousel is composed of a honeycomb structure, and then ceramic silica gel crystals are fired into the dehumidification zone and the regeneration zone.

The air for Rotary Dehumidification passes through the dehumidification zone, and the dry air is obtained by the runner absorbing the moisture in the air.

After absorbing moisture, the dehumidification area rotates to the regeneration area, and the regenerated heating air takes the moisture out of the runner, and the water is discharged from the outside runner.

After the moisture is discharged from the regeneration area, it is transferred back to the dehumidification area. Thus, the dehumidification and regeneration can be carried out continuously at the same time to obtain stable dry air .

Product Show

Feature

- The rotary dehumidifier is made of imported silica gel and thus has strong dehumidifying capacity and long service life.

- Dry air with super ow humidity can be easily obtained

- Its dehumidification performance is more marked under the environment of low temperature and low humidity.

- Easy to operate and management, low operating cost

- Long life and durable

- Complete equipment model, perfect dehumidification function

- Environment protection, pollution-free

Specification

Function Display

1.Highly sensitive temperature measurement control panel

2.The filter material is flame-retardant polyester non-woven fabric.Avoid unfiltered air flow filter dust particle size ≥5μm

3.Adopting Sweden/U.S. original honeycomb silicon dehumidification rotor to form a cylindrical turntable with honeycomb structure

4.Turbo centrifugal fan

Equipped with U-shaped air duct to reduce sound and noise, strong wind power greatly improves the dehumidification rate and large circulating air volume

W idely used in electronics, pharmaceutical, glass synthesis, battery, military and other industries with a required humidity of less than 45%.

1.Cutting→2.Pressing→3.Bending→4.Welding→5.Polishing→6.Pre -assembling→7.Filling→

8.Welding→9.Testing→10.A ssembling(Heating)→11.Wiring→12.Assembling(Bending)→

13.Assembling(Shell)→14.Inspecting→15.Packing