- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KAIERWO

-

Surface Finish:

-

Polishing, Painting, UV coating, electroplating

-

Material:

-

plastic and rubber

-

QC control:

-

100% inspection on critical dimension

-

Equipment:

-

OKUMA MXR-460V(f),OKUMA MXR-560VB Machinning Center etc.

-

Quantity:

-

small batch or mass production

-

Product name:

-

sla sls rapid prototype plastic case silicone mold vacuum casting

-

Processing:

-

CNC, SLA,SLS, Vacuum casting

-

Cost control:

-

most efficient production process

-

Management:

-

skilled workers and rich experienced techinicans

-

OEM/ODM:

-

Avaliable

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

OEM

-

Brand Name:

-

KAIERWO

-

Surface Finish:

-

Polishing, Painting, UV coating, electroplating

-

Material:

-

plastic and rubber

-

QC control:

-

100% inspection on critical dimension

-

Equipment:

-

OKUMA MXR-460V(f),OKUMA MXR-560VB Machinning Center etc.

-

Quantity:

-

small batch or mass production

-

Product name:

-

sla sls rapid prototype plastic case silicone mold vacuum casting

-

Processing:

-

CNC, SLA,SLS, Vacuum casting

-

Cost control:

-

most efficient production process

-

Management:

-

skilled workers and rich experienced techinicans

-

OEM/ODM:

-

Avaliable

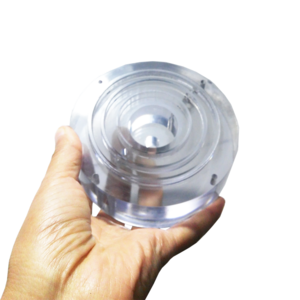

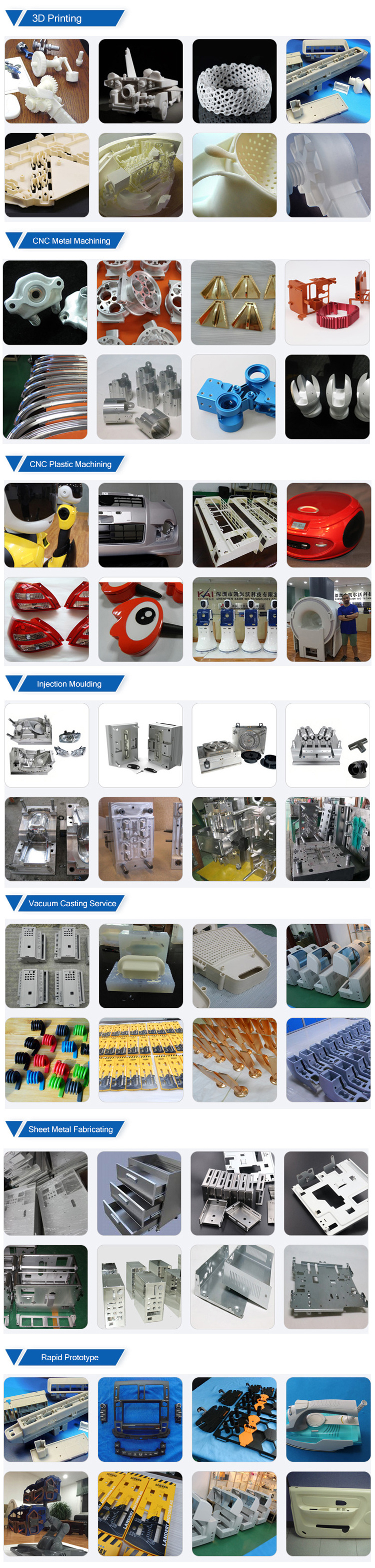

OEM Custom ABS Cnc Parts Resin Prototype Sla Sls Rapid Prototype Plastic Case Silicone Mold Vacuum Casting

|

Material Available: |

Aluminum ( Al6061, AL6063, AL7075, AL5052 , AL 6082, etc ) |

|

stainless steel ( SS201,301,303, 304, 316, 17-4PH,etc ) |

|

|

Brass ( H59 H68 H80 H90 ) |

|

|

Plastic ( ABS, PC, POM, Delrin, Nylon, PP etc. ) |

|

|

Processing: |

CNC lathe,CNC turning,CNC Milling,silicone mold ,vacuum casting ,sheet metal,3D printing service ,reacting injection mold ,rapid prototype . |

|

Surface Finish |

Electro-polish, Chrome plating, sand blasting, painting, powder coating, Vibration Grinding, Non-Stick coating ,electrophoresis etc as your choice |

|

Size & Design |

As per customized specifications in your drawings |

|

Application |

Car,Motorcycle, Bicycle, Scooter, Machinary |

|

Electronics, Furniture, Construction, |

|

|

Sport equipment,chairs,cookwares, other industrial. |

|

|

QC System |

1.Materail:Strickly control of material selection , meet international standard |

|

2.In-prosess inspection:detect product after each process finished |

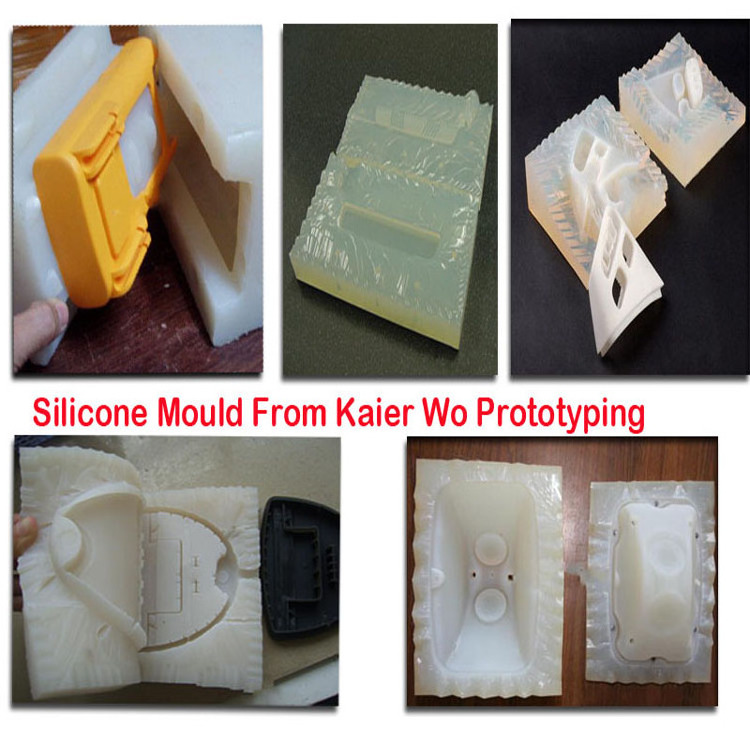

Silicone Mould & Small batch producion process

Silicone mould can be produced from the master made by the RP. After the CNC sample is sanded and polished to the surface, finished required of the part, then in turn to make the Rapid silicone mould.

Its application is mainly to produce plastics in small batch by vacuum and gravity casting method. The materials normally used are PU Epoxy. The batch size is from several pieces to over hundreds.

Color matched to Pantone or supplied sample.

Available material: ABS, PP, PC, PA (Nylon), Rubber and PMMA.

How do I get a quote?

A.Please kindly provide us 3D CAD solid model in Step,IGS,X_T format, normally Two-dimensional (2D) drawings are not adequate for accurate quoting or parts making.

B.Please tell us your requirement on quantity, surface treatment, color , material, application environment for accurate pricing.

How can I pay?

a. Bank to bank wire transfer to accounts b. Paypal c. Western Union

Will Kaier Wo sign Non-Disclosure Agreements (NDA)?

Yes. If it gives you peace-of-mind to sign an NDA, we are more than willing to do so. But we have the right to keep your design in confidential no matter NDA is signed or not. All factories are camera monitored.

What is Kaier Wo ‘s advantage?

1. 16 years abundant experience.

2.Having professional technology and high accuracy prototypes

3.Top quality and competitive price.

4. Focus on customers’ need.

Why need make rapid prototype?

Prototypes allow the design team to test for functionality and ensure design and fit is correct. The prototypes can be used for sales meetings, customer presentations, and tradeshows overall time-to-market can be reduced since accuracy in design assures a streamlined project timeline.