- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v 50Hz

-

Dimension(L*W*H):

-

4850*2150*2275mm

-

Weight (KG):

-

5450 kg

-

Core Components:

-

/

-

Use:

-

wood furniture

-

Name:

-

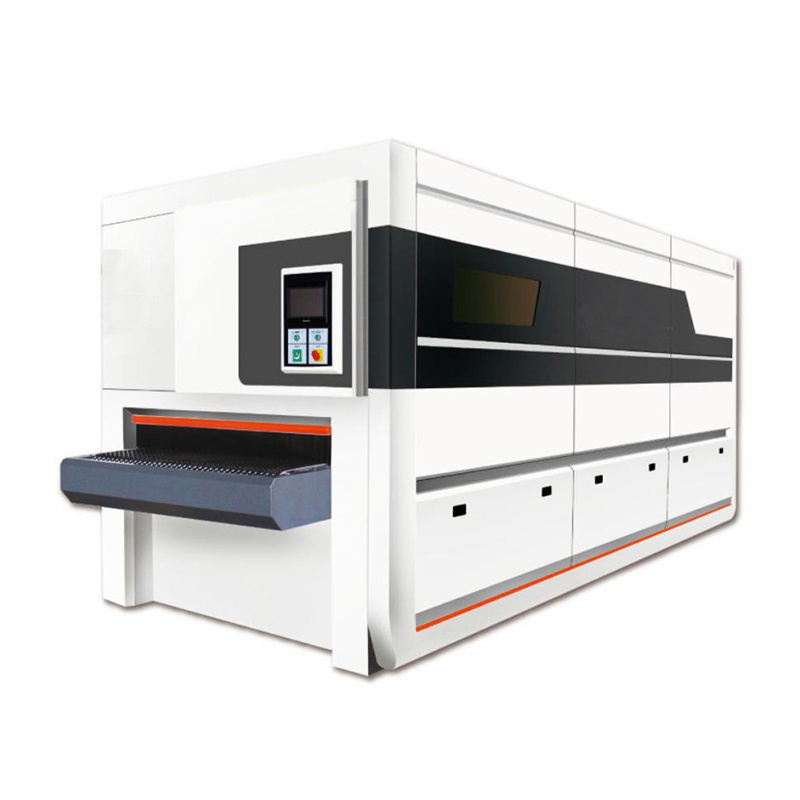

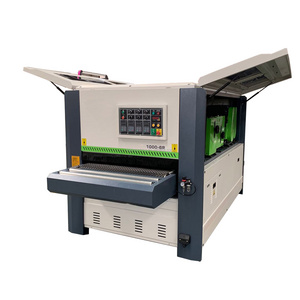

Brush Sanding Machine

-

Max Working Width:

-

1300mm

-

Working Thickness:

-

100mm

-

Feeding speed:

-

2-10m/min (Adjustable)

-

Disc brush speed:

-

80-450rpm (Adjustable)

-

Spiral roller speed:

-

80-550 rpm (Adjustable)

-

Total power:

-

18.9kw

-

Machine weight:

-

5450kg

-

Machine size:

-

4850*2150*2275mm

Quick Details

-

Place of Origin:

-

China

-

Type:

-

Brush Sanding Machine

-

Brand Name:

-

Hicas

-

Voltage:

-

380v 50Hz

-

Dimension(L*W*H):

-

4850*2150*2275mm

-

Weight (KG):

-

5450 kg

-

Core Components:

-

/

-

Use:

-

wood furniture

-

Name:

-

Brush Sanding Machine

-

Max Working Width:

-

1300mm

-

Working Thickness:

-

100mm

-

Feeding speed:

-

2-10m/min (Adjustable)

-

Disc brush speed:

-

80-450rpm (Adjustable)

-

Spiral roller speed:

-

80-550 rpm (Adjustable)

-

Total power:

-

18.9kw

-

Machine weight:

-

5450kg

-

Machine size:

-

4850*2150*2275mm

Product Description

|

Model

|

HC-G7-1300

|

|

Working width

|

Max. 1300mm

|

|

Working thickness

|

Max. 100mm

|

|

Feeding speed

|

2-10m/min (Adjustable)

|

|

Disc brush speed

|

80-450rpm (Adjustable)

|

|

Spiral roller speed

|

80-550 rpm (Adjustable)

|

|

Horizontal roller

|

330mm diameter, 2 sets * 4pc=8pc

|

|

Spiral roller quantity

|

380mm diameter, 4 sets * 1pc=4pc

|

|

Disc brush roller quantity

|

180mm diameter, 1sets * 9pc=9pc

|

|

Horizontal roller power

|

2pc*1.1kw=2.2kw

|

|

Spiral roller power

|

4pc*2.2kw=8.8kw

|

|

Disc brush roller revolution power

|

1pc*0.55kw=0.55kw

|

|

Disc brush roller self rotation power

|

1pc*1.5kw=1.5kw

|

|

Each group lifting power

|

6pc*0.25kw=1.5kw

|

|

Entirety lifting power

|

1.1kw

|

|

Feeding power

|

2.2kw

|

|

Swing power

|

6pc*0.2kw=1.2kw

|

|

Total power

|

19.8kw

|

|

Consumption power

|

6-8kw/h

|

|

Voltage

|

380v 50hz 3phase

|

|

Dust collection port

|

11pc*100mm

|

|

Dust collection speed

|

22-30m/s

|

|

Dust collection volume

|

11pc*635m3/h=6985m3/h

|

|

Dust collection device

|

Prepare by buyer

|

|

Machine size

|

4850*2150*2275mm

|

|

Weight

|

5450kg

|

Japan SEND Motor

Germany Siemens Electric appliance

Taiwan Liteon Frequency converter

Germany Continental Belt

Taiwan ZhouYi Reducer

Taiwan HIWIN Guide bearing

Details

Advantages:

* Each sanding unit can be adjusted independently, and can be fine-tuned according to the product process to ensure the maximum combination of abrasive and workpiece, which can significantly improve the grinding effect. Strengthen the independent lifting mechanism to make the grinding process more stable.

* Each sanding unit can independently adjust the speed, effectively improve the quality of grinding, prevent damage to the shape and paint leakage.

* Each sanding unit cooperates with swing system to make the grinding range wider and more uniform, and effectively avoid scratches caused by long grinding.

* Each sanding unit is equipped with a human-designed drawing system, which makes it easier to replace consumables.

* Each group of sanding units with thickness display function, the operation is more intuitive , convenient (Note:This model can choose memory function).

* Large diameter sanding roller structure , matched with high quality sand paper , mexico sisal, softer and flexible, and it is easier to sand the complex design products.

* Each sanding unit is removable .This structure is more portable to replace the sanding paper or sanding part and it is easier to sand the complex design products and it is convenient for maintenance.

* Brush disc adopts the high speed disassembly structure , effectively shortens the replacement time of the sand paper, which is faster and more efficient than the traditional structure

* Each sanding unit can be adjusted independently, and can be fine-tuned according to the product process to ensure the maximum combination of abrasive and workpiece, which can significantly improve the grinding effect. Strengthen the independent lifting mechanism to make the grinding process more stable.

* Each sanding unit can independently adjust the speed, effectively improve the quality of grinding, prevent damage to the shape and paint leakage.

* Each sanding unit cooperates with swing system to make the grinding range wider and more uniform, and effectively avoid scratches caused by long grinding.

* Each sanding unit is equipped with a human-designed drawing system, which makes it easier to replace consumables.

* Each group of sanding units with thickness display function, the operation is more intuitive , convenient (Note:This model can choose memory function).

* Large diameter sanding roller structure , matched with high quality sand paper , mexico sisal, softer and flexible, and it is easier to sand the complex design products.

* Each sanding unit is removable .This structure is more portable to replace the sanding paper or sanding part and it is easier to sand the complex design products and it is convenient for maintenance.

* Brush disc adopts the high speed disassembly structure , effectively shortens the replacement time of the sand paper, which is faster and more efficient than the traditional structure

The structure adopts left and right rolls + 360 degree discs+front and rear roller

The sandpaper is more fully polished from coarse to fine,and the sanding effect can be more than 90%.

The same abrasive belt can be used as unpainted wood and painted wood .

The 1st and 2nd sanding rollers can be oscillated to the left and right to ensure polishing effect,and the hollowing plate can be polished to 3-5 mm.

The diameter of the roller is 350mm,which is softer and thicker,making the contact surface easier to polish.

Disk Technology Upgrade

4th & 5th sanding units are rotary discs.These are our company's innovative design with national patents. Large discs drives small discs,it can achieve no dead corner polishing.

Especially it has a good polishing effect on grooves. Besides,these discs adopts quick disassembley technology.

Spiral Roller Technology Upgrade

The 3rd, 6th and ,7th,8th,9th sanding units adopt spiral rollers to finish the whole rough and fine sanding .It can sand from front to back and from back to front.

The spiral rollers are equipped with different sandpapers and they have different sanding rotation directions.

Height Display + Independent Up and Down

The sanding depth of each sanding unit can be adjusted independently. This can greatly improve the sanding effect. Independent lifting structure makes the sanding process more stable.And there is sanding display for the sanding depth,it makes the operation more visual.

(Note:G7 and G9 model can choose memory function,so that you don’t need to adjust it each time for different workpieces).

With memory function,it can automatically adjust the grinding speed of different plates.

Final Product

Company Introduction

Our Company:

HICAS group is one leading manufacturing and exporting company of wood working machine in China. We are committed to provide

one-stop service to our customers all over the world.

HICAS was established in 2003 with two manufacturing centers in Foshan and Qingdao, covering about 40,000 square meter.

1.Founded in 2003.

2.Owns 2 factories manufacturing nailess plywood box machine, wood pallet machine,wood crate machine, nailless plywood box.

3.Owns 70% Market Share(Nailless plywood box machine) in China.

4.Expertized in R&D, Manufacturing, Marketing,Training, and Service.

5.Professional in consultation of Factory construction and Processing Technology, and Technical Improvement Training.

6.Supply Technical Solution base on Cost Analysis and Optimal Allocation.

7.Customer and feedback

HICAS group is one leading manufacturing and exporting company of wood working machine in China. We are committed to provide

one-stop service to our customers all over the world.

HICAS was established in 2003 with two manufacturing centers in Foshan and Qingdao, covering about 40,000 square meter.

1.Founded in 2003.

2.Owns 2 factories manufacturing nailess plywood box machine, wood pallet machine,wood crate machine, nailless plywood box.

3.Owns 70% Market Share(Nailless plywood box machine) in China.

4.Expertized in R&D, Manufacturing, Marketing,Training, and Service.

5.Professional in consultation of Factory construction and Processing Technology, and Technical Improvement Training.

6.Supply Technical Solution base on Cost Analysis and Optimal Allocation.

7.Customer and feedback

8. Our company and products have been verified onsite by SGS Group

9. Our mission and target.

Let Chinese woodworking machinery serve the whole world.

Make our staff realize financial freedom.

Create maximum value for customers.

To be the biggest woodworking machinery exporter in China.

Let Chinese woodworking machinery serve the whole world.

Make our staff realize financial freedom.

Create maximum value for customers.

To be the biggest woodworking machinery exporter in China.

Hot Searches