- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

44

-

Name:

-

Wood Sawdust Block Making Machine

-

Application:

-

Wood Working

-

After-sales Service Provided:

-

Spare Parts and installation

-

Product name:

-

Multiused Woodworking Machine

-

Usage:

-

Woodworking Equipment

-

Keywords:

-

Easy Operation

-

Function:

-

Produce Molded Pallets

-

Raw material:

-

Wood Waste

-

Type:

-

Full-automatic

-

Key words:

-

Wood Processing Equipment

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

zhongke

-

Weight (KG):

-

2000 KG

-

Power (kW):

-

44

-

Name:

-

Wood Sawdust Block Making Machine

-

Application:

-

Wood Working

-

After-sales Service Provided:

-

Spare Parts and installation

-

Product name:

-

Multiused Woodworking Machine

-

Usage:

-

Woodworking Equipment

-

Keywords:

-

Easy Operation

-

Function:

-

Produce Molded Pallets

-

Raw material:

-

Wood Waste

-

Type:

-

Full-automatic

-

Key words:

-

Wood Processing Equipment

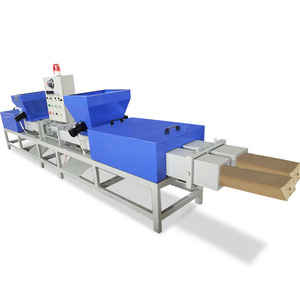

The wooden pier hot press machine produced by our company is of advanced quality. The surface of the wooden pier pallet feet produced is smooth and flat, with good waterproof performance (no cracking after soaking in water for 48 hours, no cracking under wind and sun), and strong nailing force.

Molds can be customized according to the specifications and sizes required by customers. The products made are exempt from inspection and fumigation for export, and the formaldehyde emission (E2) is in line with national standards. The internal bonding strength reaches 1.07mpa.

The screw holding force is 1590N vertically and 1660N parallel. It is an ideal material for making fumigation-free wooden pallet supports (foot piers, frame legs). It is mainly used to replace the foot piers used on log pallets, free of fumigation,

Free from heat treatment.

The structure of the equipment is simple, the operation is convenient, the pier products produced are clean and environmentally friendly, the market prospect is broad, and it is in line with the national industrial development policy.

The first choice for investing in setting up factories and starting businesses. The investment in this equipment is less than one-third of that of ordinary press machines. Due to the different production process principles, the gloss and water resistance of the products produced are better than that of thick shavings and sawdust boards.

The sawdust foot piers are incomparable.

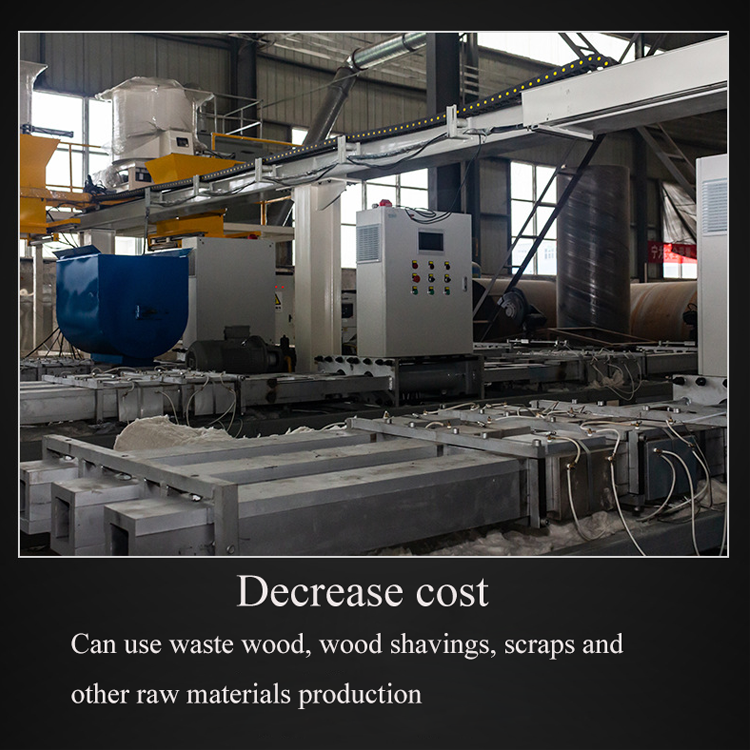

The wooden pier machine generally uses waste such as shavings, sawdust, rotten wood boards, and branches as raw materials. The raw materials are first screened and classified to prevent the machine from being damaged due to hard debris such as metal in the raw materials.

Then it is pulverized by a pulverizer (when the raw material is less than 5*5mm, it does not need to be pulverized), it is dried in a dryer, glued by a glue mixer, and then hydraulically formed by a hot press abrasive tool, and extruded into a wooden pier product.

Cut into small square products required by customers.

| Model | ZKB-2 | ZKB-4 | ZKB-6 |

| Size(mm) | 4800x780x1320 | 4800x780x1320 | 4800x900x1420 |

| Size of block (mm) | 75-145 | 75-145 | 75-100 |

| power(kw) | 27.2 | 35.4 | 44.1 |

| Density (kg/m3) | 550-600 | 550-600 | 550-600 |

| capacity (m3/h) | 2-5 | 3-6 | 5-9 |

| Dimension with saw(mm) | 8000x600x1500 | 8000x700x1500 | 8000x700x1500 |

| Weight(kg) | 1000 | 1500 | 2000 |

| Block size usually width 75-145mm,length 75-145mm can also be customized | |||

Raw material

Raw material

FFinal product

FFinal product