- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

P10-7

-

Working Pressure:

-

Please contact us for details

-

Machinery Test Report:

-

Please contact us for details

-

Video outgoing-inspection:

-

Please contact us for details

-

Marketing Type:

-

Please contact us for details

-

Warranty of core components:

-

Please contact us for details

-

Core Components:

-

Please contact us for details

Quick Details

-

Applicable Industries:

-

Please contact us for details

-

Place of Origin:

-

Japan

-

Brand Name:

-

JCC

-

Model Number:

-

P10-7

-

Working Pressure:

-

Please contact us for details

-

Machinery Test Report:

-

Please contact us for details

-

Video outgoing-inspection:

-

Please contact us for details

-

Marketing Type:

-

Please contact us for details

-

Warranty of core components:

-

Please contact us for details

-

Core Components:

-

Please contact us for details

Products Description

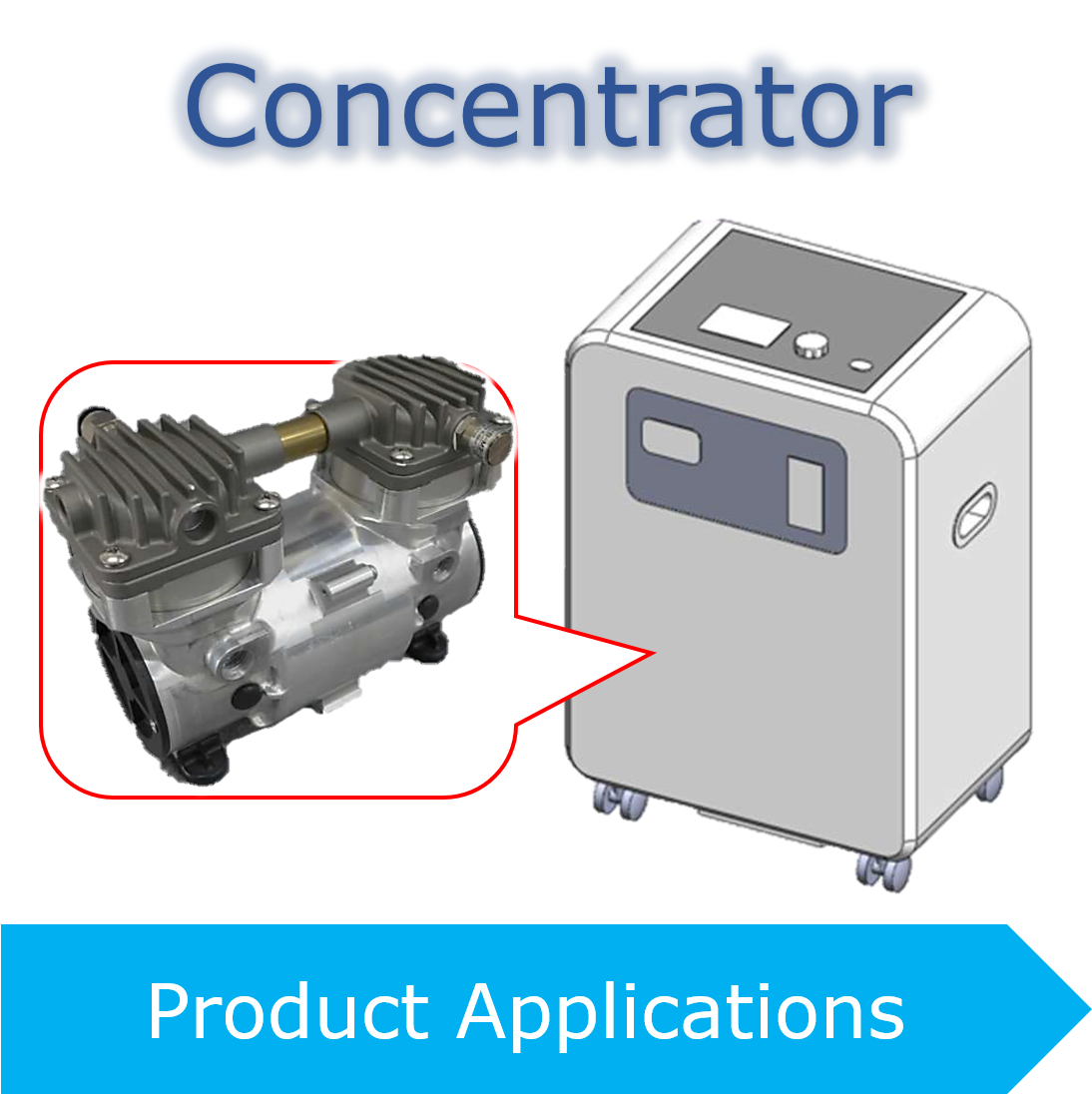

Product Applications

Oxygen Concentrator

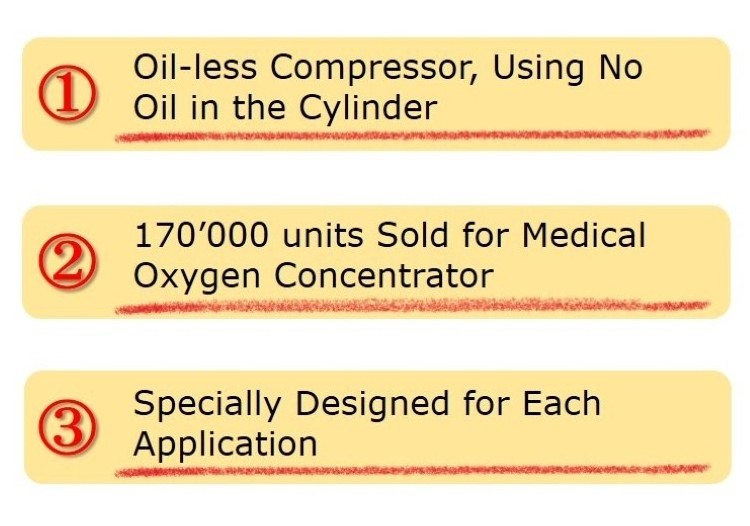

Used as a compressor for oxygen concentrator for those who have lung diseases and need home treatment.

The rapid increase in the number of pulmonary patients due to COVID-19, has increased the demand for oxygen concentrators, while compressors are widely used in various fields.

Since production stared in 2004, more than 170,000 units have been sold.

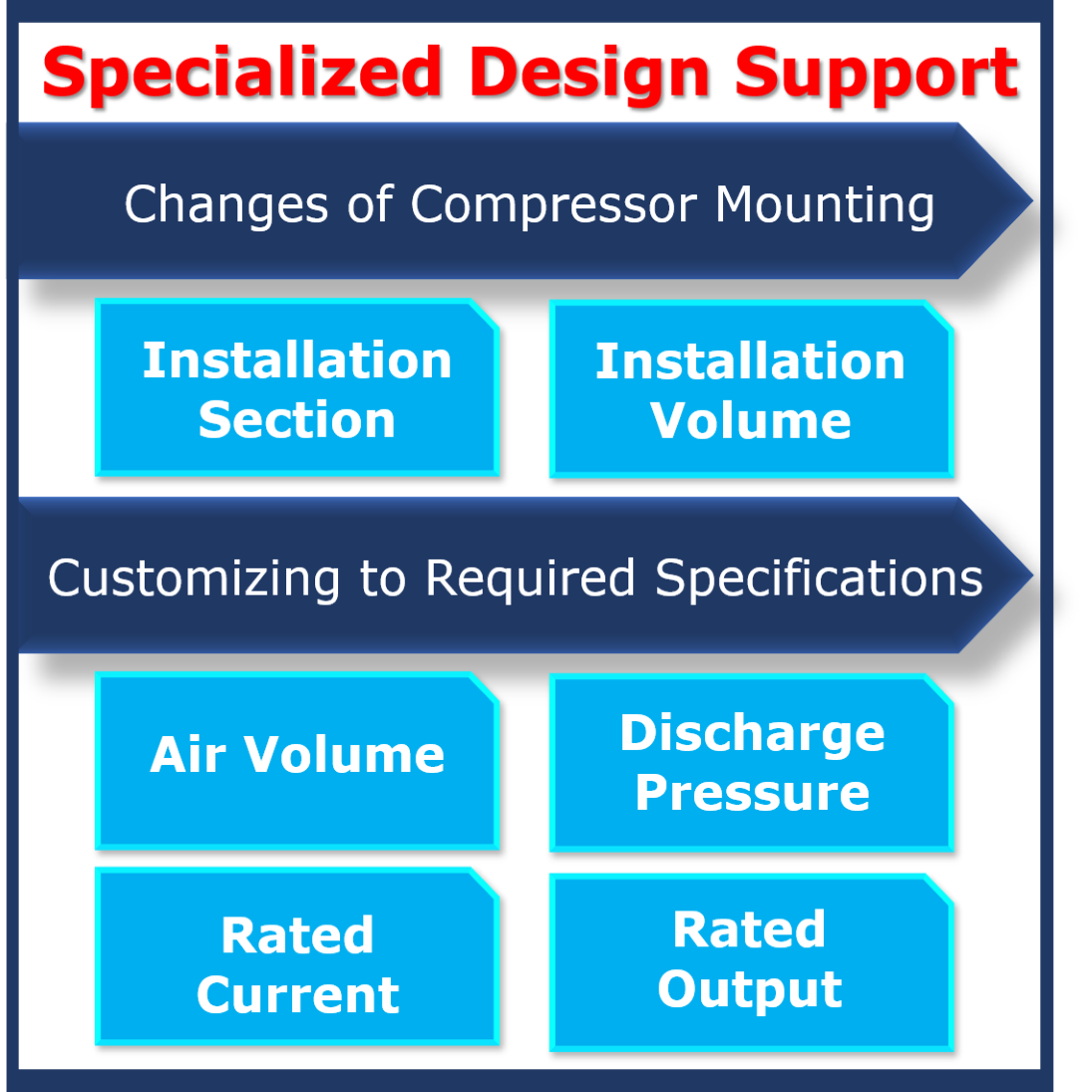

We develop, design, and manufacture compressors which meet customer requirements with dedicated design supports.

Product Processing

Our machining processes include cutting, shaft cutting, press working, welding, and resin molding.

Our machining with CNC lathes and machining center enables high-precision process by using special jigs for parts.

According to the number of units required and the specifications, the production system is arranged by line, batch or cell.

Quality Control

Machining accuracy is controlled by 3D measuring instrument, surface roughness measuring instruments, roundness measuring machine, projector measuring instruments (image measurement).

Electric current test and characteristic test with ventilation are conducted to all finished products. All test results are recorded electronically in our management system.

Conducting various tests which include performance, leakage and insulation withstand voltage, then after the final inspections, barcodes and product nameplates are generated only to the product inspected, so that no product is shipped out without passing the inspections.

In addition to 100% inspection, all products go through random inspection by each production lot for performance, characteristics, screw tightening torque, and then shipped out under strict quality control.

|

Specifications

|

|

|

||

|

Series

|

ACP-171

|

ACP-121

|

||

|

Model

|

2 piston reciprocating compressor

|

2 piston reciprocating compressor

|

||

|

Pressure

|

160 kPa

|

120 kPa

|

||

|

Flow Rate

|

60 L/min

|

50 L/min

|

||

|

Output

|

170 W

|

135 W

|

||

|

Power Consumption

|

260 W

|

195 W

|

||

|

Power

|

AV100V(Primary)

|

AV100V(Primary)

|

||

|

Suction Diameter

|

Φ12 mm

|

Φ12 mm

|

||

|

Discharge Diameter

|

Φ12 mm

|

Φ12 mm

|

||

|

Dimension

|

D99mm×W182mm×H150mm

|

D99mm×W186mm×H144mm

|

||

|

Weight

|

3.6 kg

|

2.8 kg

|

||

|

Please contact us for quantity, delivery time, price, specification change, packing specification, etc. in details.

|

|

|

||

Product Usage

"Air Compressor" are used by medical equipment manufacturers for air blowing and pneumatic pressure.

They are compact and lightweight, yet making high efficient air supply, used as built-in pneumatic control equipment.

Recommend Products

Hot Searches