- Product Details

- {{item.text}}

Quick Details

-

Wind Load:

-

60M/s

-

Snow Load:

-

1.5KN/m2

-

Warranty:

-

10 Years

-

Product name:

-

Solar Ground Mounting System

-

Color:

-

Silver

-

Material:

-

Q355B Steel

-

Application:

-

PV Solar Panel Installation

-

Mounting Type:

-

Ground Solar Mounting System

-

Service life:

-

25YRS

-

Engineering Service:

-

Engineering Service

-

Certificate:

-

CE/ISO9001

-

Advantages:

-

Customized Service Provided

-

Our Service:

-

Professional Customization Services

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jiudingli

-

Model Number:

-

Solar Ground Mounting System

-

Wind Load:

-

60M/s

-

Snow Load:

-

1.5KN/m2

-

Warranty:

-

10 Years

-

Product name:

-

Solar Ground Mounting System

-

Color:

-

Silver

-

Material:

-

Q355B Steel

-

Application:

-

PV Solar Panel Installation

-

Mounting Type:

-

Ground Solar Mounting System

-

Service life:

-

25YRS

-

Engineering Service:

-

Engineering Service

-

Certificate:

-

CE/ISO9001

-

Advantages:

-

Customized Service Provided

-

Our Service:

-

Professional Customization Services

Products Description

Solar Ground Mounting System

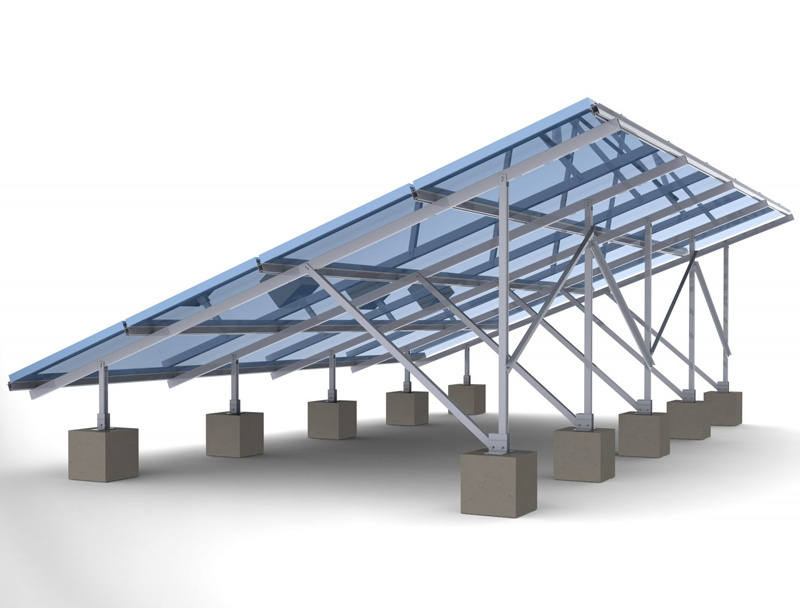

Solar Ground Mounting System The structure of photovoltaic support usually includes columns, main beams, purlins, welds and foundation components. It can be customized according to different sizes and shapes of photovoltaic modules to meet the installation needs of different environments. There are a wide variety of materials available for photovoltaic brackets, including aluminum alloys, hot dip galvanized and zinc-aluminum-magnesium. The selection of these materials usually depends on the local climatic conditions and geological characteristics.

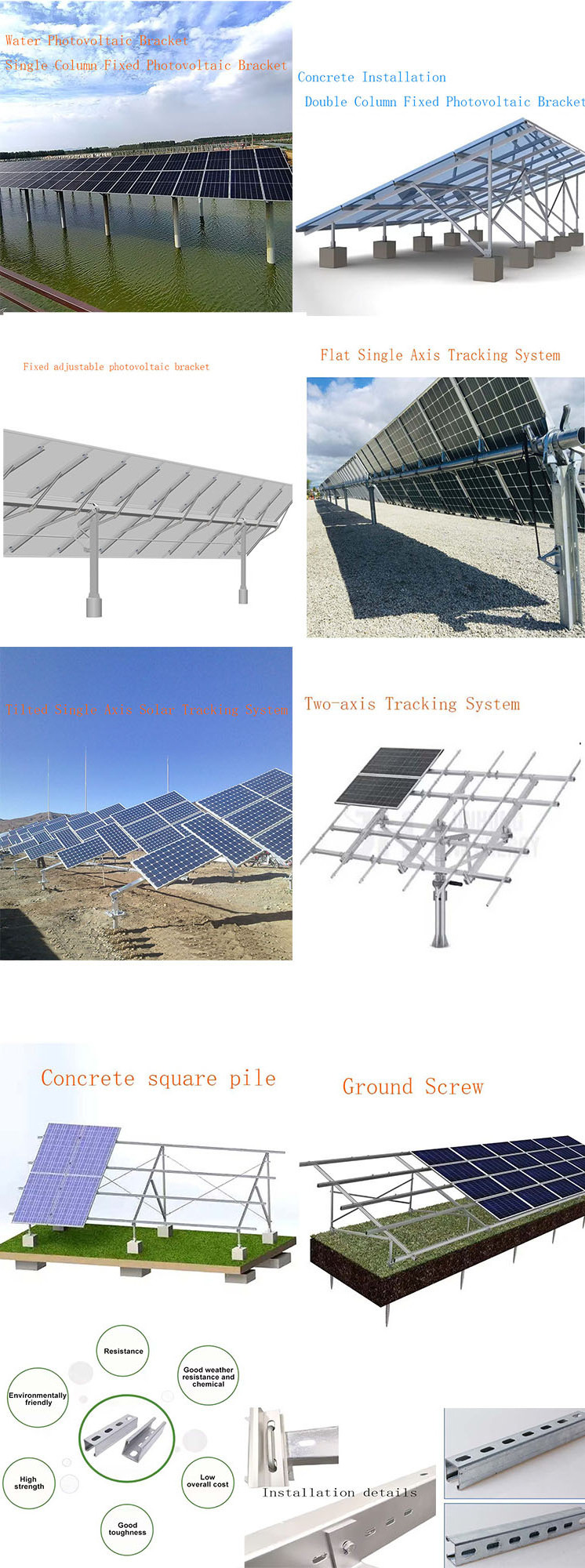

The main categories of photovoltaic brackets include fixed brackets and tracking brackets. The fixed bracket is divided into two kinds of fixed brackets that can be adjusted and cannot be adjusted. The fixed photovoltaic bracket is divided into single column bracket and double column bracket. The tracking bracket can be automatically adjusted mechanically or electronically to track the movement of the sun. The tracking brackets are available in flat single-axis tracking, oblique single-axis tracking and two-axis tracking brackets that can be adjusted in multiple directions to capture solar energy more efficiently.

Photovoltaic brackets have a wide range of application scenarios and can be installed on the ground or in other specific environments.

The main categories of photovoltaic brackets include fixed brackets and tracking brackets. The fixed bracket is divided into two kinds of fixed brackets that can be adjusted and cannot be adjusted. The fixed photovoltaic bracket is divided into single column bracket and double column bracket. The tracking bracket can be automatically adjusted mechanically or electronically to track the movement of the sun. The tracking brackets are available in flat single-axis tracking, oblique single-axis tracking and two-axis tracking brackets that can be adjusted in multiple directions to capture solar energy more efficiently.

Photovoltaic brackets have a wide range of application scenarios and can be installed on the ground or in other specific environments.

|

Product name

|

Solar Ground Mounting System

|

|

Surface

|

Solar Ground Mounting System

|

|

Certificate

|

CE/ISO9001

|

|

Advantages

|

Customized Service Provided

|

|

Service life

|

25YRS

|

|

Service life

|

Engineering

|

|

Our Service

|

Professional Customization Services

|

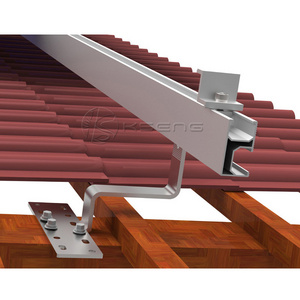

Installation Instructions

Details Images

|

Ground support foundation

|

setting

|

feature

|

range of application

|

|

Cement Base

|

|

The depth of the foundation can be relatively shallow, but the amount of excavation and backfill is large, and the amount of

concrete is relatively large. |

This kind of foundation form is mostly used in poor foundation bearing capacity, suitable for flat single-axis tracking

photovoltaic brackets with relatively flat sites and low groundwater levels, and high requirements for uneven settlement. |

|

Precast pile foundation

|

Prefabricated pile is made in the factory or construction site of various materials, various forms of pile (such as wooden pile,

concrete square pile, prestressed concrete pipe pile, steel pile, etc.), the pile is driven, pressed or vibrated into the earth with pile driving equipment. Precast piles are mainly concrete precast piles and steel piles in the construction field of China. |

It can be made in batch, the construction speed is fast, the construction does not exist to fill the excavation, only a simple

field level. However, when the pile body is squeezed into the soil by static pressure or hammer equipment, the pile body is easy to fracture, and the top of the pile needs to be reinforced by steel mesh, which increases the cost and the perpendicularity is not easy to ensure. |

It is widely used in silty soil, cohesive soil, fill soil, collapsible

loess and so on. |

|

Hammer the pile into the ground

|

The use of a pile driver to directly drive C-shaped steel, H-shaped steel or other structural steel into the ground, this

installation method is very simple, but the tensile performance is poor. |

Fast speed, strong adaptability;

High cost performance; Not subject to seasonal temperature and other restrictions; The ground pile removal is convenient and does not affect the reuse of the installation site. |

It is difficult to drive piles in hard soil; It is easy to destroy the galvanized layer when driving pile in the area with more gravel. Corrosion resistance is poor in saline-alkali areas. |

|

Ground Screw

|

After the 1880s, screw pile has been widely used in the United States, Australia and Europe as an alternative pile with unique

advantages, which can meet various engineering requirements such as compression, withdrawal and horizontal force resistance. |

The utility model relates to a pipe pile or pile of metal or non-metal materials with spiral blades, which is screwed into the

ground by special equipment, and the top of the pile is connected to the load. The utility model has the advantages of fast and convenient construction, greatly shortening the construction period. |

|

The structure, classification and application of photovoltaic support:

The structure of photovoltaic support usually includes columns, main beams, purlins, welding parts and foundation components. They can be customized according to the different sizes and shapes of photovoltaic modules to meet the installation needs of different environments. There is a wide variety of materials available for photovoltaic supports, including but not limited to aluminum alloy, steel and concrete. The selection of these materials usually depends on the local climatic conditions and geological characteristics.

The main categories of photovoltaic brackets include fixed brackets and tracking brackets. The fixed bracket cannot be adjusted for Angle, while the tracking bracket can be automatically adjusted mechanically or electronically to track the sun's movement. In addition, there are special bracket types, such as single-axis and dual-axis tracking brackets, which can be adjusted in multiple directions for more efficient solar energy capture.

Photovoltaic supports have a wide range of application scenarios, which can be used on the roof of a building, or installed on the ground or in other specific environments. They are not only suitable for domestic and commercial photovoltaic power plants, but also for special applications in agricultural photovoltaic systems, maritime and highway lighting. With the advancement of technology, the design of photovoltaic brackets is also constantly optimized to improve its performance and economy.

Product Paramenters

Hot Searches