- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

N/A

-

Place of Origin:

-

China

-

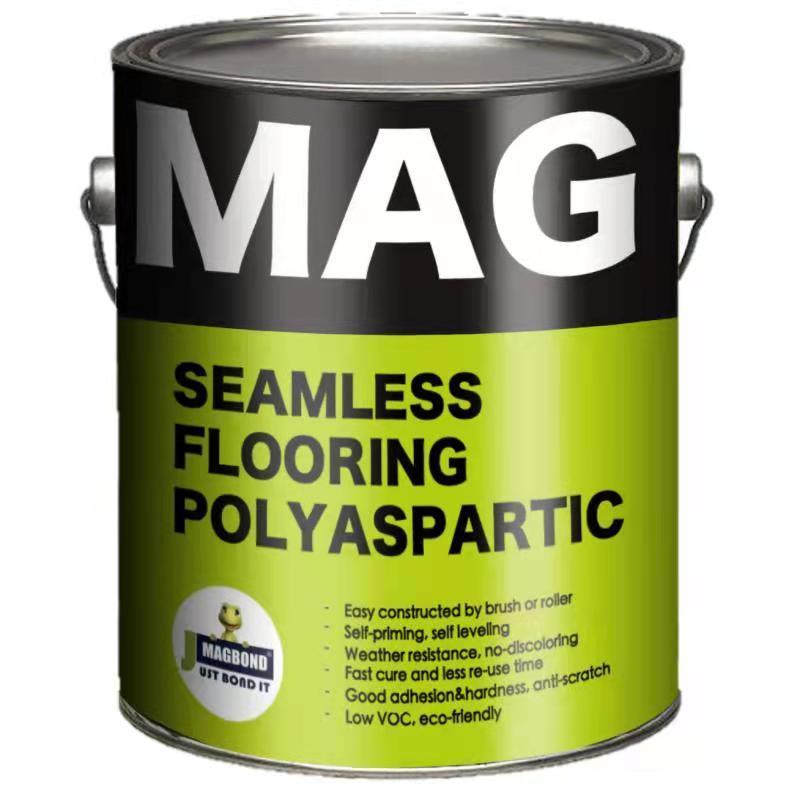

Brand Name:

-

MAGBOND

-

Model Number:

-

ASP100

-

Type:

-

Polyaspartic flake flooring

-

Product name:

-

Swimming Pool Coating

-

Material:

-

Polyaspartic polyurea

-

Feature:

-

1. Eco-friendly, non-toxic, high safety in use

-

Application:

-

all floor coating

-

Package:

-

20kg/barrel

-

Color:

-

optional

-

Advantage:

-

non-yellowing and waterproof

-

OEM:

-

Avalialbe

-

Appearance:

-

clear/colored per request

-

Certificate:

-

France A+/ ISO9001 /UKCA

Quick Details

-

CAS No.:

-

136210-30-5

-

Other Names:

-

Polyaspartic Flake Flooring

-

MF:

-

N/A

-

EINECS No.:

-

N/A

-

Place of Origin:

-

China

-

Brand Name:

-

MAGBOND

-

Model Number:

-

ASP100

-

Type:

-

Polyaspartic flake flooring

-

Product name:

-

Swimming Pool Coating

-

Material:

-

Polyaspartic polyurea

-

Feature:

-

1. Eco-friendly, non-toxic, high safety in use

-

Application:

-

all floor coating

-

Package:

-

20kg/barrel

-

Color:

-

optional

-

Advantage:

-

non-yellowing and waterproof

-

OEM:

-

Avalialbe

-

Appearance:

-

clear/colored per request

-

Certificate:

-

France A+/ ISO9001 /UKCA

Product Description

Polyaspartic Flake Flooring Topcoat

is mainly designed to be used in occasions with high decorative requirements, such as commerciial imitation PVC floors and colored sand floors. It's a two-component varnish, cured by aspartate resin and aliphatic isocyanate. It's of high solids, non-toxic, and eco-friendly. It has good compressive strength, good wear resistance and impact resistance, and it's non-yellowing, UV resistant.

Physical parameters

|

Main agent

|

Curing agent

|

|

Appearance: colorless transparent liquid

|

Appearance: all colors liquid

|

|

Viscosity 25℃: 400MPaS

|

Viscosity 25℃: 100MPaS

|

|

Specific gravity 25℃:1.02

|

Specific gravity 25℃:1.01

|

|

Solids: 99%

|

Solids: 64%

|

|

Material properties after curing

|

|

|

|

Paint appearance

|

normal

|

|

|

7 days hardness

|

shore D 68

|

|

|

Abrasion (CS17 wheel 750g, 500rpm)

|

25mg

|

|

|

Elongation at break (%)

|

15

|

|

|

Tensile strength (MPa)

|

23

|

|

|

Concrete adhesion (Mpa)

|

2.2

|

|

|

Impact resistance (1000g, 1m)

|

Pass

|

|

Construction Parameters:

Use ratio:

Roll coating: A: B = 1:1 mass ratio

Construction conditions:

Ambient temperature: 0℃-35 ℃, Ambient humidity: ≤85%

Substrate temperature: must be greater than the air dew point temperature 3 ℃ or more.

Cleaning agent: polyaspartic polyurea standard thinner

The above data is for guidance only. The actual drying time/interval time before coating can be longer or shorter depending on the film thickness of the coating, ventilation condition, temperature and humidity, etc.

Surface Treatment:

⚫Rinse off salt and other water-soluble dirt with water

⚫ Remove grease and oil with appropriate cleaners and degreasers

⚫ Concrete substrate must be ground and cleaned thoroughly

⚫ Pay attention to the coating interval with the primer during construction

Storage:

Storage time: Paint: 1 year Curing agent: 9 months

Storage temperature: 5℃-35℃

Packaging Specification:

Paint: 20KG Curing agent: 10KG

Security Measures:

⚫ Avoid contact with skin and eyes.

⚫ If the paint comes in contact with the skin, it should be cleaned with an appropriate cleaning agent. If paint comes into contact with eyes, use plenty of water to flush and seek immediate medical attention.

⚫ Ensure good ventilation.

⚫ The paint contains combustible substances. Please keep away from sparks and do not smoke in the adjacent work area.

⚫ Comply with all health and safety regulations on site.

Statement:

The information provided in this product specification is based solely on our knowledge gained in the laboratory and in practice. However, since use of the product is usually beyond our control, so we only give a guarantee of the quality of the product itself. We reserve the right to amend the specification by prior notice.

CASE SHOW

Eco-friendly, non-toxic, high safety in use

High impact and wear resistant, freeze-thaw resistant, strong environmental adaptability

Bright colors, strong decoration, durable

Painting process

1 Closed primer

2 Polyaspartic polyurea leveling mortar layer

3 Polyaspartic polyurea middle coating

4 Polyaspartic polyurea topcoat

5 Polyaspartic polyurea anti-slip layer

Packing & Delivery

Hot Searches