1. Can be used as flat bag / stand-up bag

2. Can add suction nozzle, compatible with zipper

3. Adjustable bag size range

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

850

-

Voltage:

-

380v

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

UVANPACK

-

Dimension(L*W*H):

-

1645*1450*1455mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

material:

-

stainless steel

-

pouch:

-

pre-made pouch

-

pouch type:

-

stand up pouch/4 side sealed /3 side sealed

-

Model:

-

YFG8-200

-

Keyword:

-

Rotary filling and sealing

-

Usage:

-

widely used

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE

Quick Details

-

Function:

-

FILLING, Sealing

-

Packaging Type:

-

Bags, Film, Pouch, Stand-up Pouch

-

Packaging Material:

-

Plastic

-

Weight (KG):

-

850

-

Voltage:

-

380v

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

UVANPACK

-

Dimension(L*W*H):

-

1645*1450*1455mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

material:

-

stainless steel

-

pouch:

-

pre-made pouch

-

pouch type:

-

stand up pouch/4 side sealed /3 side sealed

-

Model:

-

YFG8-200

-

Keyword:

-

Rotary filling and sealing

-

Usage:

-

widely used

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE

Product Overview

Machine Application

YFG-210 premade pouch packaging machine for doypack pouch,flat pouch is suitable for premade pouches filling packing.

YFG-210 packaging machine can complete pouch feeding, measuring, filling, sealing, date printing, nitrogen filling, counting, and finished product delivery. It is suitable for filling different products such as powder, granule, liquid, cream and other non free-flowing liquid when equipped with feeding and measuring devices.

YFG-210 premade pouch packaging machine for doypack pouch,flat pouch is suitable for premade pouches filling packing.

YFG-210 packaging machine can complete pouch feeding, measuring, filling, sealing, date printing, nitrogen filling, counting, and finished product delivery. It is suitable for filling different products such as powder, granule, liquid, cream and other non free-flowing liquid when equipped with feeding and measuring devices.

Products Description

Machine Features

1.Easy to change bag size and bag type.

2. Easy to adjust Printer range.

3. Machine optoelectronic system can check bag, material filling and sealing situation to avoid failure.

4. Stable worktable with low noise and long life as the bottom drive system.

5. High bag opening effective and low machine failure rate.

6. Sample wiring arrangement with high quality electronic components

1.Easy to change bag size and bag type.

2. Easy to adjust Printer range.

3. Machine optoelectronic system can check bag, material filling and sealing situation to avoid failure.

4. Stable worktable with low noise and long life as the bottom drive system.

5. High bag opening effective and low machine failure rate.

6. Sample wiring arrangement with high quality electronic components

PRODUCT SPECIFICATIONS

|

Model

|

YFG-210

|

|

Pouch Size

|

90*110(min);195*260(max)

|

|

Filling Capacity

|

1000 ml

|

|

Packing Capacity

|

30--60 ppm

|

|

Power

|

4.5 kw

|

|

Air Consumption

|

3000NL/min

|

|

Dimension(L*W*H)

|

2950*980*1400mm

|

|

Weight

|

1000kg

|

|

Function

|

Flat Pouch, Doy Pack

|

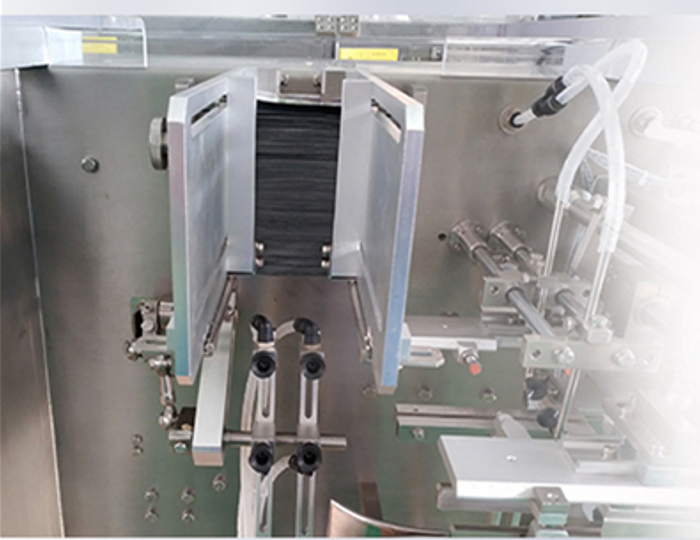

Machine Components

1.Duplex pouch feeding conveyor 2. Duplex Flip-out pouch-picking 3. Duplex Pouch Opening 4. Duplex Air Flushing 5. Filling I 6. Filling II 7. Pouch Stretching 8. Top Seal I 9. Top Seal II 10. Finished Product 11. Outlet

Our Advantages

High Compatibility

Independent blowing station

1. Effective improve the success rate of bag opening

2. Nitrogen can be blown to extend the shelf life

3. Bagless detection can be added to avoid material waste and reduce equipment pollution

2. Nitrogen can be blown to extend the shelf life

3. Bagless detection can be added to avoid material waste and reduce equipment pollution

Duplex Top Sealing

1. Increase the cold seal to ensure the firmness and aesthetics of the seal

Product packaging

Machine Package

Uvan provides professional packaging and logistic service for your option. With plenty of experience and carefully treatment , we

make sure the machinery delivery to your safe and sound.

* Machine packing inside is plastic films and outside is fumigation wooden case.

* Our wooden case is very strong; it can bear long time shipping on the sea.

* And machine with preservative film, it can stop the salt sea water enter into the machine and make the machine corrosion.

make sure the machinery delivery to your safe and sound.

* Machine packing inside is plastic films and outside is fumigation wooden case.

* Our wooden case is very strong; it can bear long time shipping on the sea.

* And machine with preservative film, it can stop the salt sea water enter into the machine and make the machine corrosion.

Why Choose Us

Quality Assurance

1. The warranty period is one year.

2. Ensure that the goods supplied meet the quality specifications and performance of the contract in all respects.

3. Ensure that the equipment has been properly installed and adjusted to meet the contractual requirement after the entire system is in operation.

4. Provide quantitative packaging scales with advanced design and excellent materials. The main components are selected from famous domestic and foreign manufacturers.

5. If the quality or specification of the goods is found to be inconsistent with the contract, or the goods are defective, the buyer has the right to exchange the parts and return he goods.

2. Ensure that the goods supplied meet the quality specifications and performance of the contract in all respects.

3. Ensure that the equipment has been properly installed and adjusted to meet the contractual requirement after the entire system is in operation.

4. Provide quantitative packaging scales with advanced design and excellent materials. The main components are selected from famous domestic and foreign manufacturers.

5. If the quality or specification of the goods is found to be inconsistent with the contract, or the goods are defective, the buyer has the right to exchange the parts and return he goods.

Machine

Installation

The installation can be provided.

It must be after shipment has arrived and factory must ready be equipped with all necessary requirement before booking installation with our company. Our engineers will come to the site for the complete and final installation.

During the installation session, a one-day training course will be provided to the customer for operation and maintenance procedure. The purchase at US$80/person/day plus all local transportation, air tickets (round trip), and hotel room & board is provided. Day charges include travel days.

FAQ

Q: Are you trading company or manufacturer?

A: We are manufacturer with trade team for international service.

Q: How long is your delivery time?

A: Normally 20 days after confirmed order. 15 days could be available in low season for some items (during May to July), and 45

days during new year and hot season (Jan to March).

Special cases need discuss.

Q: How do we test your machinery?

A: When the machine complete manufactured, we will send video for check, and you also can come to our factory to test and learn

how to operate it.

Q: What is your terms of payment?

A: Payment<=1000USD, 100% in advance.

Payment>=1000USD, 30% T/T in advance, balance before shipment.

A: We are manufacturer with trade team for international service.

Q: How long is your delivery time?

A: Normally 20 days after confirmed order. 15 days could be available in low season for some items (during May to July), and 45

days during new year and hot season (Jan to March).

Special cases need discuss.

Q: How do we test your machinery?

A: When the machine complete manufactured, we will send video for check, and you also can come to our factory to test and learn

how to operate it.

Q: What is your terms of payment?

A: Payment<=1000USD, 100% in advance.

Payment>=1000USD, 30% T/T in advance, balance before shipment.

Hot Searches