- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V~480V

-

Dimension(L*W*H):

-

2480x830x1200mm

-

Weight:

-

1400, 1400kgs

-

Power (kW):

-

27

-

Product Name:

-

1400kgs rubber conveyor belt splicing joint press machine

-

Heating Board Size:

-

830x2220mm

-

Belt Width:

-

2000mm

-

Fast Cooling Time:

-

5 minutes (from 145 degrees down to 70 degrees or less)

-

Max Working Pressure:

-

1.8MPa

-

Vulcanizing Temperature:

-

Adjustable

-

Heating Plates Material:

-

High quality aluminum alloys

-

Keyword:

-

Conveyor belt vulcanizer

-

Application:

-

Splicing and repairing conveyor belts

Quick Details

-

Place of Origin:

-

Shandong, China

-

Core Components:

-

platen

-

Brand Name:

-

EVERFINE

-

Voltage:

-

220V~480V

-

Dimension(L*W*H):

-

2480x830x1200mm

-

Weight:

-

1400, 1400kgs

-

Power (kW):

-

27

-

Product Name:

-

1400kgs rubber conveyor belt splicing joint press machine

-

Heating Board Size:

-

830x2220mm

-

Belt Width:

-

2000mm

-

Fast Cooling Time:

-

5 minutes (from 145 degrees down to 70 degrees or less)

-

Max Working Pressure:

-

1.8MPa

-

Vulcanizing Temperature:

-

Adjustable

-

Heating Plates Material:

-

High quality aluminum alloys

-

Keyword:

-

Conveyor belt vulcanizer

-

Application:

-

Splicing and repairing conveyor belts

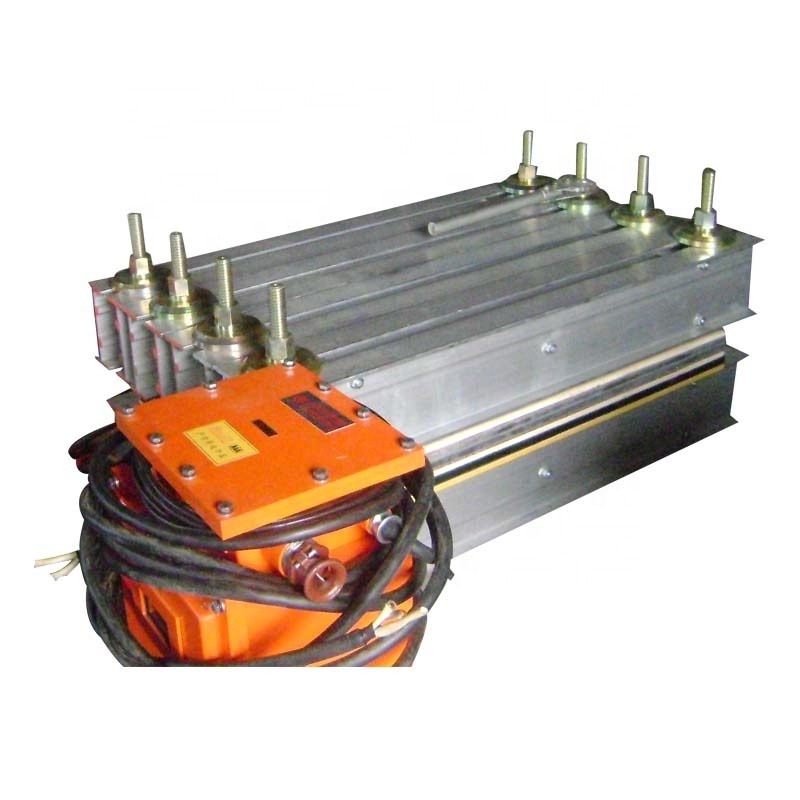

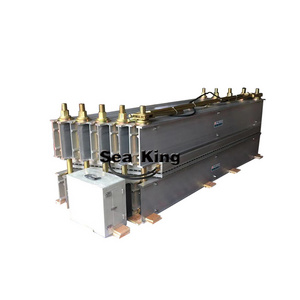

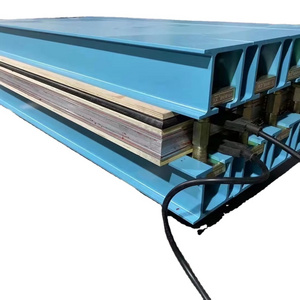

1400kgs rubber conveyor belt splicing joint press machine

E xplosion-proof type conveyor belt joint vulcanizing press is an electro thermal type vulcanizing device which is used for on-site bonding of conveyor belts, particularly suitable for use with methane or coal dust explosion hazard, poor operating environment corrosive occasions. With the advantages of advanced technology, compact structure and convenient usage, it’s used for the vulcanized bonding of the belts mixed with canvas, nylon, steel cord, etc., and it’s also suitable for the flame retarded, corrosion proof and other special belts. The application area of this kind of vulcanize is very wide, it can be used in metallurgy, mining, power plant, port and wharf, building material factory, chemical factory and so on.

Main features:

1. The electrical control system and the heating system are specially designed to meet the most stringent explosion protection standards.

2. The main parts of this vulcanizer is made of steel and aluminum alloy.

3. The electro thermal components are of multilayer structure, connected by three-phase electric circuit. It works stably and reliably on small current.

4. The heating plate shell is made of aluminum alloy, with low thermal inertia and directivity, can make better surface heating temperature uniformity.

5. During the working time of the heating plate, from warming to vulcanizing, the time and temperature are both controlled by the control box. It ensures low energy consumption, high efficiency, convenient operation, reliable work, and good vulcanization quality.

6. The type of the pressure device is hydraulic rubber water bag. Its structure is simple. It can make large and even pressure up to 3 Mpa during vulcanization.

|

Item |

Heating Board Size |

Belt Width |

Power |

Overall Dimension |

Weight |

|

CBSP-650 |

830x810mm |

650mm |

9.2kw |

1130x830x750mm |

450kgs |

|

CBSP-800 |

830x1020mm |

800mm |

11.2kw |

1220x830x750mm |

550kgs |

|

CBSP-1000 |

830x1220mm |

1000mm |

16.5kw |

1480x830x750mm |

650kgs |

|

CBSP-1200 |

830x1420mm |

1200mm |

18.6kw |

1680x830x800mm |

800kgs |

|

CBSP-1400 |

830x1620mm |

1400mm |

20.8kw |

1880x830x900mm |

950kgs |

|

CBSP-1600 |

830x1820mm |

1600mm |

22.2kw |

2080x830x900mm |

1150kgs |

|

CBSP-1800 |

830x2020mm |

1800mm |

24.8kw |

2280x830x900mm |

1250kgs |

|

CBSP-2000 |

830x2220mm |

2000mm |

27kw |

2480x830x1200mm |

1400kgs |

|

CBSP-2200 |

830x2420mm |

2200mm |

28.8kw |

2680x830x1200mm |

1500kgs |

|

CBSP-2400 |

830x2620mm |

2400mm |

30.2kw |

2880x830x1200mm |

1700kgs |