- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Intertech 02056

-

Products:

-

Hydraulic press mold factory

-

Size:

-

According to your drawing

-

Structure:

-

According to your drawing

-

Color:

-

Can be discussed

-

Mould Base:

-

HASCO standard, European standard, World standard

-

Surface Finish:

-

Texture (MT standard), high gloss polishing

-

Finish:

-

Mirror finish etc.

-

Cavity:

-

Single Cavity or Muti Cavity, based on customer's requirement

-

Mold material:

-

German and Japan import steel

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Taiwan, China

-

Brand Name:

-

Intertech

-

Model Number:

-

Intertech 02056

-

Products:

-

Hydraulic press mold factory

-

Size:

-

According to your drawing

-

Structure:

-

According to your drawing

-

Color:

-

Can be discussed

-

Mould Base:

-

HASCO standard, European standard, World standard

-

Surface Finish:

-

Texture (MT standard), high gloss polishing

-

Finish:

-

Mirror finish etc.

-

Cavity:

-

Single Cavity or Muti Cavity, based on customer's requirement

-

Mold material:

-

German and Japan import steel

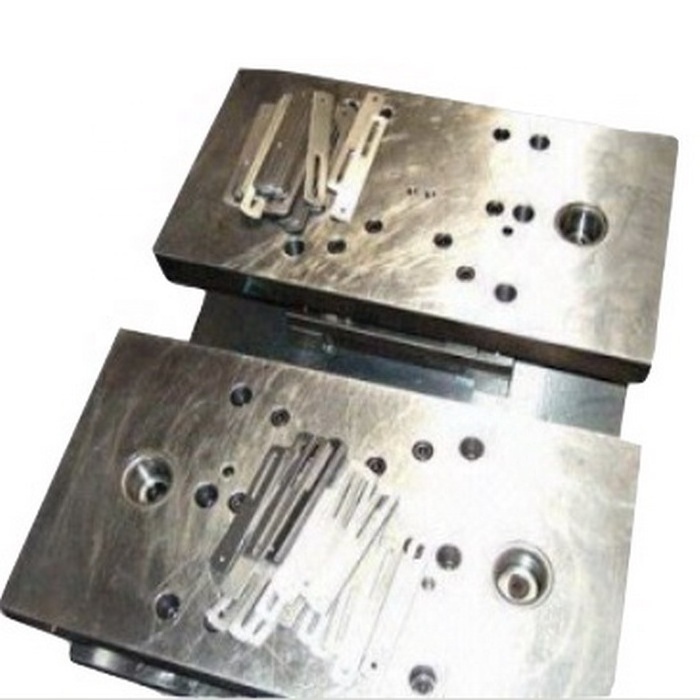

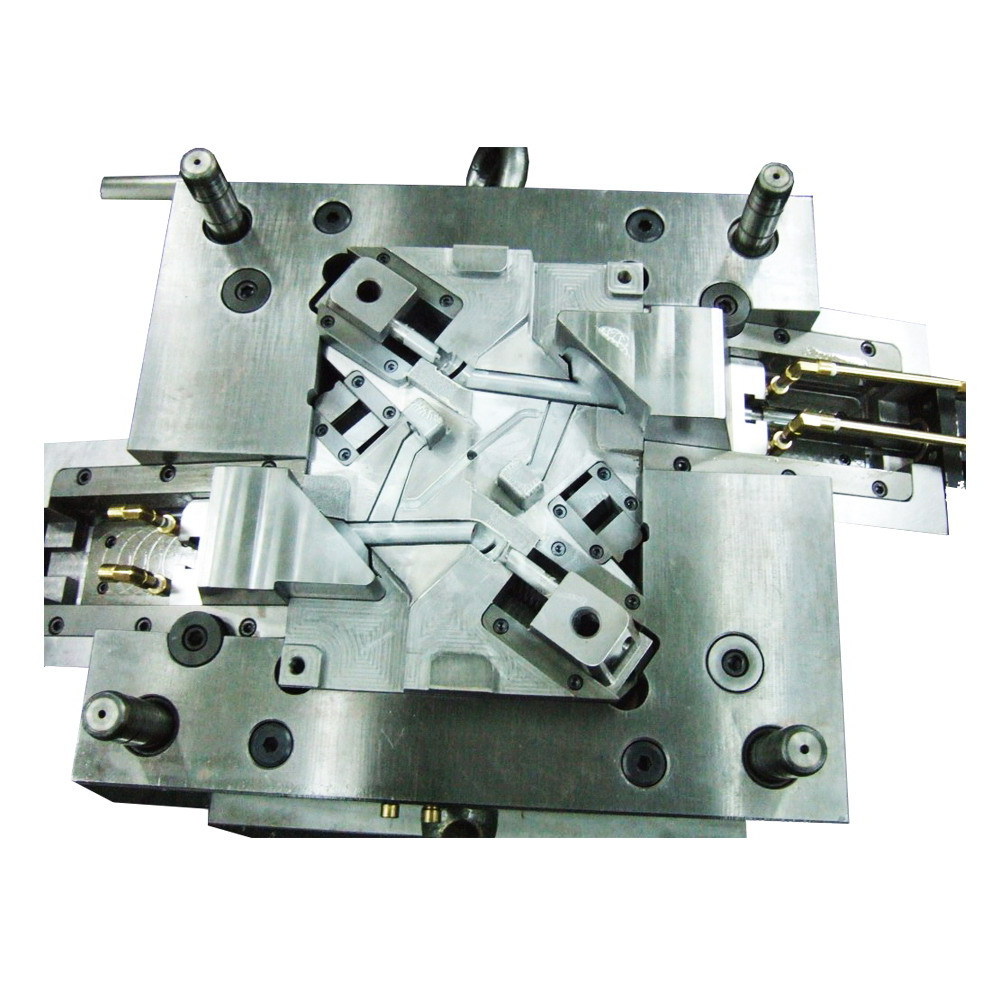

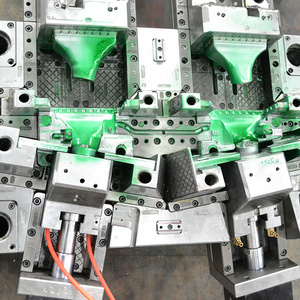

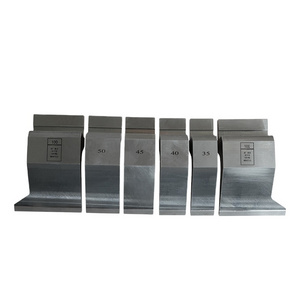

Hydraulic press mold factory

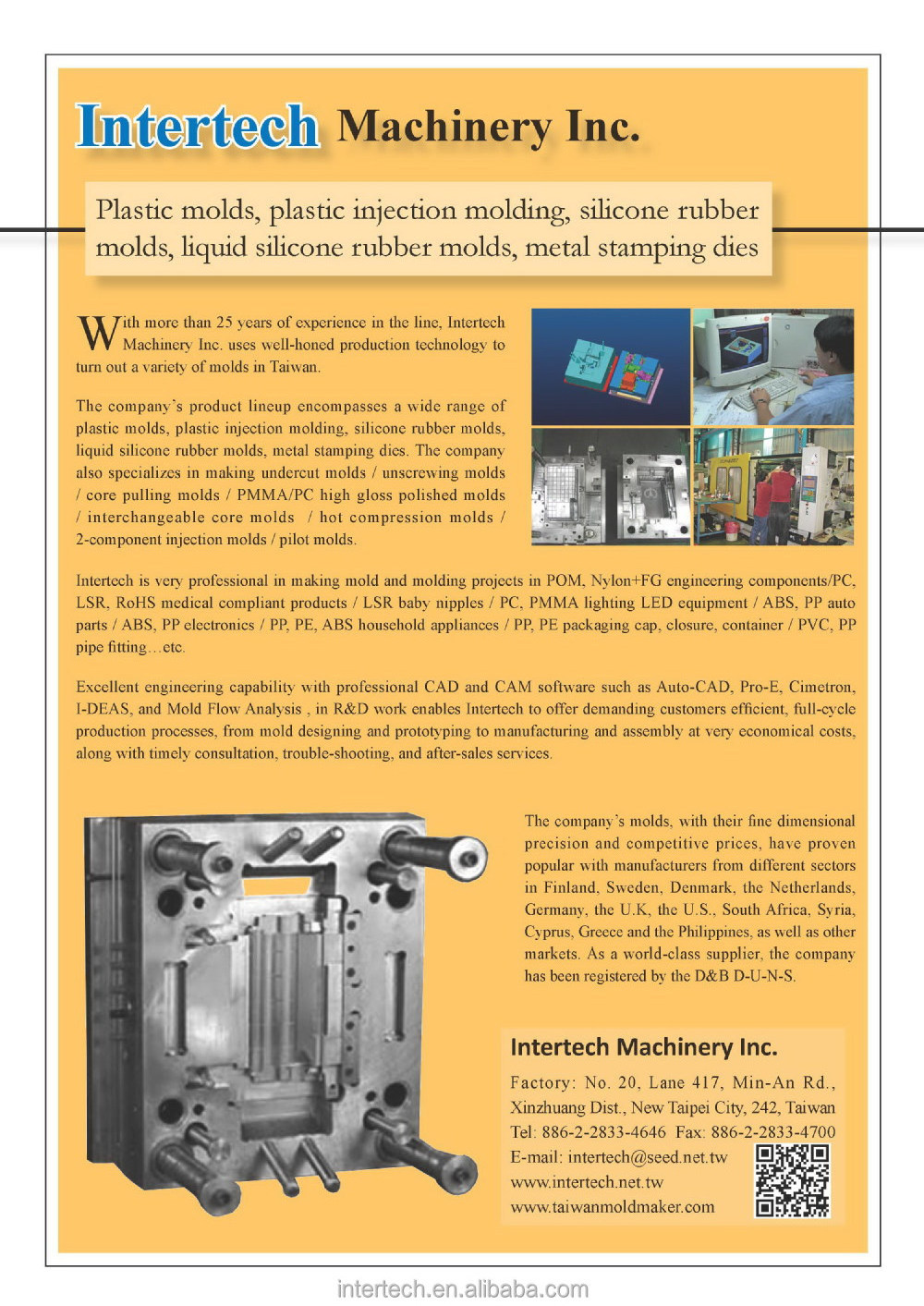

Our Professionals:

1. Making interchangeable cores mold : a most effective and cost-saving manufacturing process. Suitable for customers looking for “more variety but less quantity” solution. With only one mold, it can efficiently generate different kinds of products,

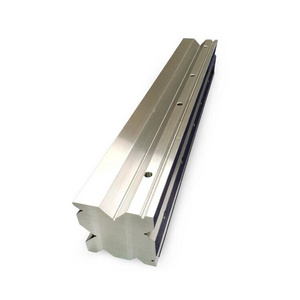

2. Making high transparent PC, Acrylic, PMMA, PET.. parts mold with high gloss polishing and Mold-Tech texture on parts surface, applied mostly in lighting parts, outdoor LED parts projects.

3. Making gas assisted injection molds and products projects …mostly applied in projects like the thick handles, monitors, the frame of TV cabinet etc, which prevents the shrinkage mark, improves the strength of the parts and saves material costs.

4 Medical silicone and rubber molds/products making : We manage both “solid” and “liquid” silicone rubber material meeting the standard of RoHS, and REACH, and can be applied like skincare parts, medical earplugs, nipple pacifier, check valve, diving mask.

|

Plastic materials: |

PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc. |

|

Other materials: |

Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

|

Quality: |

ROSH and SGS standard |

|

Feature: |

Non marking and Non flash |

|

Size: |

According to your drawing |

|

Color, Quantity, Unit price, Tooling cost, Tooling size: |

To be discussed |

|

Mold structure: |

Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

|

Mould Base: |

HASCO standard, European standard, World standard |

|

Mould Base Material: |

LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

|

Surface Finish: |

Texture (MT standard), high gloss polishing |

|

Finish: |

Mirror finish etc. |

|

Cavity / Core steel: |

P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

|

Cavity: |

Single cavity, Muti Cavity, based on customer’s requirement. |

|

Hot / Cold Runner: |

HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc. |

|

Mould Life: |

1,000 to 1,000,000 shots (according to your working environment) |

|

Design & Program Softwares: |

CAD, CAM, CAE, Pro-E, Solid works…etc. |

|

Equipments: |

High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

|

Package: |

Standard exported wooden box packed, fumigation process (upon required) |

|

Mold building lead time: |

T1, 40~50 days, parts measurement report (upon required). |

|

Annual production: |

250 sets of mold |