- Product Details

- {{item.text}}

Quick Details

-

Length:

-

2000-6000mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

xinzhou

-

Model Number:

-

DMW

-

Side Rail Height:

-

50-200mm

-

Max. Working Load:

-

customed

-

Certification:

-

CE ISO9001

-

Product Name:

-

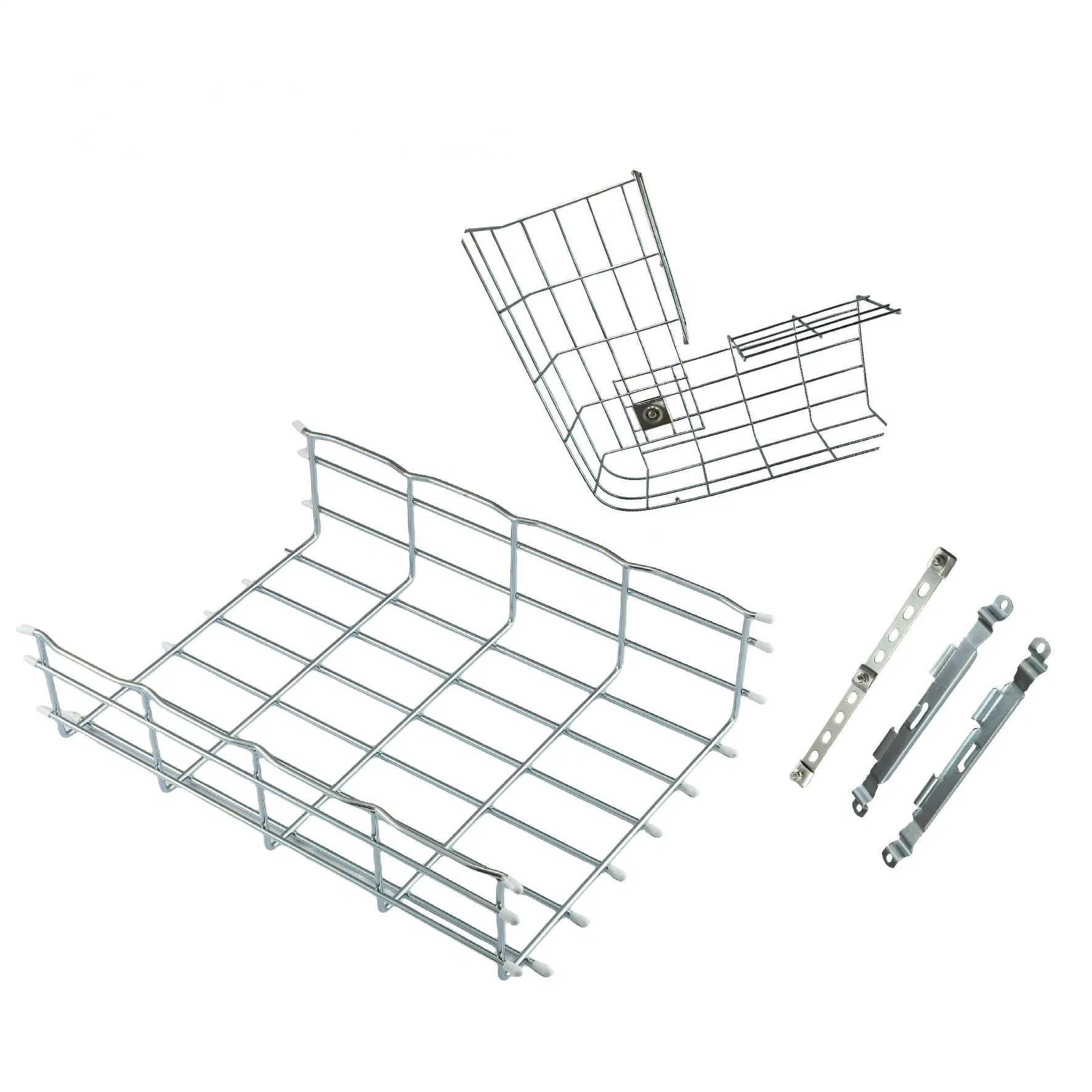

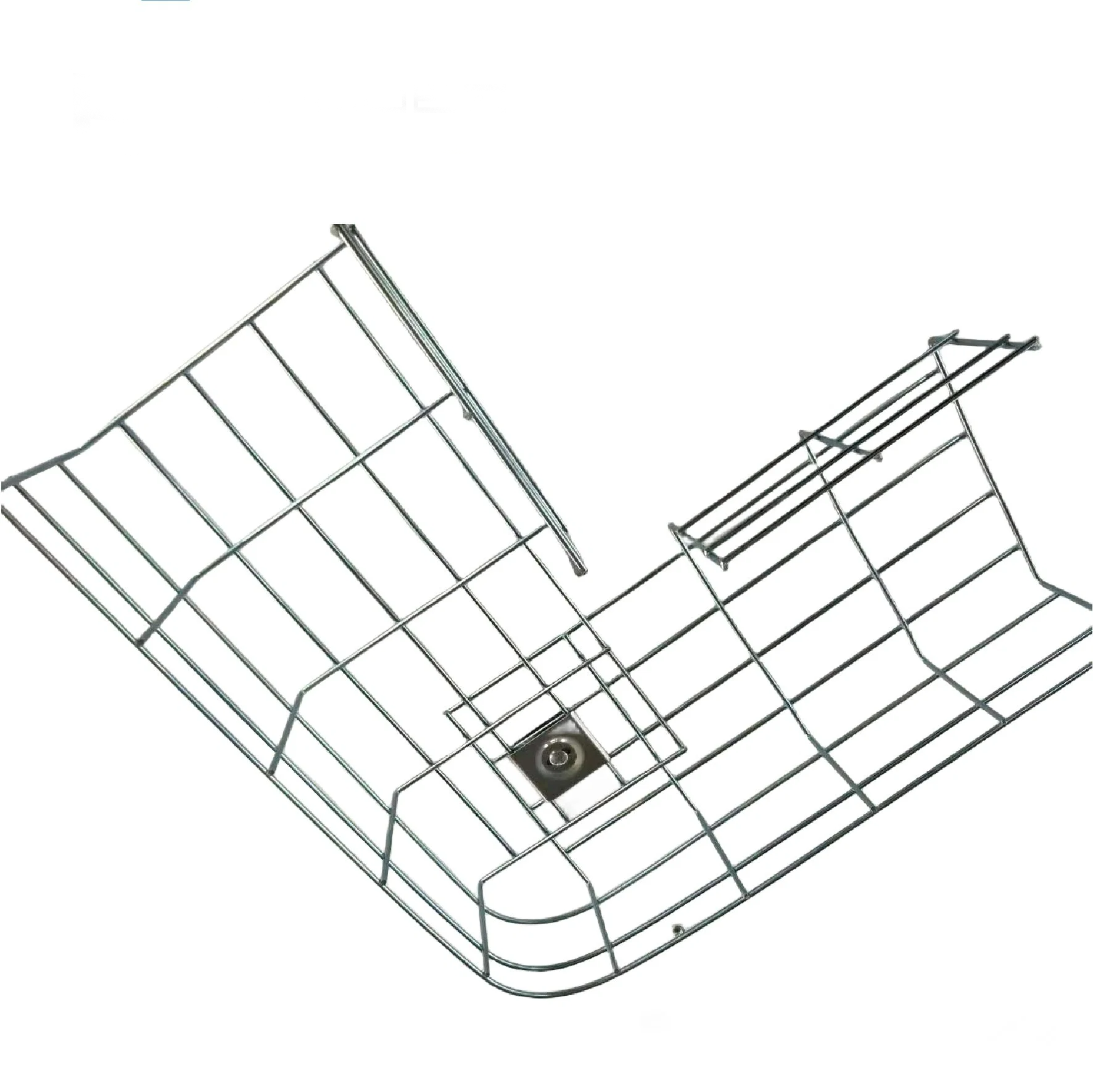

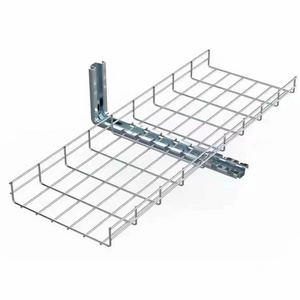

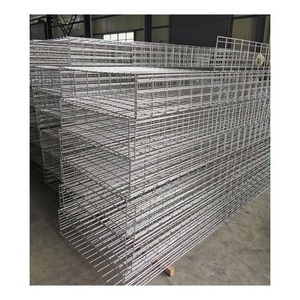

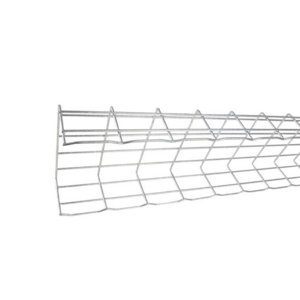

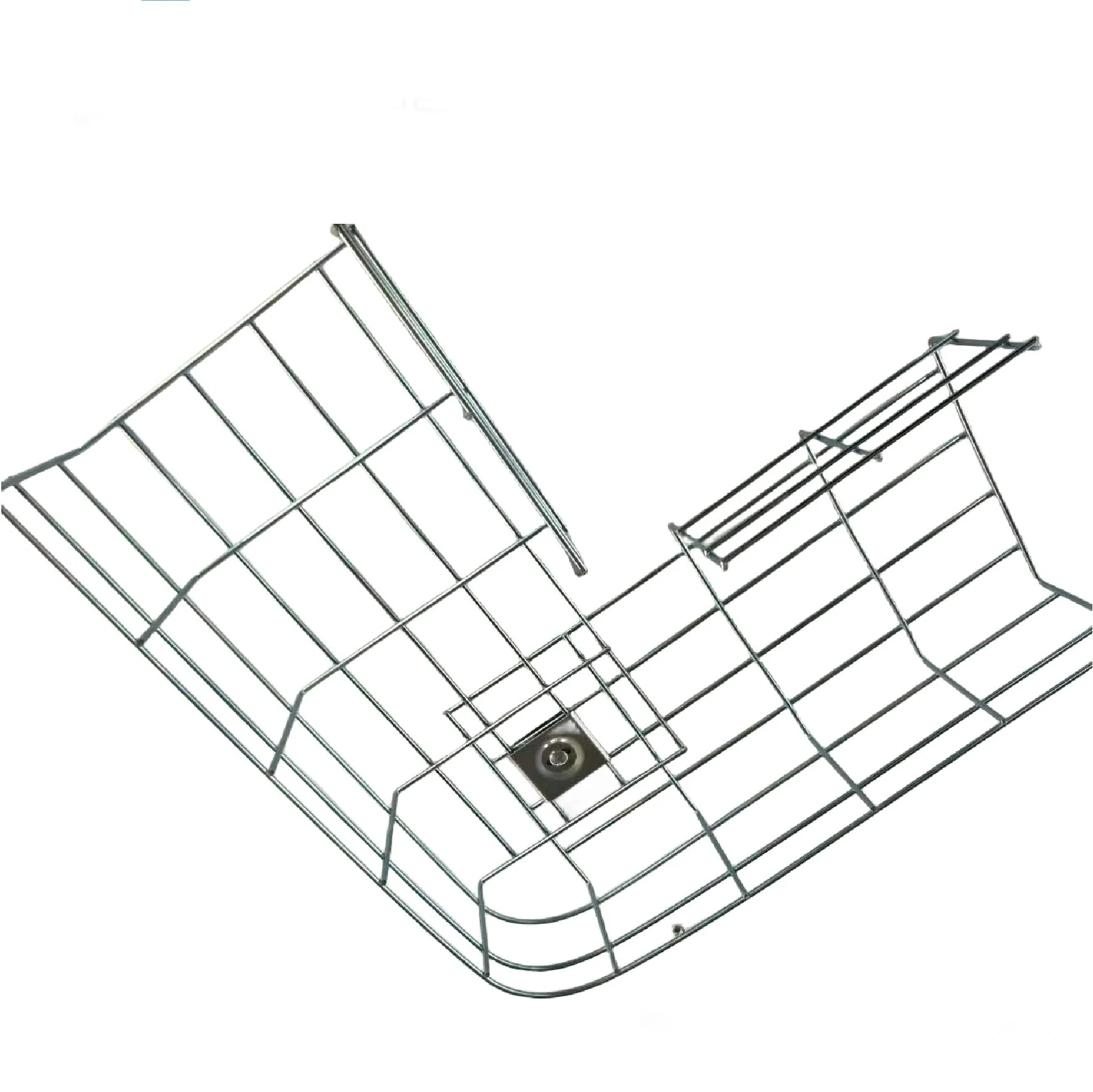

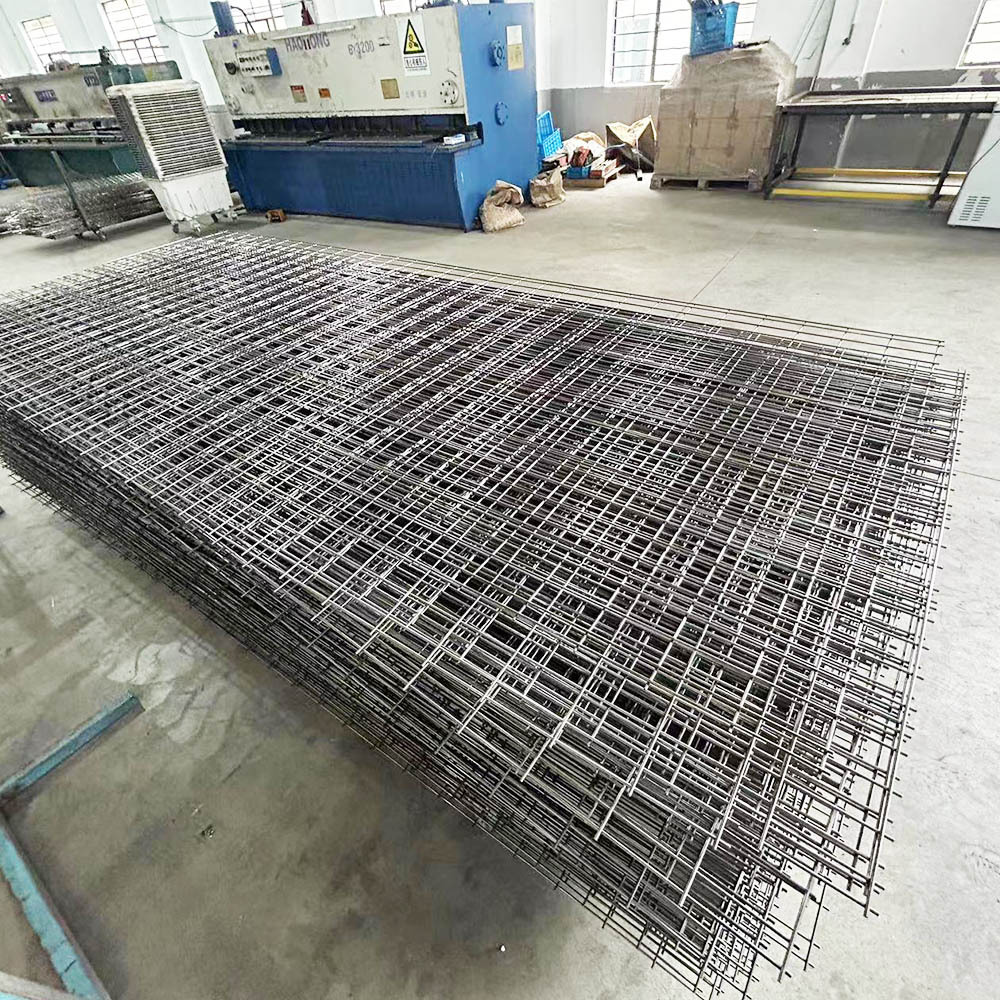

Wire Mesh Cable Tray

-

Application:

-

Plarform Building Ladder Cable Tray

-

Customized:

-

Customers Specifications

-

Surface Treatment:

-

Powder Coated

-

All Finishes:

-

Pre-Gal, Electro-Gal, HDG, Powder Coated

-

Cable Tray Type:

-

Solid, Perforated, Ladder Type, Wire Mesh, FRP

-

Supply Ability:

-

400 Tons Per Month

-

Diamater:

-

3.8-6.0mm

Quick Details

-

Type:

-

Wire Mesh

-

Material:

-

Steel

-

Width:

-

50-1200mm

-

Length:

-

2000-6000mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

xinzhou

-

Model Number:

-

DMW

-

Side Rail Height:

-

50-200mm

-

Max. Working Load:

-

customed

-

Certification:

-

CE ISO9001

-

Product Name:

-

Wire Mesh Cable Tray

-

Application:

-

Plarform Building Ladder Cable Tray

-

Customized:

-

Customers Specifications

-

Surface Treatment:

-

Powder Coated

-

All Finishes:

-

Pre-Gal, Electro-Gal, HDG, Powder Coated

-

Cable Tray Type:

-

Solid, Perforated, Ladder Type, Wire Mesh, FRP

-

Supply Ability:

-

400 Tons Per Month

-

Diamater:

-

3.8-6.0mm

Product Description

|

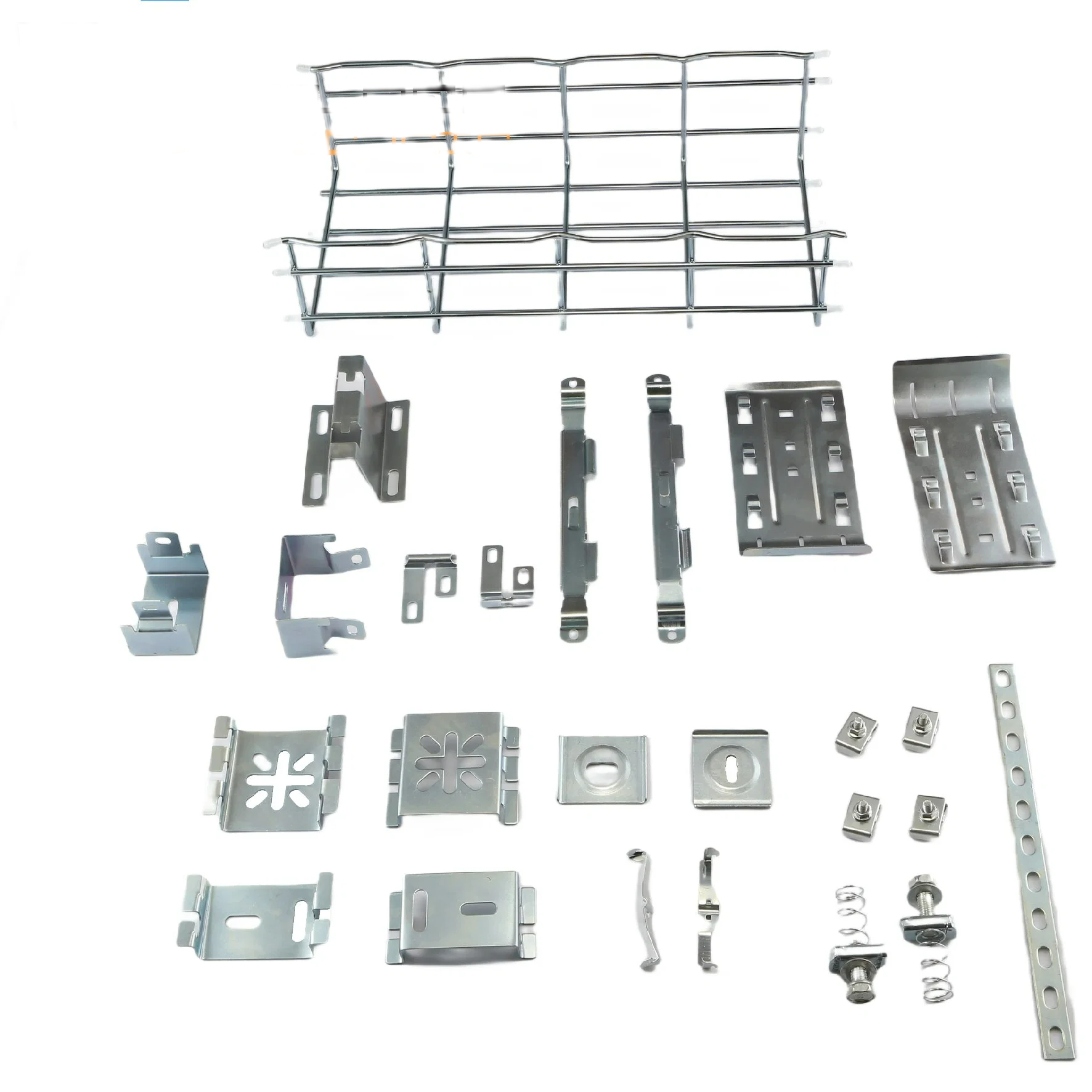

Product Parameter

|

|

|

|

Product Type

|

Cable trunking, ladder type cable tray, perforated cable tray, wire mesh cable tray

|

|

|

Material

|

GI sheet, SPHC, ZAM, ZN/AL, Aluminum, Stainless Steel 304/316, FRP and other metal materials

|

|

|

Surface Treatment

|

Pre-Gal, Electro-Gal, HDG, Powder Coated, Electrolytic Polishing - for Stainless Steel use

|

|

|

Packing method

|

Pallet or according to requirments

|

|

|

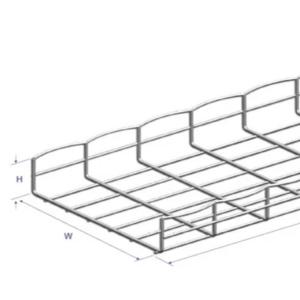

Width

|

20-1000mm

|

|

|

Height

|

25mm, 50mm, 75mm, 100mm, 150mm, 200mm or as you required.

|

|

|

Thickness

|

0.5-3.0mm (Diameter:4mm-6mm for wire mesh cable tray)

|

|

|

Length

|

2m,2.4m,2.44m,2.5m,3m,6m

|

|

|

Accept

|

OEM/ODM Service, Accept trial orders

|

|

|

Certification

|

CE; TÜV; CCC; ISO

|

|

|

Samples

|

Free custom samples

|

|

|

Used

|

Strut Channel System,Construction Industry,Machinery frame and rail system and so on

|

|

Wire Mesh Cable Tray Welding Machine

●Using intermediate frequency inverter DC square wave output, the welding heat is concentrated and the solder joints are symmetrical. It is especially suitable for the welding of non-ferrous metal materials and some difficult-to-weld materials. The welding process is stable, the welding quality is significantly improved, the production efficiency is rapidly improved, and the scope of use of the equipment is also expanded.

●

The welding transformer used in the intermediate frequency inverter power supply is small in size and has a large output energy, which greatly reduces the weight of the iron core material. In addition, the rectifier diode in the secondary circuit of the transformer converts the electric energy into a DC power supply for welding, improving The value of the secondary loop inductance prevents large energy losses, thereby reducing production costs.

●Using microcomputer control, it can store multiple sets of welding specifications, and the user can edit the cylinder action sequence, the number of cylinder actions and the corresponding welding specifications to realize the welding of different products.

●The integrated ultra-wide gantry frame is welded by high-quality steel. The lower beam is annealed after welding with 45# reinforcing ribs. The elastic deformation is small and there is no deformation. Ensure the deformation of the whole fuselage when the welding cylinder is pressed down at the same time, and also prevent product misalignment caused by the instability of the fuselage during welding.

Manual/Automatic Welding

According to each customer demand, provide manual welding type and automatic welding type.

Intermediate frequency inverter DC square wave output

Rapidly improved the

production efficiency, and the scope of use of the equipment is also expanded.

Single/Multiple Welding Head

Design multiple welding heads according to different sizes of mesh, and the welding efficiency is higher.

Custom Welding Electrode

According to the characteristics of the mesh, the appropriate welding electrode is processed.

Product Parameter

Company Introduction

PRICE

We provide good quality machine with competitive price.

CUSTOMIZE

We will customize the machine according to your requirement.

QUALITY

We have strict QC procedure to ensure the machine quality before shipment.

AFTER-SALES

Free online guidance and overseas commissioning service available.

Ningbo Xinzhou Welding Equipment Co., Ltd. was founded in

1998

, is a company mainly engaged in researching, designing, manufacturing and selling automation welding equipment, which is also a national high-new tech enterprises in China. Its products are widely used in home appliances,hardware, auto parts production, petrochemical, liquid packaging, nuclear power station,hydropower station, steel structure platform, expressway, high-speed railway, rail transit and other large-scale infrastructure construction and precast constructions. With excellent quality and perfect service, the company has been widely recognized and unanimously praised by customers, products sell well in more than 80 countries and regions, and cooperate with a number of well-known enterprises to establish a long-term strategic partnership.

Intelligent Production Plant

covers an area of 130 acres and more than 35,000 square meters, with large-scale modern production workshop, finished product testing workshop and Technology Research and Development Center.

Global Sales Network

Our machines have been exported to more than 80 countries in the world. Local service team available in some specific area and increasing every year.

Technical Service Team

Professional engineering team with more than 20 years experience in welding industry to serve you. 24-hour fast online service available.

Certification

We have obtained ISO9001 certificate and CE certificate. We got more than 70 patents qualified by Chinese National Patent Office.

Certificate

Certificate of compiance

qualty management syatem

factory production control

Customer visit

Exhibition

Since its establishment

25 years ago

,

xinzhou has traveled to all corners of the world, participated in more than

100

exhibitions and served more than

9,000

customers

Packing&Shipping

Acceptable Delivery Terms

EXW, FOB, C&F, CIF, DDU, DDP

Quality Control

Strictly control all aspects of incoming materials,processing, assembly, commissioning, testing, packaging and shipping to ensure the performance and quality of welding products.

Professional Package

1. Whole film packaging machine; 2. Anti-collision package edge; 3. Wooden box and pallets with iron binding belt.

FAQ

Q1: What is the price of your machine?

Answer: our machines are customized for your requirements. If you want to get the appropriate price, please provide us thefollowing information.

* The material and thickness of your product

* The minimum and maximum size of your product

* The welding position of your products

* The automation level that you want to achieve

* It would be better if you can provide us the detailed product drawings so our engineer can come out with the suitable technical proposal and price for you.

Q2: What is the warranty period of your machine?

Answer: our standard warranty period is one year after shipment. If you want to extend the warranty period, there will be extra cost.

Q3: What if my machine damaged doing the warranty period?

Answer: firstly, our engineer will help you to diagnose the problem via online guidance. if any parts damaged during the warranty period, we will send the parts to you for replacement free of charge. If you can not fix he problem by replacement of the new parts, we will send engineer to your factory to help fixing the machine.

Q4: What is the delivery time of your machine?

Answer: it depends on the complexity of your machine. Most of our standard machine we got in stock, then we can shape the machine with the seven days after receiving your payment. If you need the Customized machine, normally it would take about 30-90 days to complete the machine.

Q5: Can we send the sample to you for welding test?

Answer: yes. You can send us the samples for welding test and we will send you the pictures and videos after the testing. If you need, we can also send the samples back to your country so you can check the welding quality by yourself before ordering the machine.

Q6: Can you provide us the machine drawings and technical proposal?

Answer: yes. After receiving your detailed requirement and product drawings, our engineer will come out with the suitable

Technical proposal with the basic machine concept drawings to you. Be size after you placing the order we will send you the more detailed design drawings of the machine to you for confirmation. Only after you confirming the drawings then we will start the manufacturing process.

Q7: What’s your payment terms?

Answer: we can accept the following payment terms: T/T, L/C, Western Union, Alibaba trade assurance. (we prefer you to choose the Alibaba trade assurance order. If you are not satisfied with the machine that you order, or we delay the shipping time, then you can apply the complaint on alibaba.com. )

Q8: How can we install the machine?

Answer: for some simple machines we will provide you the english operation manual, the operation video and also we will provide you the online guidance and training to your engineer so you can set up the machine easily. For some complicated machines, we will send engineer to your country to help installation and training. But there will be extra cost for Engineer, including the salary, visa cost, round-trip ticket cost, and accommodation fee will be covered by the buyer.

Answer: our machines are customized for your requirements. If you want to get the appropriate price, please provide us thefollowing information.

* The material and thickness of your product

* The minimum and maximum size of your product

* The welding position of your products

* The automation level that you want to achieve

* It would be better if you can provide us the detailed product drawings so our engineer can come out with the suitable technical proposal and price for you.

Q2: What is the warranty period of your machine?

Answer: our standard warranty period is one year after shipment. If you want to extend the warranty period, there will be extra cost.

Q3: What if my machine damaged doing the warranty period?

Answer: firstly, our engineer will help you to diagnose the problem via online guidance. if any parts damaged during the warranty period, we will send the parts to you for replacement free of charge. If you can not fix he problem by replacement of the new parts, we will send engineer to your factory to help fixing the machine.

Q4: What is the delivery time of your machine?

Answer: it depends on the complexity of your machine. Most of our standard machine we got in stock, then we can shape the machine with the seven days after receiving your payment. If you need the Customized machine, normally it would take about 30-90 days to complete the machine.

Q5: Can we send the sample to you for welding test?

Answer: yes. You can send us the samples for welding test and we will send you the pictures and videos after the testing. If you need, we can also send the samples back to your country so you can check the welding quality by yourself before ordering the machine.

Q6: Can you provide us the machine drawings and technical proposal?

Answer: yes. After receiving your detailed requirement and product drawings, our engineer will come out with the suitable

Technical proposal with the basic machine concept drawings to you. Be size after you placing the order we will send you the more detailed design drawings of the machine to you for confirmation. Only after you confirming the drawings then we will start the manufacturing process.

Q7: What’s your payment terms?

Answer: we can accept the following payment terms: T/T, L/C, Western Union, Alibaba trade assurance. (we prefer you to choose the Alibaba trade assurance order. If you are not satisfied with the machine that you order, or we delay the shipping time, then you can apply the complaint on alibaba.com. )

Q8: How can we install the machine?

Answer: for some simple machines we will provide you the english operation manual, the operation video and also we will provide you the online guidance and training to your engineer so you can set up the machine easily. For some complicated machines, we will send engineer to your country to help installation and training. But there will be extra cost for Engineer, including the salary, visa cost, round-trip ticket cost, and accommodation fee will be covered by the buyer.

Hot Searches