1. A

dopts double-layer shell structure and air cooling system to make the shell surface temperature lower than 60 ℃.

2.

The chamber adopts high purity alumina fiber to reduce energy loss.

3.

Supports protection for over-temperature and for open circuit of thermocouple.

4.

The tube is made of high temperature alloy steel GH3128.

5.

The panel is

provided with a pressure sensor and a digital display, showing inlet pressure.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Anhui, China

-

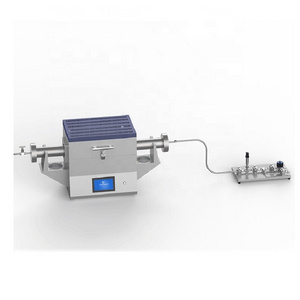

Product name:

-

Labraotory Tube Furnace

-

Application:

-

Laboratory Heating Test Equipment

-

Max temperature:

-

1200

-

Dimension:

-

1400*600*1200 mm

-

Keywords:

-

1200c Muffle Furnace

-

Usage:

-

High Temperature Sintering

-

Type:

-

Horizontal Tube Furnace

-

Material:

-

Quartz Glass

-

Power Supply:

-

220V/50Hz-60Hz

-

MOQ:

-

1 Set

Quick Details

-

Warranty:

-

1 year

-

Brand Name:

-

CHEMN

-

Model Number:

-

TFP-1200-50-440

-

Place of Origin:

-

Anhui, China

-

Product name:

-

Labraotory Tube Furnace

-

Application:

-

Laboratory Heating Test Equipment

-

Max temperature:

-

1200

-

Dimension:

-

1400*600*1200 mm

-

Keywords:

-

1200c Muffle Furnace

-

Usage:

-

High Temperature Sintering

-

Type:

-

Horizontal Tube Furnace

-

Material:

-

Quartz Glass

-

Power Supply:

-

220V/50Hz-60Hz

-

MOQ:

-

1 Set

Product Paramenters

|

TFP High-Pressure Tube Furnace Technical Parameters

|

|

|

|

Model

|

TFP-1200-50-I-440

|

|

|

Body structure

|

The body is designed as open type

The furnace adopts double-layer shell structure and air cooling system to make the shell surface temperature lower than 60 ℃

The chamber adopts high purity alumina fiber to reduce energy loss

The flanges are equipped with cooling fans to keep their temperature lower than 80 ℃

|

|

|

Temperature control system

|

PID is adopted to control heating and cooling and supports protection for over-temperature and for open circuit of thermocouple ·

PC temperature control software can be selected to import temperature control program and temperature curve to the computer. |

|

|

Comparison between operating temperature and pressure

|

· Maximum pressure in the tube: ≤5 MPa, ≤6 MPa, ≤7 MPa, ≤9 MPa · Heating temperature: ≤750 ℃, ≤500 ℃, ≤400 ℃, ≤200 ℃

|

|

|

Tube parameters

|

The tube is made of high temperature alloy steel GH3128

Size: φ50*φ42*1,000 mm

|

|

|

Operating gas

|

Inert gas and nitrogen

Flammable and explosive gas should not be passed (please consult Kemi technician if needed)

|

|

|

Inlet flow control

|

The panel is provided with a pressure sensor and a digital display, showing inlet pressure

A high pressure proton flux controller with 10 MPa operating pressure and 500SCCM flux control is installed at the air let of the tube

|

|

|

Product collection device

|

Condenser, which shall be used in conjunction with a low temperature thermostatic bath (-20-98 ℃)

Gas-liquid separator with sampling valve at the bottom

|

|

|

Exhaust gas collection

|

Gas bag for real-time gas collection during the reaction

Flow monitoring system at exhaust gas end

|

|

|

Outline dimension

|

1400*600*1200 mm

|

|

Product Features

Features

|

Model List of TFP Series High-Pressure Tube Furnaces

|

|

|

|

|||

|

Type

|

Parameter

|

Model code

|

Remarks

|

|||

|

Operating temperature (℃)

|

600

|

600

|

|

|||

|

|

800

|

800

|

|

|||

|

|

1000

|

1000

|

|

|||

|

|

1100

|

1100

|

|

|||

|

Pressure (MPa)

|

3

|

3

|

Determine the product model together with the temperature parameter

|

|||

|

|

5

|

5

|

|

|||

|

|

10

|

10

|

|

|||

|

|

Customizable

|

--

|

|

|||

|

Tube parameter (mm)

|

φ30

|

30

|

|

|||

|

|

φ50

|

50

|

|

|||

|

|

φ80

|

80

|

|

|||

|

|

Customizable

|

--

|

|

|||

|

Material

|

310S

|

310S

|

Determine the product model together with the temperature parameter Other materials are customizable

|

|||

|

|

GH3128

|

3128

|

|

|||

|

|

GH202

|

202

|

|

|||

|

Number of heating zones

|

I

|

I

|

|

|||

|

|

II

|

II

|

|

|||

|

|

III

|

III

|

|

|||

|

|

Customizable

|

--

|

|

|||

|

Heating zone length (mm)

|

200

|

200

|

|

|||

|

|

220

|

220

|

|

|||

|

|

440

|

440

|

|

|||

|

|

Other

|

--

|

|

|||

Certifications

Hot Searches