- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Sino-Tech

-

Weight:

-

1270 KG

-

Dimension(L*W*H):

-

3400*1850*1650mm

-

Usage:

-

Liner cutting and inserting into caps

-

Compressed air:

-

0.5m3

-

Production capacity:

-

6000-8000pcs/hr

-

Automatic grade:

-

Automatic

-

material:

-

stainless steel

-

Packaging type:

-

Case

-

Key Word:

-

cap lining machine

-

Belong:

-

Other Packaging Machines

-

Model Number:

-

FRTB-SD2-B

-

Function:

-

cap liner/wad cutting inserting machine

Quick Details

-

Voltage:

-

220V

-

Power:

-

2.2kw

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sino-Tech

-

Weight:

-

1270 KG

-

Dimension(L*W*H):

-

3400*1850*1650mm

-

Usage:

-

Liner cutting and inserting into caps

-

Compressed air:

-

0.5m3

-

Production capacity:

-

6000-8000pcs/hr

-

Automatic grade:

-

Automatic

-

material:

-

stainless steel

-

Packaging type:

-

Case

-

Key Word:

-

cap lining machine

-

Belong:

-

Other Packaging Machines

-

Model Number:

-

FRTB-SD2-B

-

Function:

-

cap liner/wad cutting inserting machine

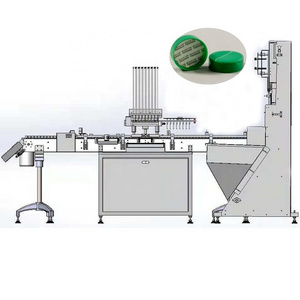

High quality cap lining machine for sale

Application:

Cap lining machine is an ideal liner inserting machine which is widely applied in cap factories, liner factories, food products factories, daily chemical factories, packing factories, etc..

Operation principle:

hoist cap feeder sorting and feeding caps into the conveyor with upwards direction,then cut the reeled liner materials into specified size and simultaneously insert the precut liner into the cap; finally, the liner pressing unit press the liner to the bottom of the cap and shapping.

Process:

Feeding the caps — cutting the liner —inserting Liners into caps— counting the caps — Outlet.

Structure:

Automatic cap hoist sorting and feeder: it can sorting the disorder caps to be orderly through rotation and make all caps with the mouths upward.

Cap conveying unit: accurately and orderly convey the arranged caps to the liner inserting unit.

Liner inserting unit: insert the liner into the cap.

Unit for sifting caps with reverse-sided liners or without liner: it can automatically sift caps with reverse-sided liners or without liner, thus to guarantee that all caps are qualified. (Optional)

Machine capacity: 100-120 pcs/Min.

Power: 2.2 KW, 220V.single Phase or 380 V,3 phases,50/60 HZ.