- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Gansu, China

-

Width:

-

customizable

-

Ti (Min):

-

customizable

-

Brand Name:

-

SUPERALLOY

-

Model Number:

-

TA7/GR6/BT5-1

-

Product Name:

-

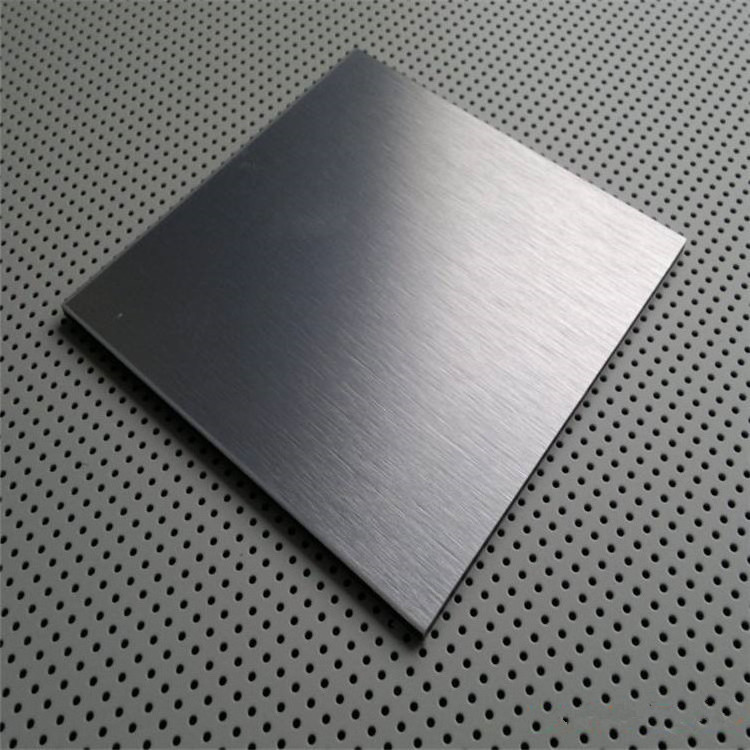

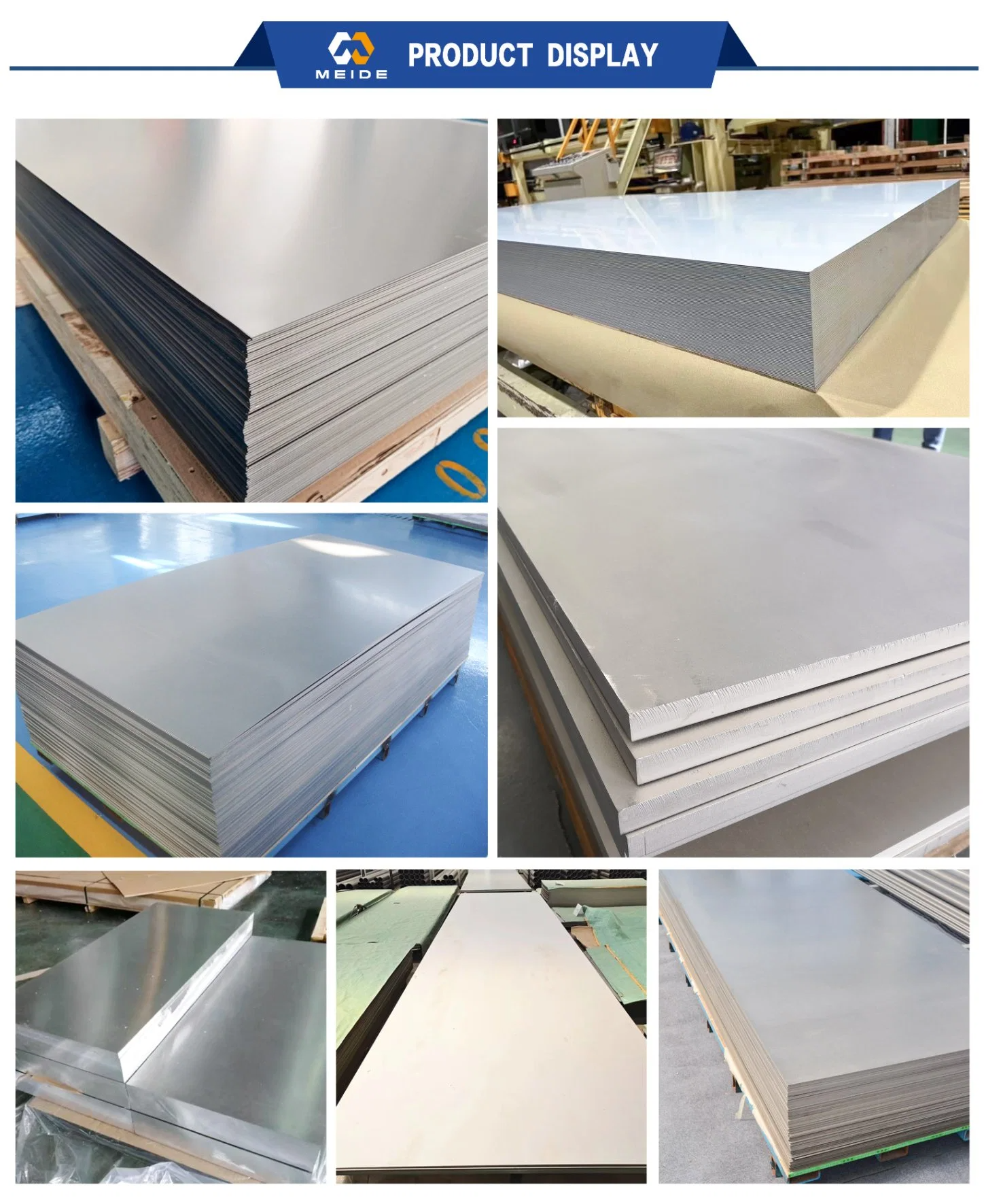

Titanium Alloy Plate

-

Shape:

-

Custom Made

-

Keyword:

-

Titanium Plate GR1

-

Advantage:

-

High Strength

-

Type:

-

Sheet Plate Foil Strip

-

Standard:

-

ASTM B 265

-

Surface:

-

Polished

-

Feature:

-

Low Density High Strength

-

MOQ:

-

1 Ton

-

CERTIFICATION:

-

ISO9001

Quick Details

-

Application:

-

Ship pressure hull,heatexchanger,etc.

-

Length:

-

customizable

-

Technique:

-

Hot Rolled

-

Place of Origin:

-

Gansu, China

-

Width:

-

customizable

-

Ti (Min):

-

customizable

-

Brand Name:

-

SUPERALLOY

-

Model Number:

-

TA7/GR6/BT5-1

-

Product Name:

-

Titanium Alloy Plate

-

Shape:

-

Custom Made

-

Keyword:

-

Titanium Plate GR1

-

Advantage:

-

High Strength

-

Type:

-

Sheet Plate Foil Strip

-

Standard:

-

ASTM B 265

-

Surface:

-

Polished

-

Feature:

-

Low Density High Strength

-

MOQ:

-

1 Ton

-

CERTIFICATION:

-

ISO9001

|

Titanium alloy product types

|

|

|

|

|

|

|||||

|

Main titanium alloy grades

|

|

|

Performance parameter

|

|

Product specifications

|

|||||

|

Chinese

standard |

American

standard |

Russian

standards |

Rm

|

RPo.2

|

Plate

sheets: (0.6-6.0mm)×(600-1200mm)×L

plate: (6.0-200mm)×(600-2200mm)×L

Bar

(φ35~450mm)×L(870mm~6000mm)

wire

(φ1.2~8.0mm)×L

Forging

Dises general: D≤2000mm,H≤400mm

Shaft: (φ80~600mm)×L≤6000mm

Ring

piece:D≤5030mm,70mm≤8≤350mm,H≤1000mm

Barrel

type:D≤2000mm,24mm≤δ≤200mm,L≤2700mm

|

|||||

|

TA1

|

GR1

|

BT1-00

|

615

|

241

|

|

|||||

|

TA7

|

GR6

|

BT5-1

|

885

|

830

|

|

|||||

|

TA11

|

Ti-811

|

Ti-811

|

960

|

905

|

|

|||||

|

TA15

|

|

BT2O

|

1010

|

865

|

|

|||||

|

TA18

|

GR9

|

OT4-1B

|

715

|

565

|

|

|||||

|

TB3

|

Ti-8823

|

BT32

|

1180

|

1000

|

|

|||||

|

TB5

|

Ti-15333

|

BT35

|

1060

|

920

|

|

|||||

|

TC4

|

GR5

|

BT6

|

1015

|

945

|

|

|||||

|

TC4ELI

|

GR23

|

BT6C

|

985

|

890

|

|

|||||

|

TC6

|

|

BT3-1

|

1000

|

890

|

|

|||||

|

TC8

|

|

BT8

|

1150

|

1040

|

|

|||||

|

TC11

|

|

BT9

|

1045

|

940

|

|

|||||

|

TC18

|

|

BT22

|

1230

|

1010

|

The main standards:

GJB2218-1994、GJB2505-1995、GJB494-1988、

GJB1538-1992、ASTMB265-2005、ASTMB381-2005 |

|||||

Titanium products

Typical products 1 - cathode roller titanium cylinder for lithium copper foil

|

Product technical indicators

|

|

|

|

Grinding ring grain size

|

Level 8.0

|

|

|

Spinning grain size

|

Level 13.0

|

|

|

Surface hardness HBW

|

105~120

|

|

|

UT inspection UTY

|

AA class (equivalent ≤φ0.8mm)

|

|

|

Product specifications/mm

|

D=φ2700~3600mm

H=680~930mm |

|

Microstructure of product after grinding (100×)

Product advantages

The technical indicators of the product are uniformly and stablyorganized,with a grain size difference of≤0.5 levels;

The surface hardness is uniform,and the difference in hardnessbetween different parts of the product is≤15HBW.

Application area

Copper Clad Laminate(CCL)and Printed Circuit Board(PCB)Lithium ion batteries (power lithium batteries,consumer lithiumbatteries,and energy storage lithium batteries).

Typical Products 2 - Marine Titanium Alloy Products

|

Material grade

|

Rpo,2 (MPa)

|

Rm (MPa)

|

A (%)

|

|

Ti-6AI-4V ELI

|

≥825

|

≥895

|

≥12

|

|

Ti-6Al-3Nb-2Zr-Mo

|

≥785

|

≥880

|

≥12

|

|

Ti-3Al-2.5V

|

≥485

|

≥650

|

≥15

|

Technical advantages

Advanced free forging and membrane forging technology enables the overall formation of irregular forgings,ensuring consistency in product performance indicators.

Adjust the organization and performance according to different servicere quirements to ensure product quality.

Application area

Ship pressure hull,pressure equalizing vessel,pump body,blades,heat exchanger,etc.

Hot Searches