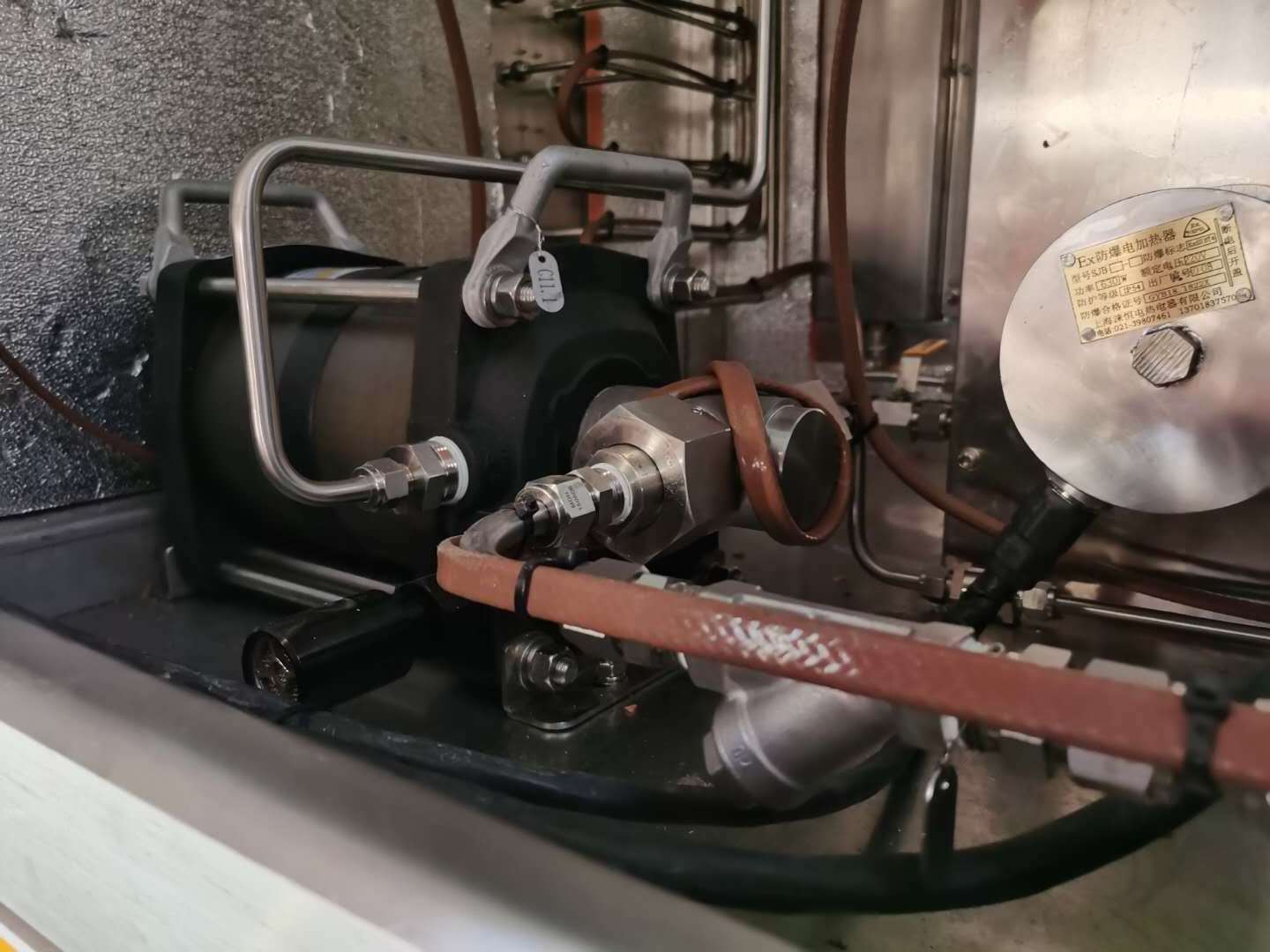

The pump is prepared for operation manually:

Connect supply lines (compressed air, suction and pressure lines).

Set air drive pressure.

Open compressed air supply slowly so that the high- pressure pump starts up .

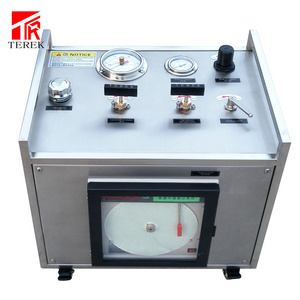

2. Build up pressure

The pump technology executes all the steps for pressure build-up automatically:

Automatic cycling of 4/2-way valve (spoolcycling valve)

by means of air pulses from the pilot valve (2/2-way valve) Suction of medium.

Optimum cycling conditions thanks to large cross- sections .

3. Achieve and hold pressure

The pump controls the processes of reaching and holding pressure.

Pump automatically stops operating when the

operating pressure is reached due to equilibrium of forces

Pressure is held.

Pressure holding phase with no energy consumption or heat generation .

Pump restarted automatically if operating pressure drops .

Pressure holding phase with no energy consumption or heat generation .

Pump restarted automatically if operating pressure drops .