- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

220V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LOM

-

Dimension(L*W*H):

-

1100*1100*1990mm

-

Weight:

-

300 KG

-

Certification:

-

CE Certificate

-

Processing Types:

-

Normal Pressure Filling

-

Bottle type:

-

PET Plastic Bottle

-

Usage:

-

Chemical

-

Function:

-

lipstick filling machine

-

Material:

-

SUS304

-

Filling speed:

-

depend on operation

-

Suitable for:

-

lipstick filling machine

Quick Details

-

Machinery Capacity:

-

20000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Beer

-

Filling Accuracy:

-

99%

-

Voltage:

-

220V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LOM

-

Dimension(L*W*H):

-

1100*1100*1990mm

-

Weight:

-

300 KG

-

Certification:

-

CE Certificate

-

Processing Types:

-

Normal Pressure Filling

-

Bottle type:

-

PET Plastic Bottle

-

Usage:

-

Chemical

-

Function:

-

lipstick filling machine

-

Material:

-

SUS304

-

Filling speed:

-

depend on operation

-

Suitable for:

-

lipstick filling machine

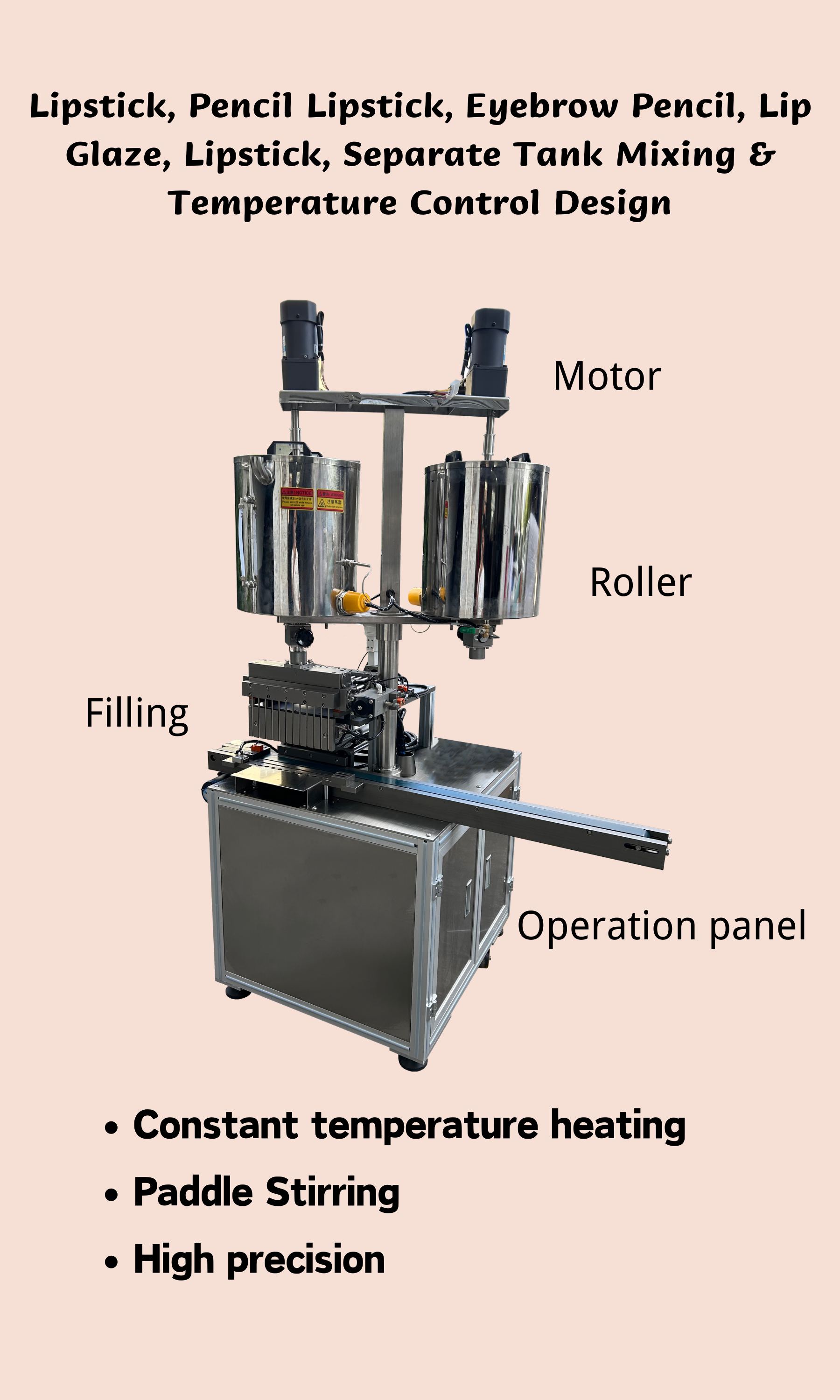

Product Information

Details

Parameters

|

Product Name

|

Lipstick filling machine

|

|

Voltage specification

|

380V/220V/50HZ

|

|

Power consumption

|

5.5kw

|

|

Production capacity

|

8s/mould

|

|

Table height

|

740mm(H)

|

|

Filling volume

|

1-15ml

|

|

Drum volume

|

20L(can be customised)

|

|

Mixing speed

|

0-180rpm

|

|

Machine size

|

1100*1100*1990mm

|

Application

Performance characteristics

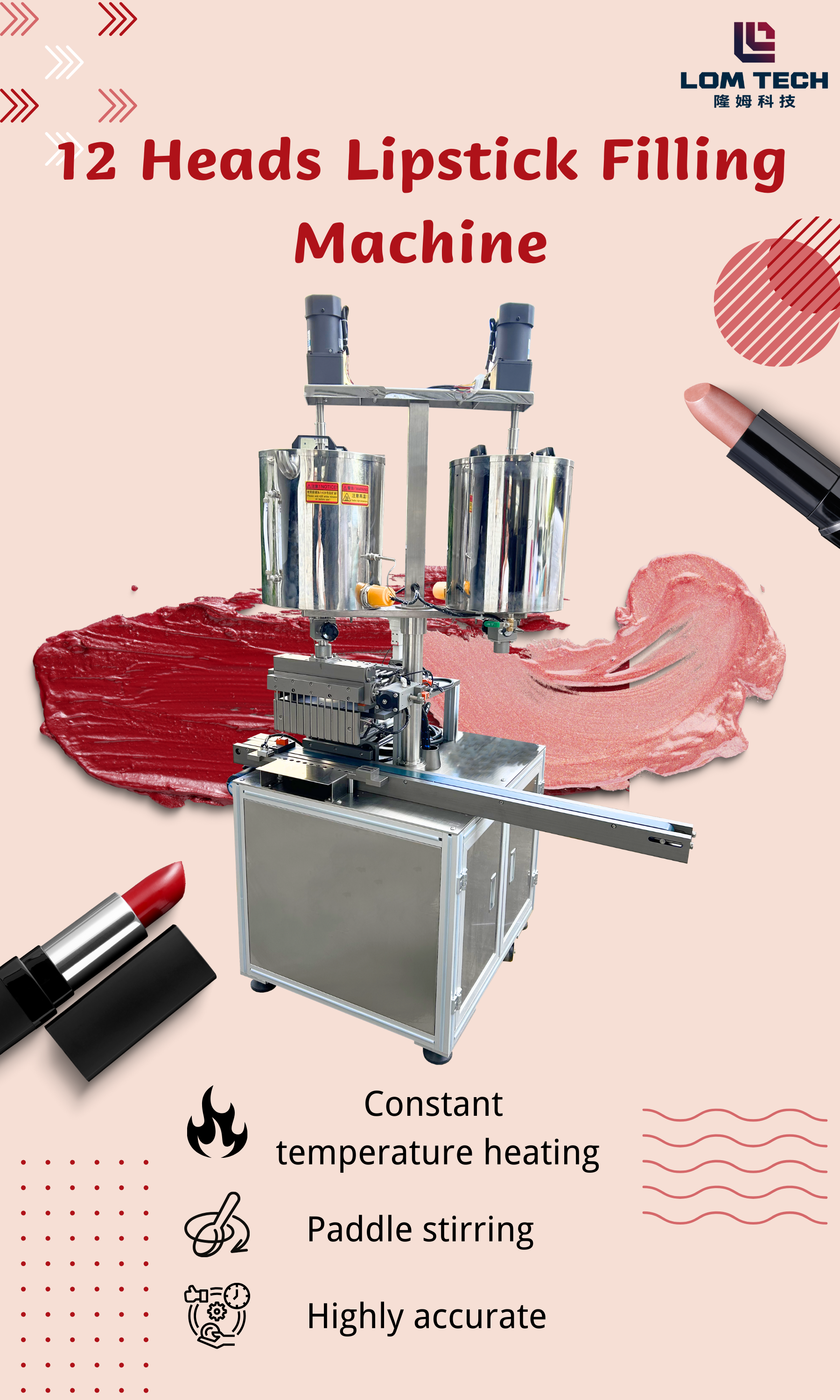

1. This product is designed for liquid cosmetics, such as: lipstick, pencil lipstick, eyebrow pencil, lip glaze, lipstick, etc.

2. Independent barrel mixing and temperature control design, to meet the diversified needs of raw materials.

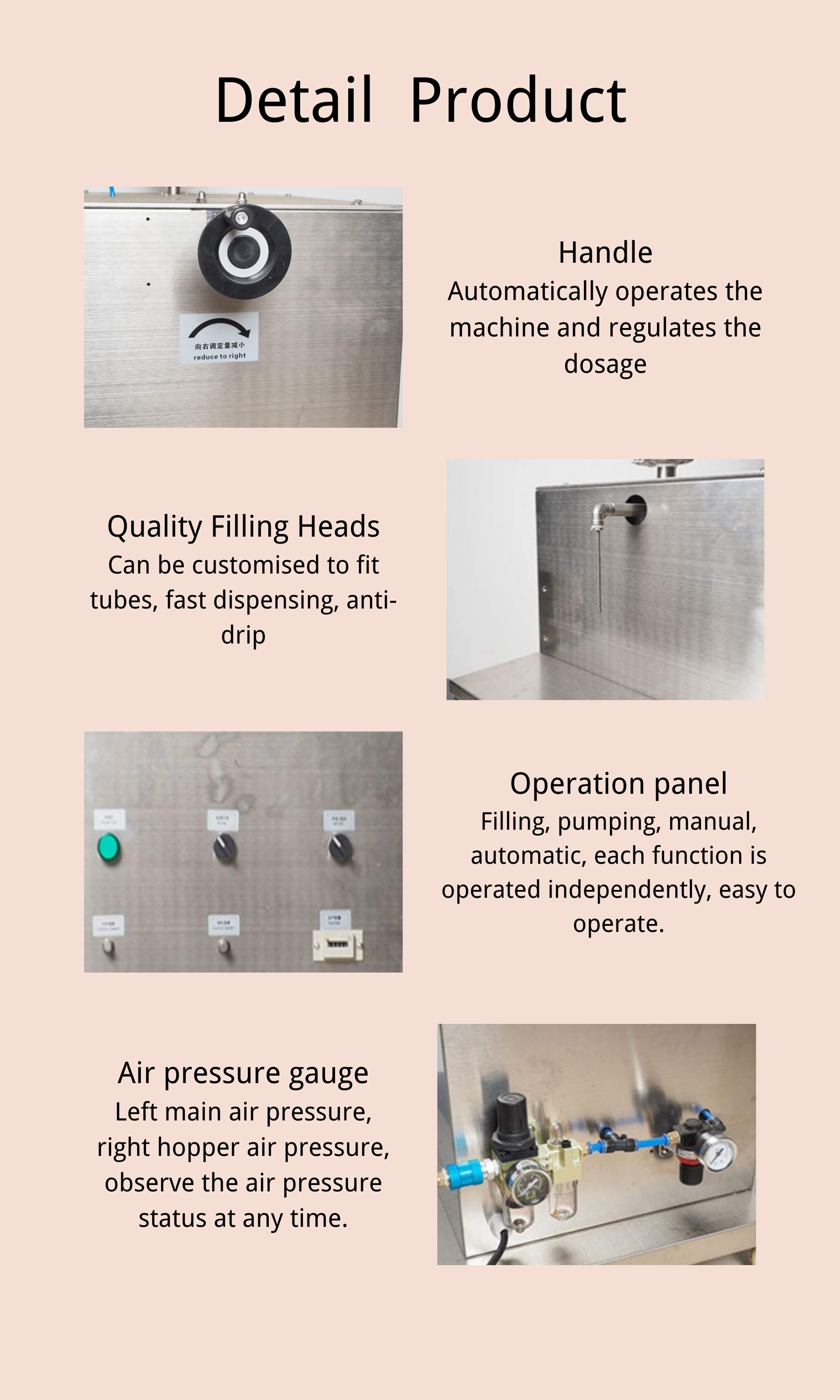

3. Adopting advanced automation technology (human-machine interface, OLC programme control), the parameters that need to be set

for the whole machine (time, temperature control settings) are all set by the human-machine interface, simplifying the system

operating procedures, and the overall performance is more stable.

3. The body is aluminium machine structure, platform are aluminium plane easy to clean

4. The system operation programme is simple, do not need to spend time to learn.

5. Each unit (barrel, pump, tube, nozzle) are controlled independently by intelligent temperature controller, temperature control

accuracy of ± 0.5 ℃, making the equipment easier to use.

1. This product is designed for liquid cosmetics, such as: lipstick, pencil lipstick, eyebrow pencil, lip glaze, lipstick, etc.

2. Independent barrel mixing and temperature control design, to meet the diversified needs of raw materials.

3. Adopting advanced automation technology (human-machine interface, OLC programme control), the parameters that need to be set

for the whole machine (time, temperature control settings) are all set by the human-machine interface, simplifying the system

operating procedures, and the overall performance is more stable.

3. The body is aluminium machine structure, platform are aluminium plane easy to clean

4. The system operation programme is simple, do not need to spend time to learn.

5. Each unit (barrel, pump, tube, nozzle) are controlled independently by intelligent temperature controller, temperature control

accuracy of ± 0.5 ℃, making the equipment easier to use.

About us

Packing & Delivery

FAQ

Q1: What is the working principle of the lipstick filling machine?

A1: The lipstick filling machine completes the process of filling lipstick liquid through a series of automated steps. First, the lipstick tube is placed in the proper position and the liquid is poured into the hopper of the filling machine. Next, start the machine and it will automatically extract and fill the liquid into each lipstick tube. Finally, remove the liquid-filled lipstick tubes and seal them.

Q2: How do I adjust the capacity of my lipstick filling machine?

A2: Lipstick filling machines are usually equipped with a capacity adjustment device, so you can adjust the capacity as needed.Usually, the way to adjust the capacity is by adjusting the flow rate of liquid. You can gradually increase or decrease the flow rate of the liquid to achieve the desired capacity according to the product requirements.

Q3: How to clean and maintain the lipstick filling machine?

A3: The lipstick filling machine may be contaminated with lipstick liquid residue after a period of use. Regular cleaning and

maintenance is necessary to ensure its proper functioning. Firstly, disconnect the power supply and then disassemble each part of the machine. Clean each part with detergent and a soft cloth and make sure there is no residue. Then, reassemble the machine and test it to make sure it is working properly.

Q4: What are some common failures of lipstick filling machines?

A4: Lipstick filling machine may encounter some common malfunctions, such as clogged pump valves, power failures, sensor failures and so on. When a malfunction occurs, you can first check if there are any clogged or loose parts, and clean and repair them in time. If the problem still exists, it is recommended to contact the manufacturer or professional maintenance personnel for repair.

Q5: How to choose the right lipstick filling machine?

A5: Choosing the right lipstick filling machine needs to consider several factors, such as production scale, budget and product requirements. You can consult professionals or manufacturers to understand the features and performance of different models and make a comparative assessment to choose the most suitable lipstick filling machine according to your needs.

A1: The lipstick filling machine completes the process of filling lipstick liquid through a series of automated steps. First, the lipstick tube is placed in the proper position and the liquid is poured into the hopper of the filling machine. Next, start the machine and it will automatically extract and fill the liquid into each lipstick tube. Finally, remove the liquid-filled lipstick tubes and seal them.

Q2: How do I adjust the capacity of my lipstick filling machine?

A2: Lipstick filling machines are usually equipped with a capacity adjustment device, so you can adjust the capacity as needed.Usually, the way to adjust the capacity is by adjusting the flow rate of liquid. You can gradually increase or decrease the flow rate of the liquid to achieve the desired capacity according to the product requirements.

Q3: How to clean and maintain the lipstick filling machine?

A3: The lipstick filling machine may be contaminated with lipstick liquid residue after a period of use. Regular cleaning and

maintenance is necessary to ensure its proper functioning. Firstly, disconnect the power supply and then disassemble each part of the machine. Clean each part with detergent and a soft cloth and make sure there is no residue. Then, reassemble the machine and test it to make sure it is working properly.

Q4: What are some common failures of lipstick filling machines?

A4: Lipstick filling machine may encounter some common malfunctions, such as clogged pump valves, power failures, sensor failures and so on. When a malfunction occurs, you can first check if there are any clogged or loose parts, and clean and repair them in time. If the problem still exists, it is recommended to contact the manufacturer or professional maintenance personnel for repair.

Q5: How to choose the right lipstick filling machine?

A5: Choosing the right lipstick filling machine needs to consider several factors, such as production scale, budget and product requirements. You can consult professionals or manufacturers to understand the features and performance of different models and make a comparative assessment to choose the most suitable lipstick filling machine according to your needs.

Hot Searches