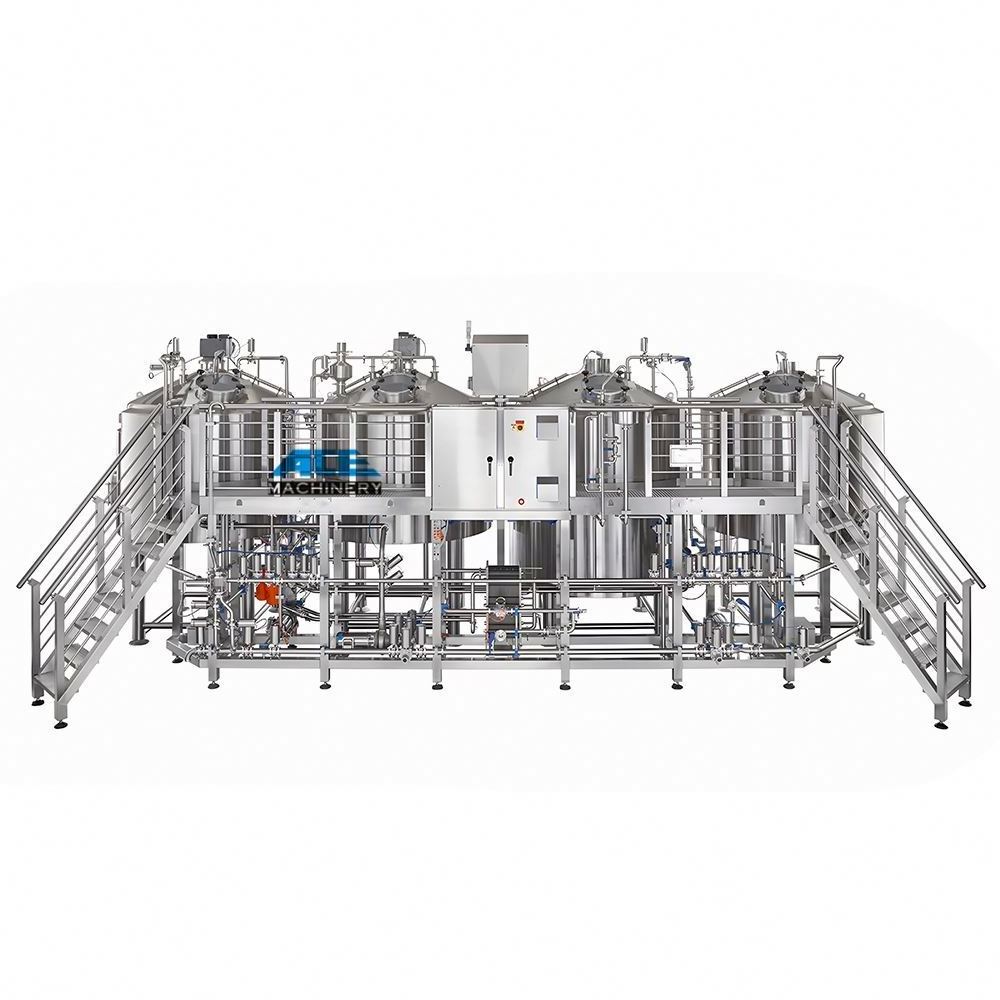

A typical two-vessel Combination Mash Lauter Tuns are the first combination vessel in these brewhouses line ups.Next inline is the combination of the Kettle and Whirlpool tanks.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Customized

-

Dimension(L*W*H):

-

User Requirements

-

Weight:

-

200 KG

-

Material:

-

Stainless Steel 304 or 316L

-

Capacity:

-

300L-10,000L

-

Capacity in BBL:

-

1~120bbl

-

Keyword:

-

Beer Brewing Turnkey Brewery price

-

Technology Advantage:

-

PU insulation, dimple jacket, cooling system ect

-

Controlling System:

-

Instrument panel controller or PLC controller

-

Thickness of Tanks:

-

3mm for interior shell/2mm for exterior shell

-

Usage:

-

Beer Home,Stainless Steel Beer Fermenter,MASHING MALT

-

Heating method:

-

Steam ,Electric,Gas

-

Tags:

-

all in one/micro brewery/Fermenter/Beer

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ACE

-

Voltage:

-

220V 380v 415V 480V Customized

-

Power:

-

Customized

-

Dimension(L*W*H):

-

User Requirements

-

Weight:

-

200 KG

-

Material:

-

Stainless Steel 304 or 316L

-

Capacity:

-

300L-10,000L

-

Capacity in BBL:

-

1~120bbl

-

Keyword:

-

Beer Brewing Turnkey Brewery price

-

Technology Advantage:

-

PU insulation, dimple jacket, cooling system ect

-

Controlling System:

-

Instrument panel controller or PLC controller

-

Thickness of Tanks:

-

3mm for interior shell/2mm for exterior shell

-

Usage:

-

Beer Home,Stainless Steel Beer Fermenter,MASHING MALT

-

Heating method:

-

Steam ,Electric,Gas

-

Tags:

-

all in one/micro brewery/Fermenter/Beer

Automation Create New Business By Ale,Lager,Ipa Beer Brewery Machine For Hotel,Pub,Barbecue,Bar 10Bbl

Custom Made 300L- 10,000L

Brewing equipment

, 20 Years Of Experience. Reasonable Price And Best Service, CE Certificated Products. Please

contact us for the offer.

We Can Make The Brewing Equipment For Beer, Wine, Sparkling Wine, Whiskey, Gin, Brandy, Rum Etc The Equipment Capacity From 300l To 10,000l.

Beer Equipment:

Including The Brew house, Fermenter, Brite Tank, CIP Trolley Etc;

Wine Equipment:

Including The Red Wine/White Wine/Sparkling Wine Tank, Floating Lid Wine

Tank Whole Wine Distillation Equipment:

Including The Rum/Whiskey/Brandy/Gin/Vodka Stills

Products Description

The function of a beer brew house is processing the grist and water into the wort, which is ready for fermentation. We offers varying levels of automation and customization of two, three and four vessel brew house configurations. We focus on the design and structure of the brew house, which is the reason why we have to confirm all drawings of the equipment at the first beginning. All auxiliary equipment can be added or removed according to your requirements. Platform can be chosen.

2-Vessel Main Features:

3-Vessel Main Features

A three-vessel brewhouse is hybrid system that incorporates at least one combination vessel and two dedicated process vessels.

4-Vessel Main Features :

A typical four-vessel brewhouse will include a Mash tun, Lauter Tun, Kettle and Whirlpool. Each of these tanks is dedicated to performing a single process, and is designed differently than similar vessel used for performing multiple processes.

Beer Fermentation Tank

Description:

• Beer Fermentation Tank has 100L and 30,000L and otherpecifications, according to the actual requirment of customers.

• Cone bottom shape, cooling jacket using dimple jacketjacketed outside covered with insulation, thermal insulationmaterial for polyurethane (cold).

• Connector using tri-clamp, inner tank using SS304 or S316L the inner surface mirror polishing Ra≤0.4um-0.6um. Outersurface can be polished, wiredrawn, sandblasted according tocustomers requirement.

|

Stainless steel beer fermenter tank

|

|

|

|

Structure:

|

1.Volume from 100L-30,000L,could be customized according to customer needs.

|

|

|

|

2.Material use sanitary stainless steel.

|

|

|

|

3.Three layer structure:Inner body,Jacket and isolation.Isolation layer filled with insulation material.

|

|

|

|

4.Inner wall fineness less than 0.6um,outside finish could be matt or mirror polish

|

|

|

|

5.Conical bottom shape,cooling jacket could adopt dimple jacket,arched and corrugated access jacket.

|

|

|

|

6.All pipes are all ISO or DIN sanitaty pipe,internal and external adopt food grade mirror polish

|

|

|

|

7.PLC control system,which could achieve automatic,semi automatic control,to ensure the accurately and effectively of parameters

and experimental results. |

|

|

Parts(optional):

|

1.Manhole 2.Aseptic breather 3.Thermometer(As customer request) 4.CIP Spray ball 5.Bacterial access port 6.Agitator 7.Adjustableleg 8.Jacket(Dimple or full jacket as customer request)

|

|

Advantage:

1. Highly Competitive Price, More Than 10 Years Production And Manufacturing Experience

2. Iso9001, Ce (2014/68 / Eu) Ped Certification

3. Strictly Quality Control, Meet The European Quality Standard, Take 3 Times Water Pressure Test During Production.

4. Accept Customized, Professional Engineers Will Provide Design Solutions For You

5.Use High-Quality 304 Stainless Steel, Ensure The Thickness Of The Material

6. Dimple Plate Cooling Jacket, Better Cooling Effect And Longer Service Life

7. Equipped With Safety Valve, Water-Sealed Pressure Valve, To Ensure The Safe Operation Of The Fermentation Tank

Customer cases: we have customer cases in the United States, Japan, South Korea, Australia, the Philippines, the United Kingdom, Mexico, Spain Singapore and Canada.

Serving Tank

Description:

The bright tanks are cans for storing live beer. After the beer is fermented and matured, the yeast and another turbidity in the fermentation broth need to be filtered to make the wine clear and bright. After the fermentation broth is filtered, it is called "bright beer". Let the packaging department bottling into beer finished products. Sake jars are used to hold sake.

In most breweries, the beer will be filtered after leaving the larger container and sent into bright tanks. If you want to force carbonation of bright beer, the beer can be carbonated in a fermentation tank or storage tank. In this case, the beer should be completely filled with carbonic acid to reach the bright tank.

|

Parameter of Bright Beer Tank:

|

|

|

|

Effective volume

|

100L-10000L

7BBL~30BBL 1HL~100HL |

|

|

Type

|

veritical type, easy cleaning

horizontal type, space saving |

|

|

Design pressure

|

0.3Mpa

|

|

|

Working pressure

|

0.15Mpa

|

|

|

Materials

|

304 Stainless Steel

316 Stainless Steel Option |

|

|

Control System

|

CIP arm and 360° spary ball

|

|

Mash tun

Description:

Mash Tun is a brewhouse vessel used for mixing the ground malt (grist) with temperature-controlled water. This is called “mashing”

and the porridge-like result is called the “mash.” See mash and mashing. The mash is held at a predetermined temperature and time

(e.g., at 65°C for 1 h) until the malt starches convert to sugars, and the dissolved malt sugars (wort) are rinsed into the kettle

where hops are added. The mash tun is a single vessel where the mashing and wort runoff take place in the same vessel. It is

predominantly used for brewing ales and other top-fermented beers, particularly in the UK, using a single-temperature infusion

mash.

|

Stainless Steel Mash Tun

|

|

|

|

Structure

|

• Can be customized according to customer's requirements• with jacket cooling zones or coil inside the tank

• with PU foram insulation to keep warm • the width and height can be design accroding to customer requirements • 304 Polished and Brushed Stainless and Polished Standard Features: • Agitator,CIP ball,thermometer,thermowell etc. • Clamps and gaskets • Stainless steel legs with stainless leveling footpads • Interior shell: 304 stainless steel • Exterior shell: 304 stainless steel • Interior and exterior finish polished to a sanitary finish • Interior finish pickled and passivated • Fully welded exterior shell |

|

|

Working capacity

|

1bbl/2bbl/3.5bbl/4bbl/5bbl/7bbl/10bbl/15bbl/20bbl/25bbl/30bbl/40bbl/50bbl/60bbl/90bbl/100bbl/120bbl standard size

|

|

Wine Fermentation Tank

Description:

1. Used as storage and fermentation tank in wine industries

2. Volume from 50L-30000L, could be customized according to customer needs

3. Material use sanitary stainless steel.

4. Conical bottom shape, cooling jacket could adopt dimple jacket, arched and corrugated access jacket.

5. PLC/PID control system, which could achieve automatic, semi-automatic control, to ensure the accurately and effectively of

parameters and experimental results.

|

Shape

|

Cone top and bottom

|

|

Cooling jacket

|

Glycol jacketed on body

|

|

Manway

|

Top round manway+Side lower manway for spent grain

|

|

Accessories

|

CIP armBottom drain port

Thermometer/sample valve/thermowell on body part |

|

Optional choice

|

Agitator can be added in case you will mix the wine during fermentings

|

|

Application

|

The fermenter tank is applied to distillery,winery and brewery

|

Stills

Description:

1. Is easy to operate and use, easy to clean and occupies a small area.

2. High safety, high work efficiency, long service life, low energy consumption, good quality and low price.

3. Provide customized services, technical and drawing support

4. Can steam heating, electric heating (direct and indirect type) or direct fire heating

5. Apply to whiskies, gins, tequilas, rums and bourbons etc

6. Efficient CIP spraying ball for 360-degree cleaning.

7. Italy brand gear box, NEMA standard for North American Market

8. Explosion proof motor, be CE, UL, CSA approved

Certifications

FAQ

|

Q

|

Are you trade or manufacturer?

|

|

|

|

|||

|

A

|

We are a factory with an international sales company specialized in support for global distributors.

|

|

|

|

|||

|

Q

|

Can you provide instant technical consulting services?

|

|

|

|

|||

|

A

|

We are able to discuss technical details and offer suggestions over the phone in English.

You can get the answers in minutes, instead of days. |

|

|

|

|||

|

Q

|

What's the difference between Ready-To-Ship and Customized products?

|

|

|

|

|||

|

A

|

Some of RTS standard products are in stock and ready to ship in 2-3 days.

We can also quick design and make the drawings for customer requirements, then begin the production. |

|

|

|

|||

|

Q

|

What is the payment terms?

|

|

|

|

|||

|

A

|

We accept Alibaba Trade Assurance Order, also can T/T and L/C.

|

|

|

|

|||

|

Q

|

How to choose the shipment way?

|

|

|

|

|||

|

A

|

It is according to the order quantity, delivery time, costs and customs policy etc. (Or decide by customers)

|

|

|

|

|||

|

Q

|

How about the after-sales service?

|

|

|

|

|||

|

A

|

Fast after-sales support. Our products have a one-year warranty and free permanent consulting services.

|

|

|

|

|||

Hot Searches