- Product Details

- {{item.text}}

Quick Details

-

Mould Cavity:

-

2cavity

-

Blower Dimensions:

-

1450*600*1700mm*2

-

Heater Dimensions:

-

2100*700*1400mm

-

Bottle Neck:

-

18-120mm

-

Bottle Size:

-

100-2500ml

-

High Air Compressor:

-

2.0m3/3.0mpa

-

Low Air Compressor:

-

1.6m3/1.0mpa

-

Mould Chiller:

-

3HP

Quick Details

-

Place of Origin:

-

China

-

Product name:

-

PET Bottle Blowing Machine

-

Key words:

-

pet blowing machine

-

Mould Cavity:

-

2cavity

-

Blower Dimensions:

-

1450*600*1700mm*2

-

Heater Dimensions:

-

2100*700*1400mm

-

Bottle Neck:

-

18-120mm

-

Bottle Size:

-

100-2500ml

-

High Air Compressor:

-

2.0m3/3.0mpa

-

Low Air Compressor:

-

1.6m3/1.0mpa

-

Mould Chiller:

-

3HP

Semi automatic Two Blower One Heater pet blowing machine with 2 cavity

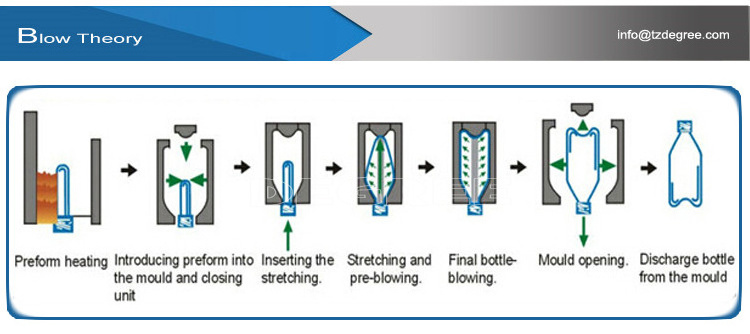

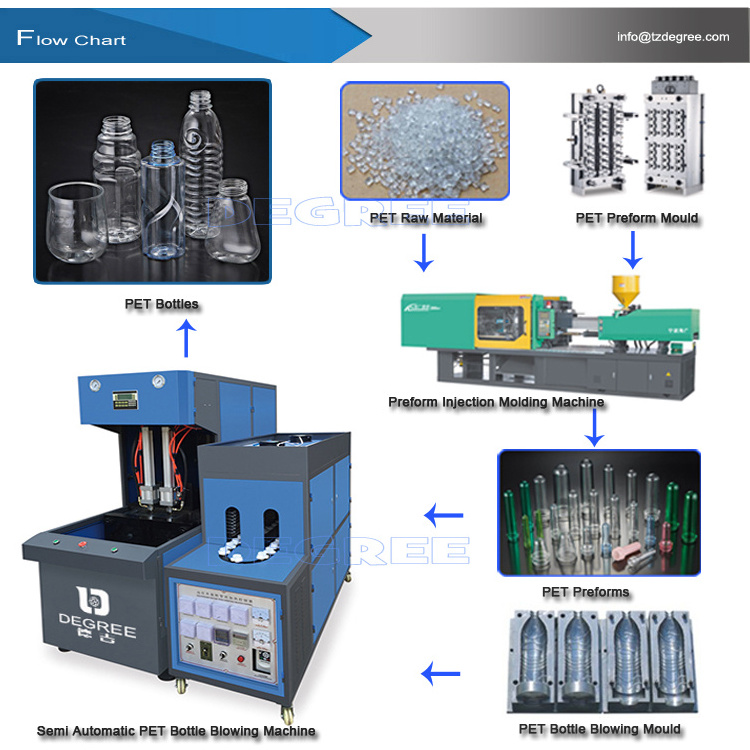

What is pet blowing machine?

It is one kind of two step stretch type bottle making plant.

It i s suitable to produce plastic bottles based on PET raw material.

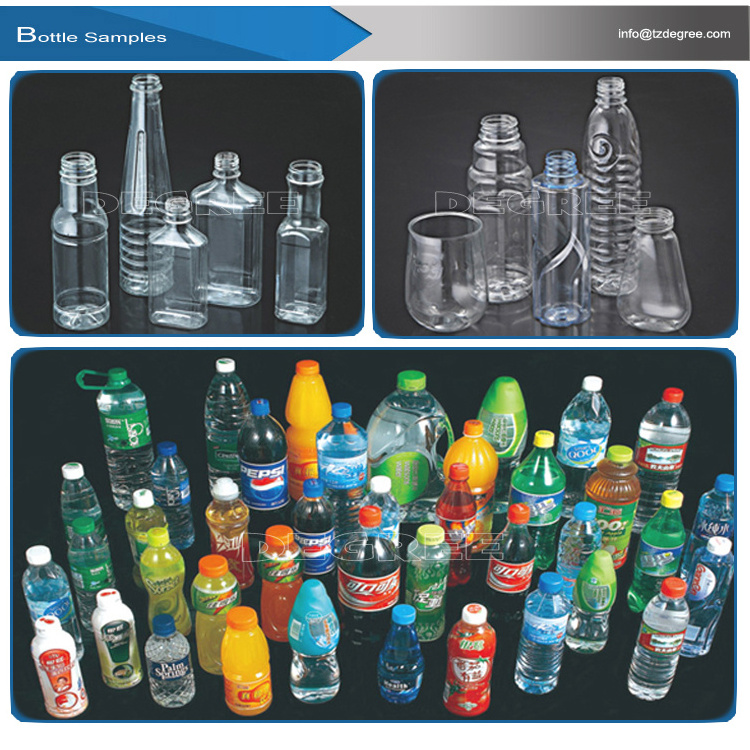

It is widely used to produce carbonated soft drinks

bottles, mineral water bottles, cooking oil bottles, medicine bottles, cosmetic bottles, wide mouth Jars and hot filling juice bottles etc

Machine Specification:

|

Model |

DE G-3L-II (Two Blower & One Heater) |

|

Clamping Force |

100KN |

|

Clamping Stroke |

160 MM |

|

Max. Stretching Stroke |

360MM |

|

Number of Cavities |

2 Cavity |

|

Theoretical Output |

1800 BPH(500ml) |

|

Max. Mold Thickness |

300MM |

|

Voltage Standard |

380v/3PH/50Hz or special order |

|

Number of Heating Zone |

4 Sections |

|

Total Power (Full Loaded) |

15 KW |

|

Max. Container Volume |

2L |

|

Neck Diameter Range |

18-120mm |

|

Max. Container Diameter |

360mm |

|

Max. Container Height |

380mm |

|

Low Air compressor |

10Bar |

|

High Air compressor |

30-40Bar |

|

Blow molding machine |

145 0 *60 0 *170 0mm *2 |

|

Preform Heater |

210 0 *70 0 *140 0mm |

|

Net Weight |

1300kgs |

Machine Features:

DEG -3L -II blow molding machine (two blower, one heater) is used to produce 0.1-2L cooking oil bottles, mineral water bottles, carbonated bottles, soft drinks bottle, detergent bottles etc .

1. Produce bottle from 0.1L to 2L (2 cavity)

2. Output capacity up to 20 00 bph for 0.5L using two-cavity blow ing mold ( two blower & one heater)

3. Advanced PLC control system with a use-friendly panel and time-control precision of PLC up to

0.01second

4. Equipped with special designed air storage unit

5. Using Infrared preform heater

6. Independent Temperature Control for different heating lamp to get ideal preform heating results

7. Heating lamps are adjustable in directions to suit various preforms.

8. Operated only by one person without special training.

9. Simple installation & start up adjustment.

10. Waste rate of finished bottle is less than 0. 1 %

1.Installation Services

Installation Services are available with all new machine purchases. We will provide the technical know-how for your operation smooth transition and support for installing, debugging, operation of the machine, it will indicate you how to use this machine well.

2.Traning Services

We can train your staff to use our machine properly.It means that we offer Customers Training, teaching how to use the systems most efficiently and safely as well as how to maintain optimal operational productivity.

3.After Sales Service

We offer the Preventative Maintenance and After Sales Service. For we strongly feels about the importance of supporting our customers and the product solutions we provide.Consequently we offer comprehensive maintenance options to prevent equipment issues before they become problems. Also we offer one year guarantee period and lifelong technical support!