Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Anda

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

25m*2m*2.5m, 25M*2M*2.5M

-

Power (kW):

-

37

-

Weight:

-

10000 KG

-

motor power:

-

37w

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Working speed:

-

according to extrusion line

-

Inverter:

-

ABB Brand

-

Temperature control:

-

Omron Brand

-

Capacity:

-

120~3500KG/H

-

Raw material:

-

PVC Powder

-

Material:

-

PP PE LDPE HDPE

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

132:1

-

Screw Speed (rpm):

-

72 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Anda

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

25m*2m*2.5m, 25M*2M*2.5M

-

Power (kW):

-

37

-

Weight:

-

10000 KG

-

motor power:

-

37w

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Working speed:

-

according to extrusion line

-

Inverter:

-

ABB Brand

-

Temperature control:

-

Omron Brand

-

Capacity:

-

120~3500KG/H

-

Raw material:

-

PVC Powder

-

Material:

-

PP PE LDPE HDPE

Products Description

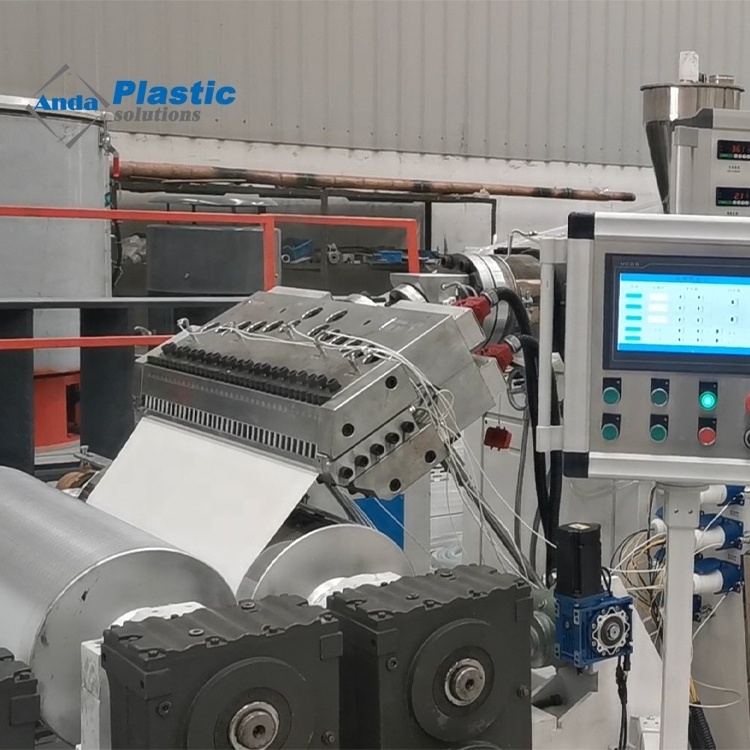

Pvc Edge Band Tape Extrusion Production Line With Calender Cooling

PVC edge band production line with Calender Cooling is used to produce PVC edge band with different width, section shape and thickness. The surface of PVC edge band can be treated by three color printing & coated with glossy oil, or by heat transfer printing.

Pvc Edge Band Tape Extrusion Production Line

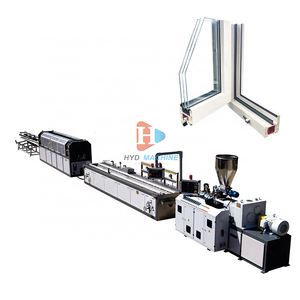

1.Mixer+ PVC granulating machine+double screw extruder+printing machine

Process: First you need mix raw material together by PVC mixer, second make granule by granulating machine, and then Use single screw extruder(Sj45 or SJ65 single screw extruder) to get edge band, then use printing machine to get glossy surface or wooden design and etc.

Process: First you need mix raw material together by PVC mixer, second make granule by granulating machine, and then Use single screw extruder(Sj45 or SJ65 single screw extruder) to get edge band, then use printing machine to get glossy surface or wooden design and etc.

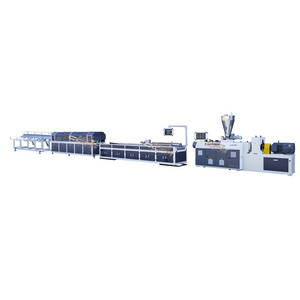

2. Mixer+Double screw extruder+ printing machine

Process: First mix raw material together by mixer, and the use double screw extruder(SJSZ51/105 or SJSZ55/110) to produce egde band, final step is to print color or make edge band glossy.

Process: First mix raw material together by mixer, and the use double screw extruder(SJSZ51/105 or SJSZ55/110) to produce egde band, final step is to print color or make edge band glossy.

3. Three calender system+ printing machine+cutting machine

First mix raw material, and then use three calender system to produce big width edge band sheet, and then print colors on the edge band, finally, cut pvc edge band sheet into specific width like 19mm, 20mm etc...

First mix raw material, and then use three calender system to produce big width edge band sheet, and then print colors on the edge band, finally, cut pvc edge band sheet into specific width like 19mm, 20mm etc...

Final Products

Product Details

1.Pvc Edge Band Tape Extrusion Production Line--Extruder Machine

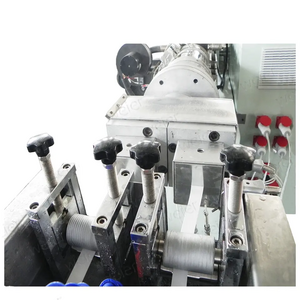

2.Pvc Edge Band Tape Extrusion Production Line --Glue machine

3.Cutting Machine

Machine parameters

:

|

Model

|

160

|

400

|

750

|

|

Extruder

|

51/105

|

55/110

|

65/132

|

|

Max width(mm)

|

160

|

400

|

750

|

|

Main motor power (kw)

|

18.5

|

22

|

37

|

|

Output(t)

|

1.5-2

|

2-2.5

|

3.5-4

|

Anda main products:

UPVC window and door profile production line

PVc edge band production line

WPC/PVc louver panel production line

PVC marble board production line

PS louver panel production line

PVC edge band production line with calender cooling

Vinyl siding panel production line

PVC fluted panel production line

PVC ceiling panel making machine

PVC wall panel production line

WPC wall panel production line

PVC marble sheet extrusion machine production line

Double color UV printing machine, transfer printing machine, lamiantion machines for PVC ceiling panel,wall panel,PVC door panels

ASA composited PVC roof tile extrusion machine and production line

PVC edge band production line with double screw extruder and single screw extruder

PVC profile extrusion machine and production line

PVC pipe extrusion machine and production line

PE PPR pipe extrusion machine and production line

PVC pulverizer machine

PE pulverizer machine

hot and cooling PVC mixer for compounding

PVc edge band production line

WPC/PVc louver panel production line

PVC marble board production line

PS louver panel production line

PVC edge band production line with calender cooling

Vinyl siding panel production line

PVC fluted panel production line

PVC ceiling panel making machine

PVC wall panel production line

WPC wall panel production line

PVC marble sheet extrusion machine production line

Double color UV printing machine, transfer printing machine, lamiantion machines for PVC ceiling panel,wall panel,PVC door panels

ASA composited PVC roof tile extrusion machine and production line

PVC edge band production line with double screw extruder and single screw extruder

PVC profile extrusion machine and production line

PVC pipe extrusion machine and production line

PE PPR pipe extrusion machine and production line

PVC pulverizer machine

PE pulverizer machine

hot and cooling PVC mixer for compounding

Main Features

1.World famous brand inverter--ABB, stable and reliable.

2.World famous brand controller--Schneider, reliable performance.

3.World famous brand temperature controller--Omron, precision temperature control, reliable and durable.

4.Automatically low power consumption: minimum total production line consumption is 25kw/hour.

5. Economical price, which is suitable for large scale investment.

2.World famous brand controller--Schneider, reliable performance.

3.World famous brand temperature controller--Omron, precision temperature control, reliable and durable.

4.Automatically low power consumption: minimum total production line consumption is 25kw/hour.

5. Economical price, which is suitable for large scale investment.

Hot Searches