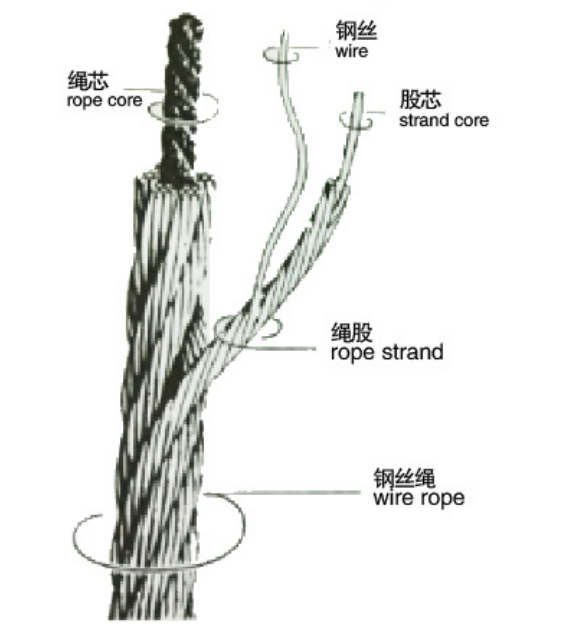

Every wire rope used for rigging and lifting is comprised of three main components:

1. Metal wires

2. Strands formed by the individual wires

3. A fiber or steel core around which the strands are laid

Variations in these three components account for nearly all the different types of wire rope cable, as well as the different benefits they offer.

The wires of a cable rope are the smallest component and are twisted together to form individual strands. Wires can be constructed

in a variety of materials and grades, all affecting the properties offered by the cable rope. These materials include:

* Steel

* Iron

* Stainless Steel

* Monel

* Bronze

These different materials and grades affect the cable rope’s strength, bending fatigue resistance, corrosion resistance, wear

resistance, and curve of the wire rope.

- Product Details

- {{item.text}}

Quick Details

-

Grade:

-

High carbon steel

-

Place of Origin:

-

HEB

-

Model Number:

-

SR

-

Brand Name:

-

Long Zhuo

-

Product name:

-

Galvanized Steel Security Cable Wire Rope

-

Diameter:

-

1mm-16mm

-

Structure:

-

19 Wire Strand Protection

-

Material:

-

High Carton Steel

-

Usage:

-

Construcion

-

Surface treatment:

-

Black Painting

-

Wire Gauge:

-

1-50MM

-

Tensile strength:

-

1370-2160MPA

-

Length:

-

Customized Length

-

Technique:

-

Cold Rolled Hot Rolled

Quick Details

-

Steel Grade:

-

High carbon steel

-

Type:

-

Steel

-

Tolerance:

-

±1%

-

Grade:

-

High carbon steel

-

Place of Origin:

-

HEB

-

Model Number:

-

SR

-

Brand Name:

-

Long Zhuo

-

Product name:

-

Galvanized Steel Security Cable Wire Rope

-

Diameter:

-

1mm-16mm

-

Structure:

-

19 Wire Strand Protection

-

Material:

-

High Carton Steel

-

Usage:

-

Construcion

-

Surface treatment:

-

Black Painting

-

Wire Gauge:

-

1-50MM

-

Tensile strength:

-

1370-2160MPA

-

Length:

-

Customized Length

-

Technique:

-

Cold Rolled Hot Rolled

Product Overview

Galvanized Steel Security Cable Wire Rope

The use of wire rope, sometimes called steel cable, steel sling rope, or steel rigging wire, is extremely popular in the material handling industry. Wire ropes come in a huge variety of designs and constructions, all suited for different lifting applications.

Each type of wire rope has benefits and drawbacks. What all wire ropes have in common however, is that they are made up of steel wires which form individual stands. These strands are laid in a helical pattern around a fiber or steel core to form the rope.

Different wire configurations and strand structures offer specific benefits to fit virtually any rigging application.

Each type of wire rope has benefits and drawbacks. What all wire ropes have in common however, is that they are made up of steel wires which form individual stands. These strands are laid in a helical pattern around a fiber or steel core to form the rope.

Different wire configurations and strand structures offer specific benefits to fit virtually any rigging application.

Anatomy of Steel Rope

Product Specification

The classification of a wire rope is based on the number of strands, as well as the number of wires in each strand. Below is a table of the most common wire rope configurations arranged in specific classifications.

|

Classification

|

Outer Strands

|

Wires / Strands

|

|

6 x 7

|

6

|

3-14

|

|

6 x 19

|

6

|

15-26

|

|

6 x 36

|

6

|

27-49

|

|

6 x 61

|

6

|

50-74

|

|

6 x 91

|

6

|

75-109

|

|

7 x 19

|

7

|

15-26

|

|

7 x 36

|

7

|

27-49

|

|

8 x 7

|

8

|

3-14

|

|

8 x 19

|

8

|

15-26

|

|

8 x 36

|

8

|

27-49

|

|

8 x 61

|

8

|

50-74

|

Steel Rope Strand Patterns

Wire ropes can be constructed using one of the five main strand patterns or a combination of two or more of the basic strand patterns. The wire rope strand pattern refers to the number of wires per layer, the number of layers, and the size of the wires.The strand pattern of a wire rope is a very important determining factor when it comes to choosing the correct wire rope for your specific rigging application. The five basic strand patterns are:

* Single Layer: This strand pattern is constructed by laying several wires around a center wire of the same diameter.

* Filler Wire: This strand pattern is constructed by laying two layers of same sized wires around a center. The outer layer will have 2x the amount of wires than the inner layer. In the valleys of the inner wires are small filler wires to fill in the gaps

between the inner and outer layers.

* Seale: A layer of same sized wires smaller than the center wire is laid around the center. The outer layer consists of the same amount of wires as the inner layer but bigger in size. The outer wires lay in the valleys of the inner wires.

* Warrington: This strand pattern consists of two wire layers. A layer of wires is laid around a same sized center wire to form the inner layer. The outer layer is formed by laying wires of alternating sizes, big and small, around the inner layer. The larger outer wires lay in the valleys of the inner wires and the smaller outer wires lay on the crowns of the inner wires.

* Combination: A combination wire rope strand pattern is constructed by combining two or more of the strand patterns above to form a single unique strand pattern.

* Single Layer: This strand pattern is constructed by laying several wires around a center wire of the same diameter.

* Filler Wire: This strand pattern is constructed by laying two layers of same sized wires around a center. The outer layer will have 2x the amount of wires than the inner layer. In the valleys of the inner wires are small filler wires to fill in the gaps

between the inner and outer layers.

* Seale: A layer of same sized wires smaller than the center wire is laid around the center. The outer layer consists of the same amount of wires as the inner layer but bigger in size. The outer wires lay in the valleys of the inner wires.

* Warrington: This strand pattern consists of two wire layers. A layer of wires is laid around a same sized center wire to form the inner layer. The outer layer is formed by laying wires of alternating sizes, big and small, around the inner layer. The larger outer wires lay in the valleys of the inner wires and the smaller outer wires lay on the crowns of the inner wires.

* Combination: A combination wire rope strand pattern is constructed by combining two or more of the strand patterns above to form a single unique strand pattern.

Hot Searches