- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15-70Kw depends on capacity

-

Dimension(L*W*H):

-

20-100M2 depends on capacity

-

Weight:

-

250 KG

-

Equipment Material:

-

SUS304 or Red Copper M2 for outer shell

-

Thickness of Tanks:

-

3mm for inner container/2mm for outer shell

-

Color Available:

-

Mirror SUS, Luxury red copper

-

Heating:

-

Electric/steam

-

Heat Insulation:

-

Polyurethane or Rockwool with Thickness=80mm

-

Inner Polishing Precision:

-

0.4 Micrometer

-

Volume Design:

-

Properly according to the capacity request

-

Controlling System:

-

PLC; HMI or Touch Panel

-

Plants Type:

-

Turnkey or Customerized

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tiantai or OEM

-

Voltage:

-

3phase/380v/50Hz or customized

-

Power:

-

15-70Kw depends on capacity

-

Dimension(L*W*H):

-

20-100M2 depends on capacity

-

Weight:

-

250 KG

-

Equipment Material:

-

SUS304 or Red Copper M2 for outer shell

-

Thickness of Tanks:

-

3mm for inner container/2mm for outer shell

-

Color Available:

-

Mirror SUS, Luxury red copper

-

Heating:

-

Electric/steam

-

Heat Insulation:

-

Polyurethane or Rockwool with Thickness=80mm

-

Inner Polishing Precision:

-

0.4 Micrometer

-

Volume Design:

-

Properly according to the capacity request

-

Controlling System:

-

PLC; HMI or Touch Panel

-

Plants Type:

-

Turnkey or Customerized

200L 2HL Red copper electric combined 3 vessel 200 liter brew kettle hotel brewery

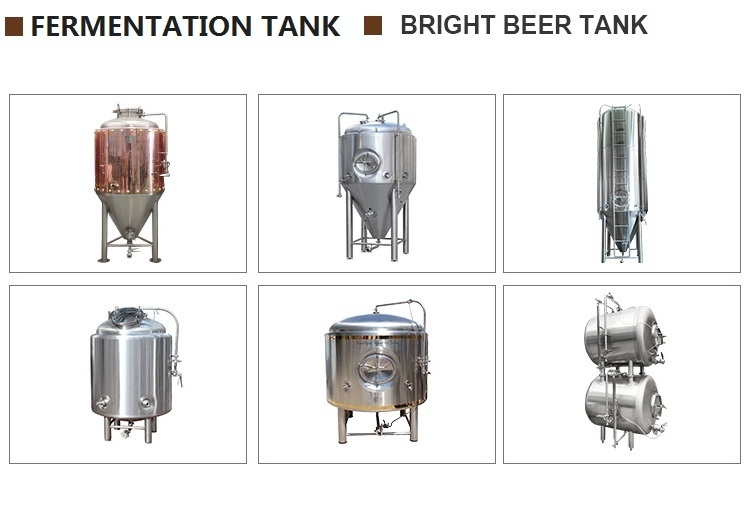

1.Production Description

200L 2HL Red copper electric combined 3 vessel 200 liter brew kettle hotel brewery is usually for university lab, home, small brewpubs or trial in breweries. It is a flexible system to do beer recipe test for breweries. If you are just a beer hobbyist, this 200L system is an economic investment to start your brewing career. The 200L pilot system is mainly composed of brewhouse system and fermentation system. Brewhouse system is 3 combined v essels brewhouse; Heat Exchanger; Movable cart; Brewhouse Controlling Panel; Sanitary Pump and pipe system. Fermentation system contains:2x 200L unitanks; Glycol Chiller; Movable Cart; Glycol cooling pipeline; Glycol Transfer pump; Fermentation Controlling Panel.

2.Product Advantages

- With ISO TUV SGS, the product meets GB/CE/PED/ASME standard

-Local service in EUROPE, AUSTRALIA ETC

-5 Years Warranty for tanks

-0 trade risk verified by more than 1100 breweries

3.Main Feature

-Compacted Design to Save installation space;

-Easily Movable Cart

-Stainless Steel Glycol Cooling Pipeline

-Manual Valves on Brewhouse System

-PID Automatic Fermentation Temperature Control

- Red copper for displaying in bar/pub/taproom

4. Detailed Specification

|

2 00 L Mash/Lauter Tun combined Whirlpool Tun |

Function: |

Grain Mashing, Lautering and Sparging |

|

Dimension: |

Φ 7 60x 20 00mm (Width on base of 12plato OG) |

|

|

Interior Shell: |

SUS304 full welded; TH=2mm |

|

|

Exterior Shell: |

Red copper full welded; TH=2mm |

|

|

Insulation: |

TH=50mm (environmental protection rock wool) |

|

|

Heating: |

No |

|

|

Steam Jacket: |

No |

|

|

Spent Grain Manway: |

Side mounted spent grain manhole with grain chute |

|

|

False Bottom: |

304SS wedge shape milling cut False Bottom/Filter plate with 0.7mm gap on top and 1.5mm bottom |

|

|

Wort Tangent Inlet |

Tangential whirlpool inlet at side wall |

|

|

Thermowell: |

Sanitary Thermowell for high accuracy temperature sensor |

|

|

Fixed Form: |

Legs are fixed on the movable cart |

|

|

2 00 L Kettl e Tun |

Function: |

Wort boiling, hopping and whirlpoo l |

|

Dimension: |

Φ 7 60x1800mm |

|

|

Interior Shell: |

SUS304 full welded; TH=2mm |

|

|

Exterior Shell: |

Red copper full welded; TH=2mm |

|

|

Insulation: |

TH=50mm( environmental protection rock wool) |

|

|

Heating: |

Electric, with 8Kw heating elements |

|

|

Steam Jacket: |

No |

|

|

Brewhouse Control Panel |

Function: |

Brewhouse electric controlling |

|

Electrical Parts: |

Schneider, ABB etc with CE (UL certificate for special request) |

|

|

VFD brand |

DELTA with CE/UL or DANFOSS/ABB with CE |

|

|

Part 2: Fermentation and Cooling System |

||

|

200L Beer Fermentation tank

|

Function : |

Wort Fermentation or maturation |

|

Dimension: |

Φ 810 x 1900 mm (Customizable) |

|

|

Interior Shell: |

SUS304 full welded; TH=2mm |

|

|

Exterior Shell: |

SUS304 full welded; TH=2mm |

|

|

Cooling: |

35% Glycol liquid -5℃ |

|

|

Insulation: |

TH=50mm with low thermal conductivity PU |

|

|

Cooling Jacket: |

Dimple plate on bottom and side wall, welded without over burning |

|

|

Glycol Water Chiller |

Function: |

Glycol water chilling |

|

Type: |

Air cooled glycol water chiller with 55L glycol water tank inside |

|

|

Temperature: |

Ambient Temp 35 ℃ ; Water outlet Temp -5 ℃ |

|

|

Fermentation Controlling Panel |

Function: |

Beer Fermentation controlling |

|

Electrical Parts: |

LS with CE/UL or Schneider, ABB etc with CE |

|

|

Pump Control: |

Pump on/off control |

|

|

Glycol Water Pump on/off control Auto/Manu switchable |

||

|

Chiller on/off control Auto/Manu switchable |

||

Send Inquiry>>

Click to Contact Us Now!